Refining method of rapeseed oil

A rapeseed oil and material technology, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems of increased economic cost, high oil consumption, poor removal effect of colloids such as phospholipids, etc., to increase storage time and reduce acidification speed , the effect of long storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

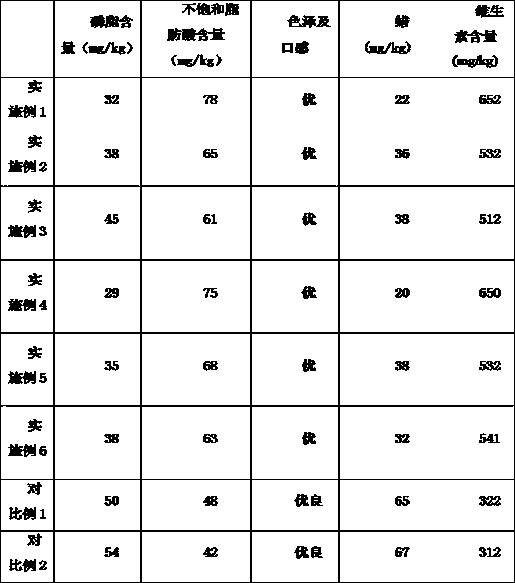

Examples

Embodiment 1

[0028] A kind of rapeseed oil refining method of the present embodiment, comprises the following steps:

[0029] Step 1, pretreatment: place the rapeseed oil at a temperature of 2°C, let it stand for 50 minutes, then perform microwave treatment, and then

[0030] Filter again to remove impurities to obtain substance A;

[0031] Step 2, degumming: heat up the substance A obtained in step 1 to 30°C, stir at a speed of 70r / min, and stir for 40min, then add tartaric acid, heat up to 40°C, continue to stir for 30min, stir at a speed of 50r / min, then add phosphoric acid, continue Stir for 45min at a stirring speed of 40r / min, then centrifuge to obtain supernatant B;

[0032] Step 3, deacidification: the supernatant B was added to a sodium carbonate solution with a mass fraction of 50%, the stirring time was 30min, and the stirring speed was 40r / min, and then added to a centrifuge for centrifugation, the centrifugation time was 35min, and the centrifugal speed was 40r / min. Substanc...

Embodiment 2

[0042] A method for refining rapeseed oil, comprising the following steps:

[0043] Step 1, pretreatment: put the rapeseed oil at a temperature of 2°C, let it stand for 50 minutes, then perform microwave treatment, and then filter to remove impurities to obtain substance A;

[0044] Step 2, degumming: heat up the substance A obtained in step 1 to 30°C, stir at a speed of 65r / min, and stir for 40min, then add tartaric acid, heat up to 40°C, continue to stir for 30min, stir at a speed of 50r / min, then add phosphoric acid, continue Stir for 45min at a stirring speed of 35r / min, then centrifuge to obtain supernatant B;

[0045] Step 3, deacidification: adding the supernatant B into the sodium carbonate solution with a mass fraction of 50%, stirring for 30 minutes at a stirring speed of 35r / min, then adding it to a centrifuge for centrifugation at a centrifugation time of 35min and a centrifugal speed of 40r / min, Substance C is obtained;

[0046] Step 4, decolorization: Stir the ...

Embodiment 3

[0055] A method for refining rapeseed oil, comprising the following steps:

[0056] Step 1, pretreatment: place the rapeseed oil at a temperature of 2°C, let it stand for 50 minutes, then perform microwave treatment, and then

[0057] Filter again to remove impurities to obtain substance A;

[0058] Step 2, degumming: heat up the substance A obtained in step 1 to 30°C, stir at a speed of 80r / min, and stir for 40min, then add tartaric acid, heat up to 40°C, continue to stir for 30min, stir at a speed of 70r / min, then add phosphoric acid, continue Stir for 45min at a stirring speed of 50r / min, then centrifuge to obtain supernatant B;

[0059] Step 3, deacidification: the supernatant B is added to the sodium carbonate solution with a mass fraction of 50%, the stirring time is 30min, and the stirring speed is 50r / min, and then added to the centrifuge for centrifugation, the centrifugation time is 35min, and the centrifugal speed is 40r / min. Substance C is obtained;

[0060] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com