Cold-heading-formed blank of pipeline joint

A technology of pipe joints and cold heading, which is applied in the direction of pipes/pipe joints/fittings, passing components, mechanical equipment, etc., and can solve problems such as large volume, low material utilization rate, and large blank allowance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

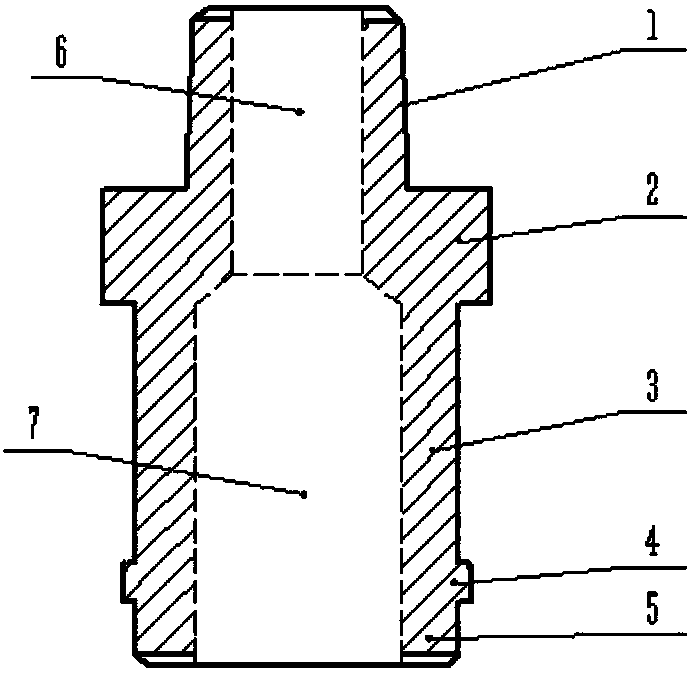

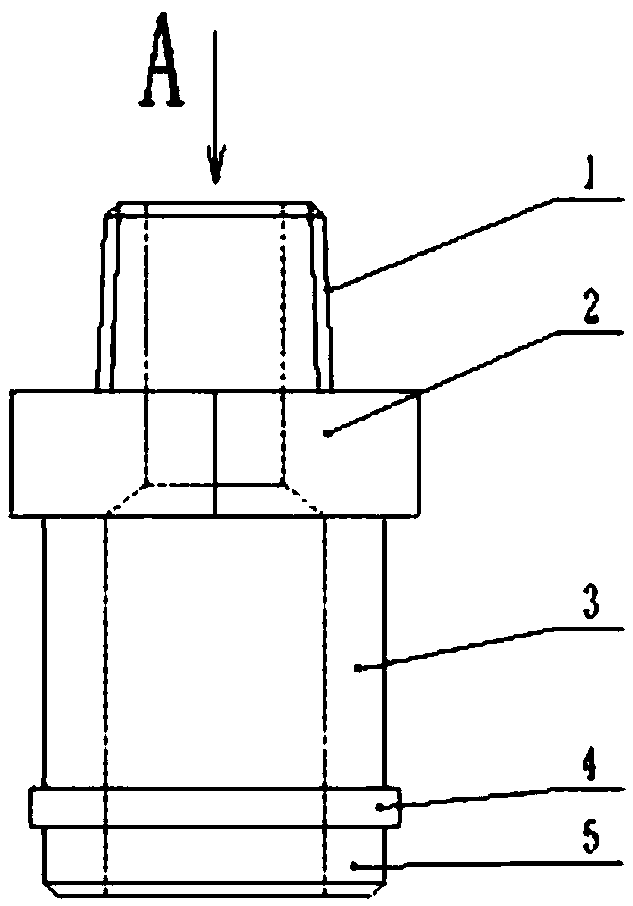

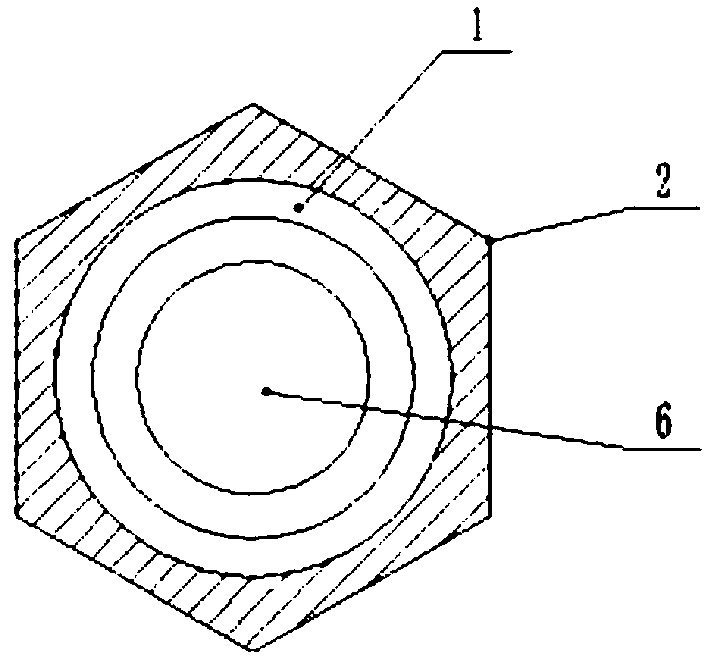

[0011] Attached below Figure 1-Figure 3 A pipe joint cold heading forming blank of the present invention will be further described in detail.

[0012] In order to achieve the above object, the present invention provides a pipe joint cold heading forming blank, which is characterized in that the blank is composed of: a small head (1), a mounting boss (2), a middle section (3), a raised ring (4), and a tail end (5), composed of small channel (6), large channel (7), described small head (1), outer hexagonal shape (2), middle section (3), raised ring (4) and tail end (5) Cold heading into a whole, the small head (1) is made into a conical shape with a small top and a big bottom, and the outer circle of the upper end of the small head (1) is chamfered, and the outer circle of the lower end of the tail end (5) is also chamfered Corner treatment.

[0013] The present invention is a pipe joint cold heading forming blank, which is characterized in that: the mounting boss (2) is made...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap