Walking pile frame

A walking type, pile frame technology, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve the problems of reduced axial bearing capacity of columns, reduced stability against compression, limited reset force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

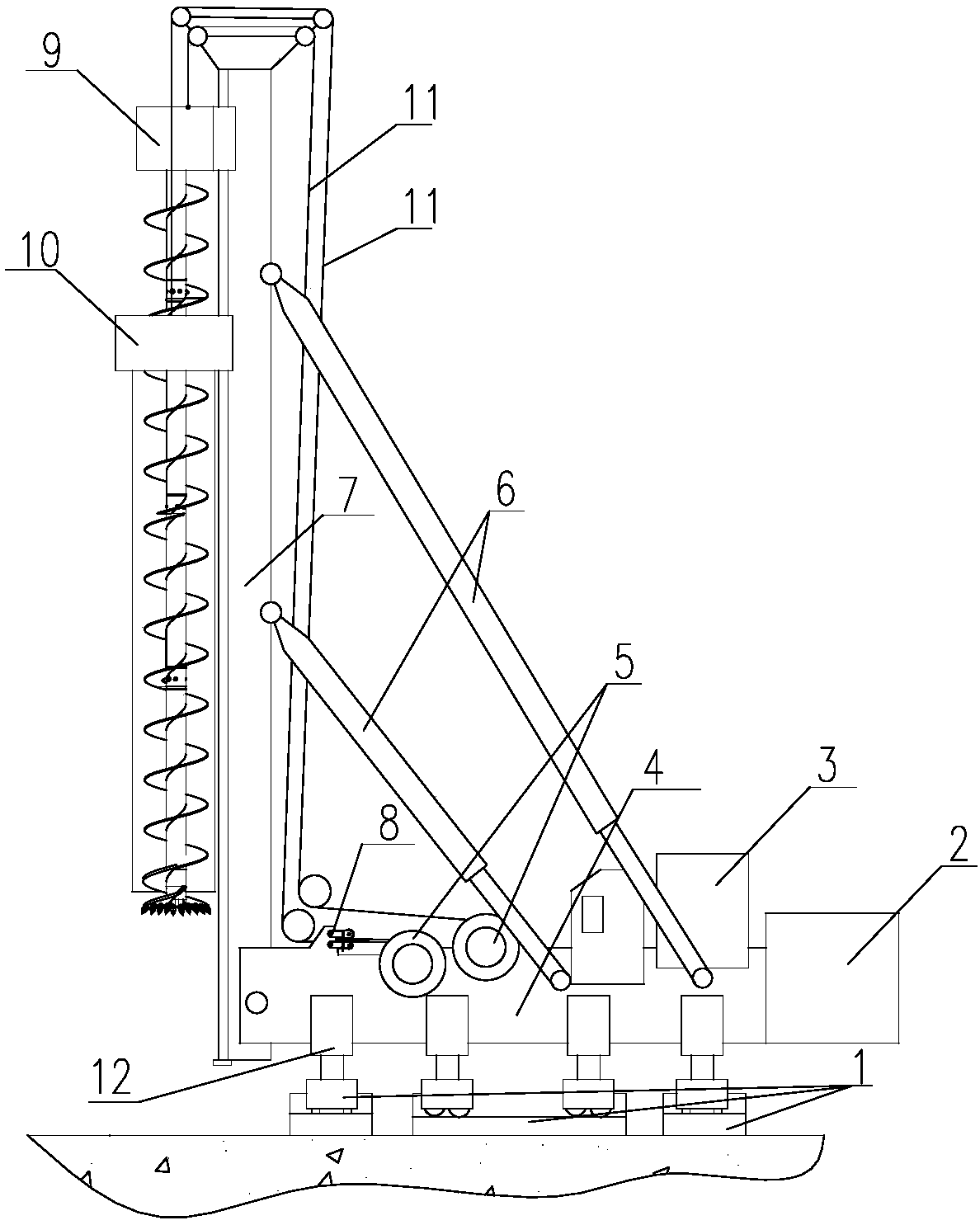

[0038] see figure 1 with figure 2 , the walking pile frame in the illustration is a preferred solution of the present invention, specifically including a walking chassis 1, a hydraulic power station 2, a pile frame power system 3, a fuselage 4, a winch unit 5, an inclined support rod 6, a column 7, Depth detection device 8 , auger drilling device 9 , casing drilling device 10 , wire rope 11 and support leg 12 .

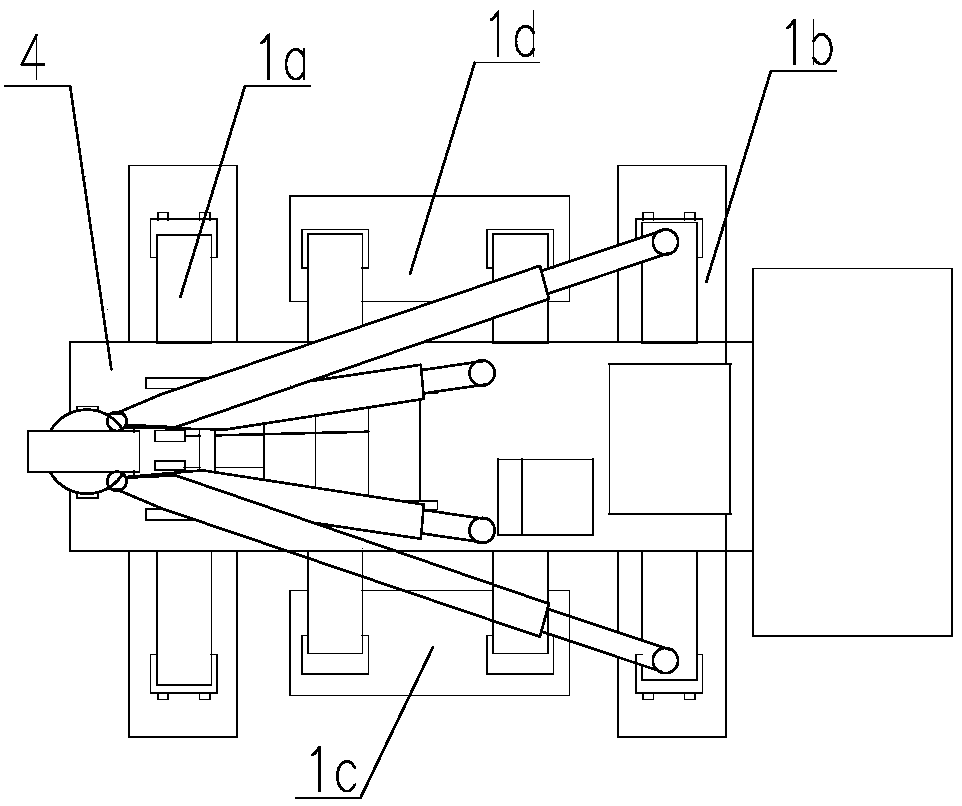

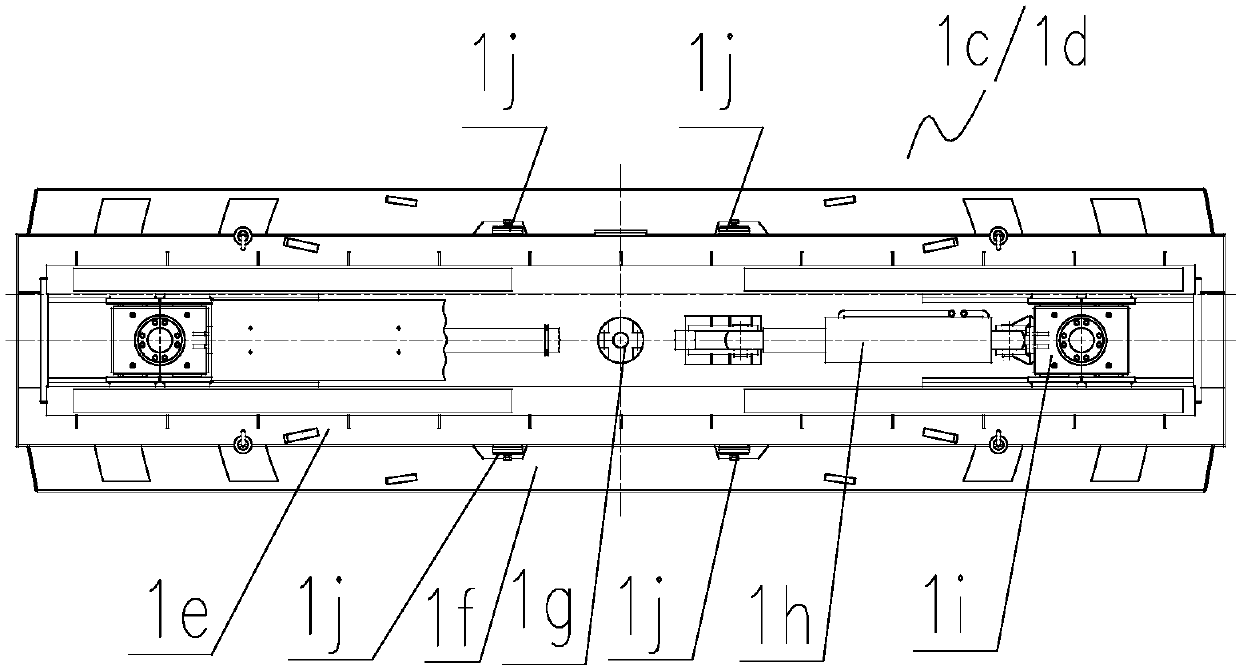

[0039] Specifically, the walking chassis 1 includes a front traversing mechanism 1a, a rear traversing mechanism 1b, a left longitudinal movement turning mechanism 1c, and a right longitudinal movement turning mechanism 1d. And on the longitudinal movement and slewing mechanism, the lower end of the column 7 is hinged at the front end of the fuselage 4, and two pairs of oblique support rods 6 are respectively connected between the column 7 and the fuselage 4 to form two sets of symmetrical triangular support structures; two sets of hoisting units 5 is set on the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com