Cheese and its preparation method

A technology of cheese and curd, applied in the field of cheese and its preparation, to achieve the effect of rich nutrition and strong stringiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

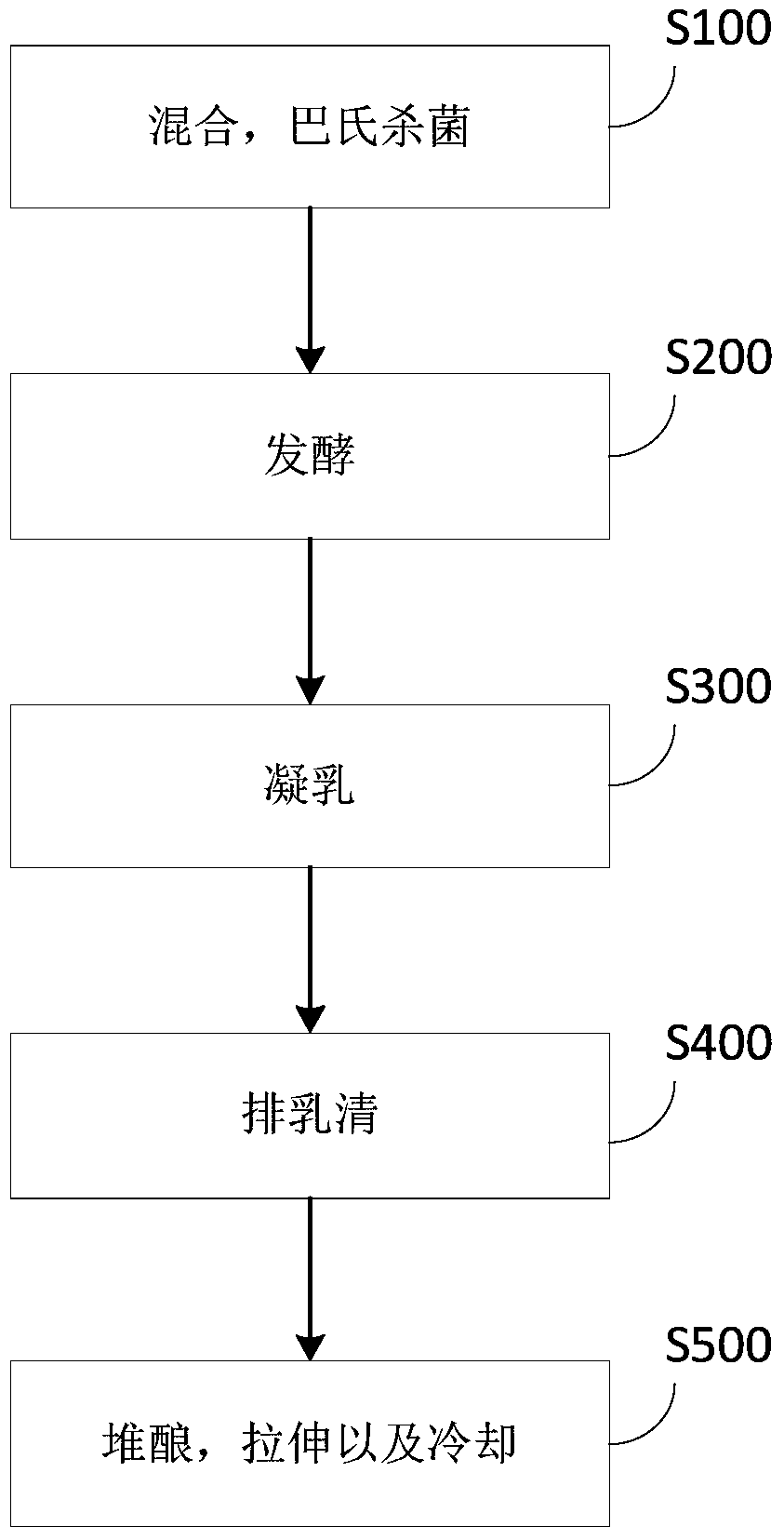

Method used

Image

Examples

preparation example Construction

[0058] The cheese obtained by the method for preparing cheese according to the embodiment of the present invention can be stored at 2-6 degrees Celsius.

[0059] Those skilled in the art can understand that the features and advantages described above for the method for preparing cheese are also applicable to the cheese, and will not be repeated here.

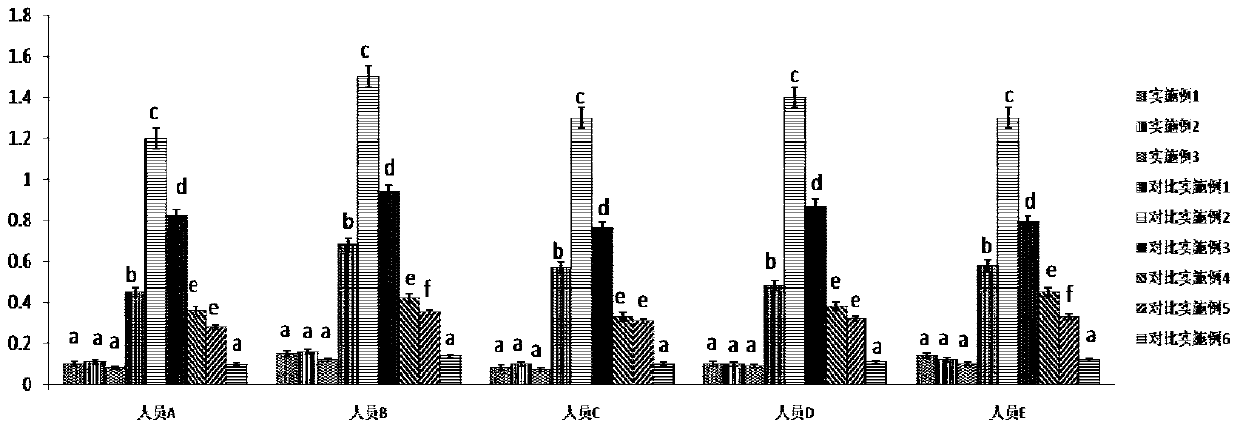

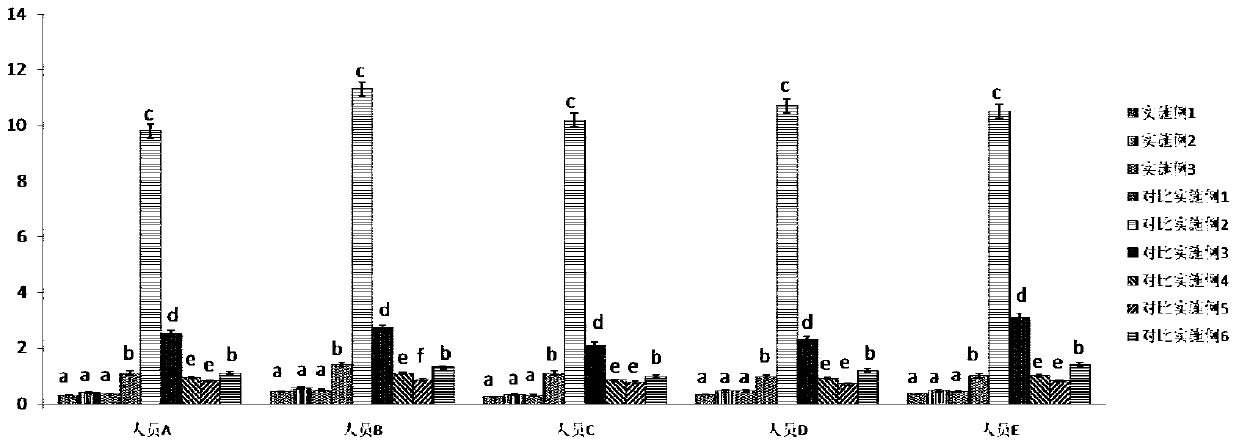

[0060] To sum up, according to the embodiments of the present invention, the cheese of the present invention and its preparation method have at least one of the following advantages:

[0061] 1. According to an embodiment of the present invention, by adding microcrystalline cellulose and sodium carboxymethyl cellulose to maintain the stringiness of cheese during the shelf life.

[0062] 2. According to the embodiment of the present invention, cooling treatment is carried out after cutting to reduce the activity of rennet, and control the acidification time of the curd from cutting to pH 5.4 to 5.8, and reduce the acidification s...

Embodiment 1

[0065] In this example, cheese was prepared by the following steps:

[0066] (1) Raw milk is standardized, wherein the fat: protein ratio is 0.7:1, then 1000 kg of raw milk, 0.08 kg of microcrystalline cellulose and 0.02 kg of carboxymethyl cellulose sodium are fully mixed evenly, and heated at 72 degrees Celsius Pasteurize at low temperature for 15 seconds and cool to 34 degrees Celsius;

[0067] (2) Add 25U Streptococcus thermophilus ST-M8, and ferment for 15 minutes at a temperature of 34 degrees Celsius;

[0068] (3) Add 10 grams of rennet and 1 kilogram of calcium chloride, and curd the milk for 25 minutes at a temperature of 34 degrees Celsius;

[0069] (4) Cut the curd after the curd into 8cm × 8cm × 8cm, then keep it at a temperature of 34 degrees Celsius and let it stand until the pH value is 6.50, then cool down to 33 degrees Celsius and keep it warm for 10 minutes;

[0070] (5) Heating and stirring to raise the temperature to 39 degrees Celsius, the fermentation a...

Embodiment 2

[0074] In this example, cheese was prepared by the following steps:

[0075] (1) Raw milk is standardized, wherein the fat: protein ratio is 1.2:1, then 1000 kg of raw milk, 0.4 kg of microcrystalline cellulose and 0.1 kg of carboxymethyl cellulose sodium are fully mixed and heated at 74 degrees Celsius Pasteurize at low temperature for 15 seconds and cool to 36 degrees Celsius;

[0076] (2) Add 50 U of Streptococcus thermophilus TCC-3, and ferment at 36 degrees Celsius for 60 minutes;

[0077] (3) Add 20 grams of rennet and 0.1 kilogram of calcium chloride, and curd the milk for 45 minutes at a temperature of 36 degrees Celsius;

[0078] (4) Cut the curd curd into 8cm × 8cm × 8cm, then keep it at a temperature of 36 degrees Celsius and let it stand until the pH value is 6.40. When the temperature is 6.40, the temperature is lowered to 33 degrees Celsius, and the temperature is kept for 30 minutes;

[0079] (5) Heating and stirring to raise the temperature to 41 degrees Celsiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com