Method of constructing highly corrosion-resistant zinc alloy double-coating on surface of steel product

A zinc alloy, high corrosion resistance technology, applied in metal material coating process, coating, hot-dip plating process, etc., can solve problems such as difficult plating, to prolong service life, process stability, improve coating corrosion resistance effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

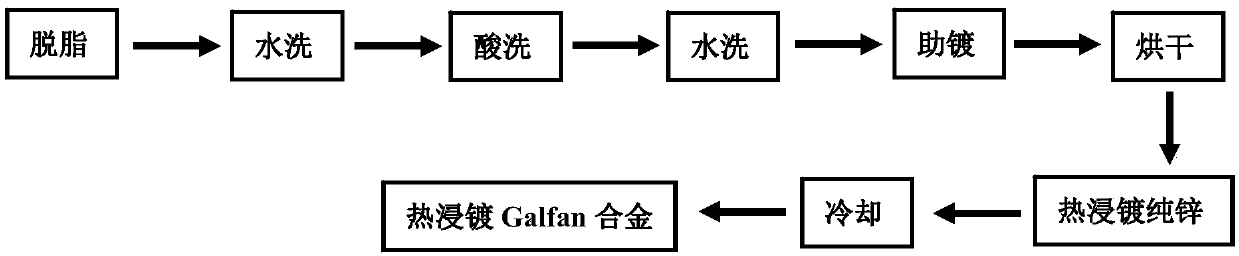

[0034] Take the pre-plating of pure zinc coating and then Galfan coating as an example. process such as figure 2 As shown, the technological process for preparing a high corrosion-resistant Galfan alloy layer is degreasing, water washing, pickling, water washing, fluxing, drying, hot-dip pure zinc plating, cooling, hot-dip Galfan alloy plating, and cooling. The details of each process are as follows:

[0035] (1) Hang the 08F low-silicon steel test piece (3cm×4cm×2mm), then place it in a 70°C, 20wt% NaOH solution for degreasing for 2 minutes, and then rinse it with 80°C hot water;

[0036](2) Soak the low-silicon steel test piece washed in step (1) in hydrochloric acid with a concentration of 15wt% for 5 minutes, and then rinse it with water;

[0037] (3) Soak the low-silicon steel test piece rinsed in step (2) in a 70°C fluxing solution (15wt% NH 4 Cl, 15 wt% ZnCl 2 , and the rest is water) for 1 min, then take it out and dry it;

[0038] (4) Soak the low-silicon steel ...

Embodiment 2

[0043] Take the pre-plating of pure zinc coating and then Galfan coating as an example. process such as figure 2 As shown, the technological process for preparing a high corrosion-resistant Galfan alloy layer is degreasing, water washing, pickling, water washing, fluxing, drying, hot-dip pure zinc plating, cooling, hot-dip Galfan alloy plating, and cooling. The details of each process are as follows:

[0044] (1) Hang the 08F low-silicon steel test piece (3cm×4cm×2mm), then place it in a 70°C, 20wt% NaOH solution for degreasing for 2 minutes, and then rinse it with 80°C hot water;

[0045] (2) Soak the low-silicon steel test piece washed in step (1) in hydrochloric acid with a concentration of 15wt% for 5 minutes, and then rinse it with water;

[0046] (3) Soak the low-silicon steel test piece rinsed in step (2) in a 70°C fluxing solution (15wt% NH 4 Cl, 15 wt% ZnCl 2 , and the rest is water) for 1 min, then take it out and dry it;

[0047] (4) Soak the low-silicon steel...

Embodiment 3

[0051] Take the pre-plating of pure zinc coating and then Galfan coating as an example. process such as figure 2 As shown, the technological process for preparing a high corrosion-resistant Galfan alloy layer is degreasing, water washing, pickling, water washing, fluxing, drying, hot-dip pure zinc plating, cooling, hot-dip Galfan alloy plating, and cooling. The details of each process are as follows:

[0052] (1) Hang the 08F low-silicon steel test piece (3cm×4cm×2mm), then place it in a 70°C, 20wt% NaOH solution for degreasing for 2 minutes, and then rinse it with 80°C hot water;

[0053] (2) Soak the low-silicon steel test piece washed in step (1) in hydrochloric acid with a concentration of 15wt% for 5 minutes, and then rinse it with water;

[0054] (3) Soak the low-silicon steel test piece rinsed in step (2) in a 70°C fluxing solution (15wt% NH 4 Cl, 15 wt% ZnCl 2 , and the rest is water) for 1 min, then take it out and dry it;

[0055] (4) Soak the low-silicon steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com