Drying unit for golden camellia flower tea production

A drying device, golden camellia technology, applied in drying, drying machine, biomass drying, etc., can solve the problems such as the number of flower teas is easy to pile up, the temperature loss of the drying device, and the drying effect is not good. Achieve the effect of enhanced drying effect, simple structure and compact connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

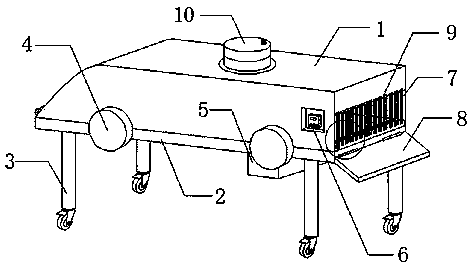

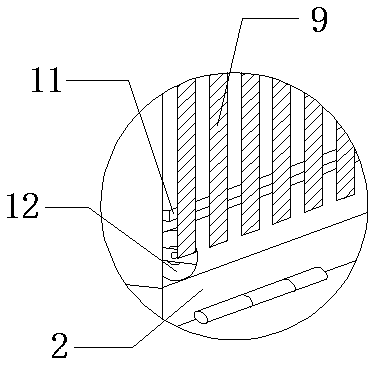

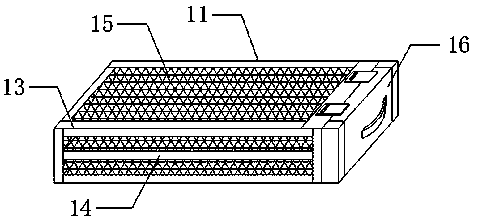

[0024] see Figure 1-5 As shown, a drying device for the production of Camellia japonica flower tea, comprising a drying box 1 and a tea storage box 11, a bottom plate 2 is arranged at the bottom of the drying box 1, and several supporting legs 3 are set under the bottom plate 2, and the bottom plate The bottom of 2 is provided with a power supply block 5, the top of the power supply block 5 is provided with a control panel 6, a group of hot air blowers 4 are arranged on both sides of the drying box 1, and one end of the drying box 1 is provided with a feed inlet 7, and the A box door 8 is installed on one side, and the inside of the drying box 1 can be overhauled by opening the box door 8. Several cloth strips 9 are arranged inside the feed port 7, and a ferrule 19 is arranged on the top of the drying box 1. The top of the ferrule 9 Threaded joint 18 is set, and water storage barrel 10 is installed on the top of threaded joint 18, and water exchange port 17 is arranged on the...

Embodiment 2

[0026] In addition, refer to Figure 1-5 , differ from the first embodiment above, the water storage bucket 10 is connected to the ferrule 19 through the threaded joint 18, and the inner diameter of the ferrule 19 is larger than the diameter of the sponge pad 23, so that the water storage bucket 10 can be easily removed from the ferrule 19, which is convenient Replace the sponge pad 23 to prevent water vapor from condensing too much to gather and fall. The two sets of hot air blowers 4 are diagonally arranged, and the position of the hot air blowers 4 with low vertical height is higher than the roller 12, so that the two sets of hot air blowers 4 Hot air convection can be formed between them, so that the temperature inside the drying box 1 is rapidly increased, the door 8 is movably connected with the drying box 1, and the tea storage box 11 and the roller 12 are movably connected, so that the box door 8 It is convenient to open, and the tea storage box 11 can be conveniently ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com