A kind of composite acid for oil-water well in oil field and preparation method thereof

An oil-water well and compound acid technology, which is applied to drilling compositions, chemical instruments and methods, etc., can solve the problems of short acidification distance, large amount of acid solution, fast acid solution consumption, etc., so as to improve permeability and reduce Acidification speed, effect of reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

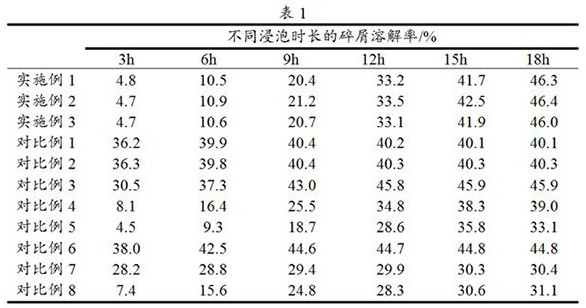

Examples

Embodiment 1

[0022] An oilfield oil-water well composite acid, the preparation method of which comprises the following steps:

[0023] Weigh half the amount of water into the mixing container, then add hydrochloric acid, boric acid, sulfamic acid, citric acid, acetic acid, aminotrimethylene phosphonic acid in sequence, and stir evenly at a speed of 100r / min to obtain mixture A; Diethylene glycol monobutyl ether and fluorine-containing surfactant, after mixing evenly, add the macromolecular complex FC, Span 80 in turn, and then add the rest of the water, stir at a temperature of 60°C at a speed of 450r / min homogeneous, stand to defoam, and obtain the complex acid of the oil-water well in the oil field.

[0024] Among them, in terms of weight percentage, it contains 5% hydrochloric acid, 5% boric acid, 2% acetic acid, 2% citric acid, 4% sulfamic acid, 5% aminotrimethylene phosphonic acid, 8% macromolecular complex FC, and Span 80 4%, SIFAST@SF-333 6%, diethylene glycol monobutyl ether 2%, w...

Embodiment 2

[0027] An oilfield oil-water well composite acid, the preparation method of which comprises the following steps:

[0028] Weigh half the amount of water into the mixing container, then add hydrochloric acid, boric acid, sulfamic acid, citric acid, acetic acid, aminotrimethylene phosphonic acid in sequence, and stir evenly at a speed of 100r / min to obtain mixture A; Diethylene glycol monobutyl ether and fluorine-containing surfactant, after mixing evenly, add the macromolecular complex FC, Span 80 in turn, and then add the rest of the water, stir at a temperature of 60°C at a speed of 450r / min homogeneous, stand to defoam, and obtain the complex acid of the oil-water well in the oil field.

[0029] Among them, in terms of weight percentage, it contains 7% hydrochloric acid, 3% boric acid, 2% acetic acid, 2% citric acid, 2% sulfamic acid, 9% aminotrimethylene phosphonic acid, 10% macromolecular complex FC, and Span 80 5%, SIFAST@SF-333 7%, diethylene glycol monobutyl ether 4%, ...

Embodiment 3

[0032] An oilfield oil-water well composite acid, the preparation method of which comprises the following steps:

[0033] Weigh half the amount of water into the mixing container, then add hydrochloric acid, boric acid, sulfamic acid, citric acid, acetic acid, aminotrimethylene phosphonic acid in sequence, and stir evenly at a speed of 100r / min to obtain mixture A; Diethylene glycol monobutyl ether and fluorine-containing surfactant, after mixing evenly, add the macromolecular complex FC, Span 80 in turn, and then add the rest of the water, stir at a temperature of 60°C at a speed of 450r / min homogeneous, stand to defoam, and obtain the complex acid of the oil-water well in the oil field.

[0034] Wherein, by weight percentage, the compound acid contains 15% of hydrochloric acid, 2% of boric acid, 1% of acetic acid, 1% of citric acid, 2% of sulfamic acid, 4% of aminotrimethylene phosphonic acid, and 15% of macromolecular complex FC , Span 80 8%, SIFAST@SF-333 10%, diethylene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com