Prefabricated fabricated bridge pier and assembling construction method thereof

A prefabricated assembly and construction method technology, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve problems such as inapplicability, and achieve the effect of small occupied space, accelerated construction progress, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

[0039] The prefabricated piers can be hollow or solid, and the cross-section can be circular, rectangular or square. It can be fixed or variable cross-section. Now take the circular cross-section solid flowerpot-type piers as an example to illustrate :

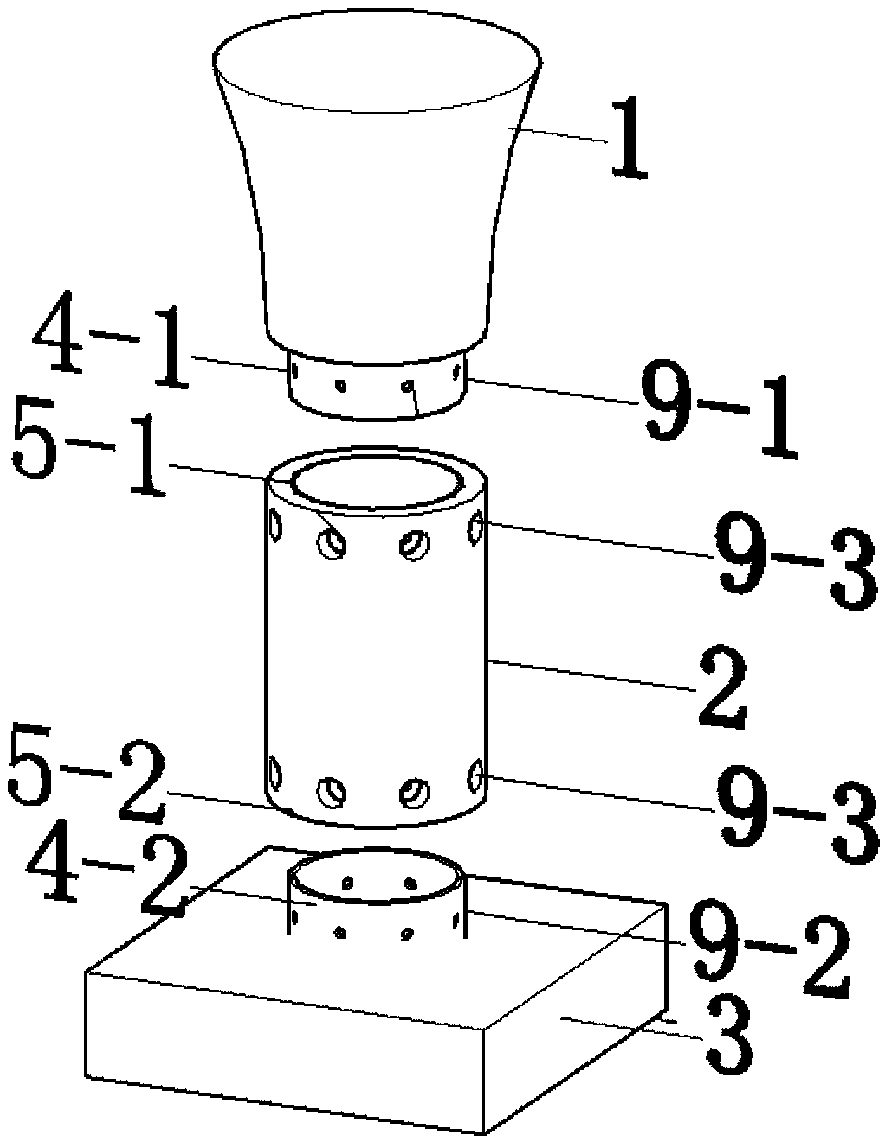

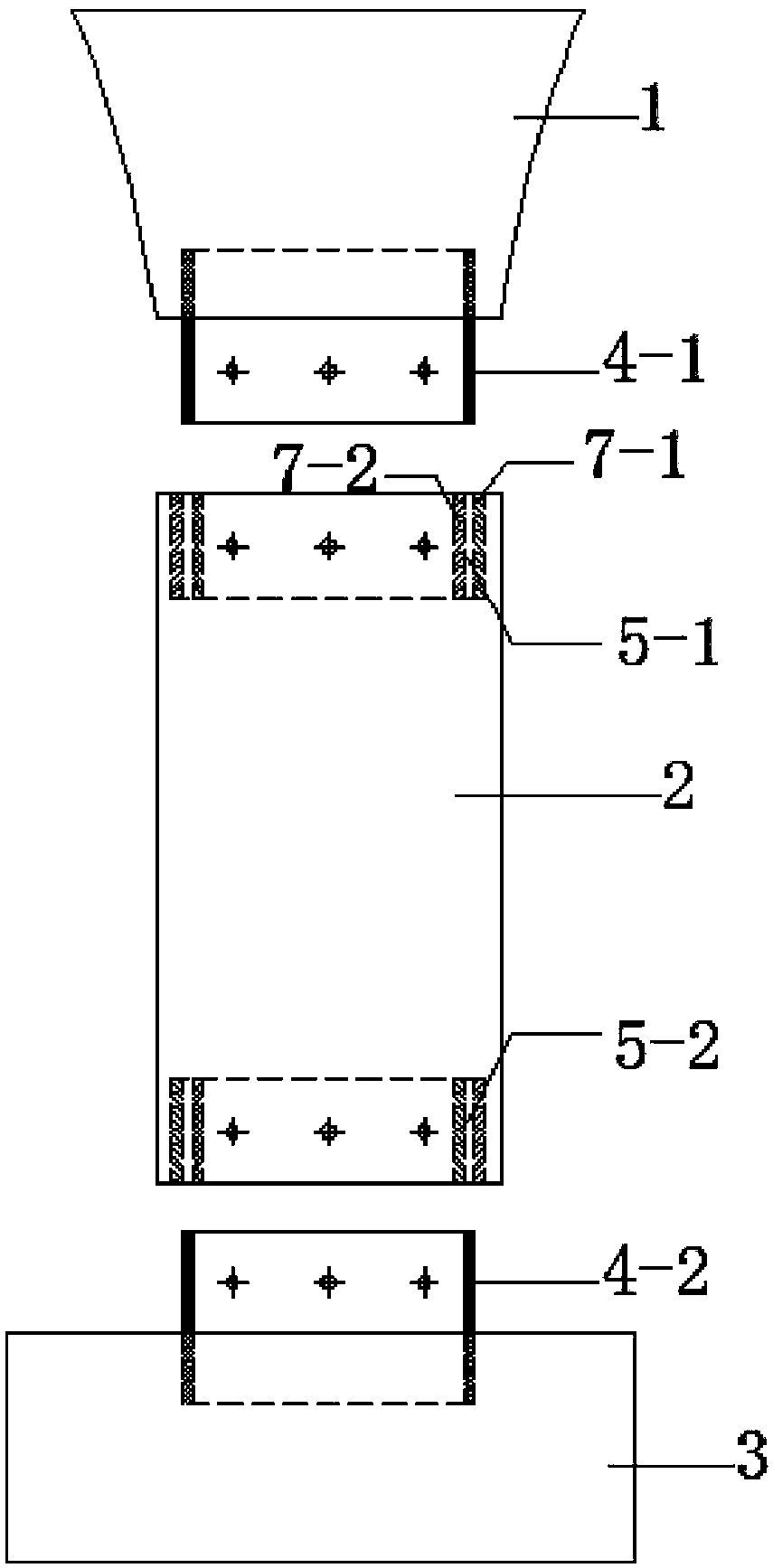

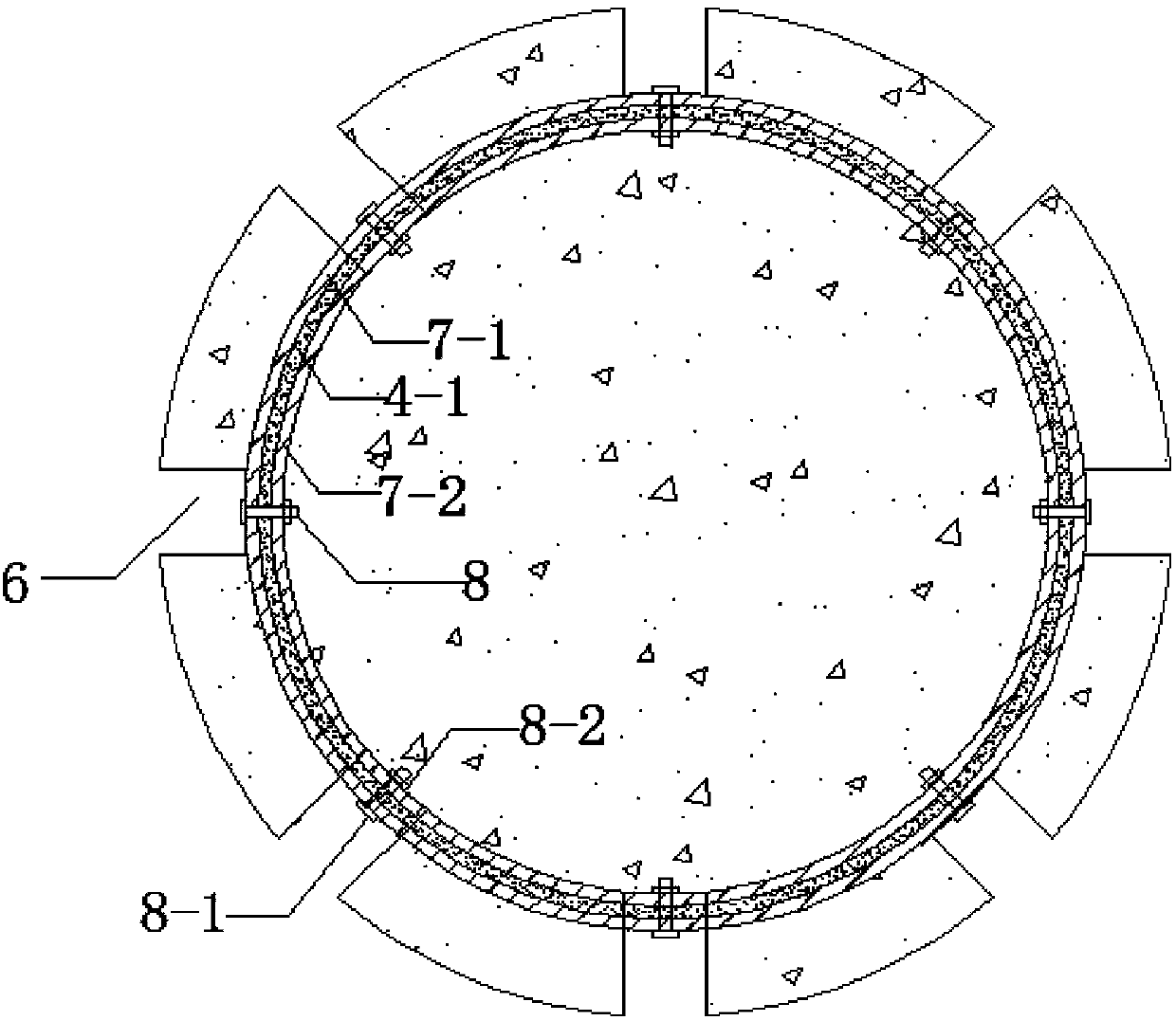

[0040] A prefabricated bridge pier, such as figure 1 , figure 2 As shown, it includes pier cap segment 1, pier body segment 2 and cap 3; the length of the circular upper built-in steel casing 4-1 protruding from the bottom of pier cap segment 1 is 30cm, and the upper built-in steel casing Eight upper anchor holes 9-1 are evenly distributed on the barrel wall of the casing 4-1; the top of the cap 3 protrudes from a circular lower built-in steel casing 4-2, the length of which is 30cm, and the lower built-in steel protection Eight lower anchor holes 9-2 are evenly distributed on the barrel wall of the barre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Total length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com