Light diffusion plate and preparation method thereof

A light-diffusing plate and light-diffusing particle technology, which is applied in optics, optical components, instruments, etc., can solve the problems of impact resistance decline and other problems, and achieve the effect of improving impact strength, high impact strength, and increasing interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

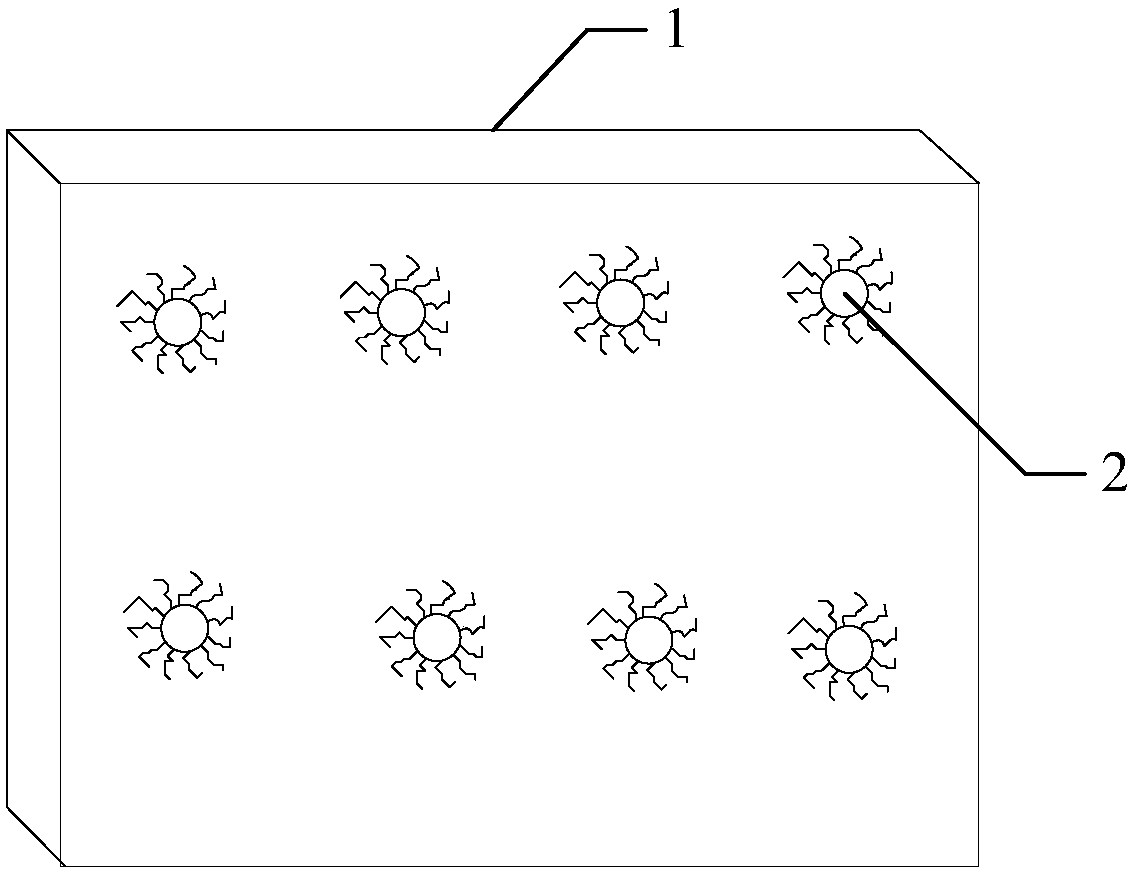

[0023] The present invention provides a method for preparing a light scattering plate, the method comprising:

[0024] Step 1: Prepare light scattering particles with surface connected molecular chains;

[0025] Step 2: Take the light scattering particles and the transparent substrate to mix according to the mass percentages of 0.1-25% and 75-99.9% respectively, and blend and extrude them under the conditions of 180°C to 300°C to obtain the light scattering plate.

[0026] Among them, the molecular chain connected to the light scattering particles is the same as the molecular chain of the transparent substrate.

[0027] Further, the method for preparing light scattering particles with surface connected molecular chains includes:

[0028] According to the mass ratio of 1:0.2~2:10~100, mix the microspheres carrying hydroxyl and double bonds on the surface, the monomer or oligomer for preparing transparent substrate, and the organic solvent, and then drop the initiator to react at 50~100℃....

Embodiment 1

[0035] According to the mass ratio of 1:0.2:50, organic silicon microspheres with a particle size of 1 μm and hydroxyl and double bonds on the surface, polycarbonate with a molecular weight of 100 to 500 and chloroform were mixed, and the total mass of the system was dropped at 60°C. 0.5% sodium alkoxide, reacted for 5 hours, filtered, washed, filtered and dried to obtain organosilicon microspheres with polycarbonate molecular chains connected on the surface.

[0036] The organic silicon microspheres with a mass fraction of 1% and polycarbonate with a mass fraction of 99% are blended, and a light diffusion plate with a thickness of 2000 μm is extruded.

Embodiment 2

[0038] According to the mass ratio of 1:1:20, the organosilicon microspheres with a particle size of 1μm and carrying hydroxyl and double bonds on the surface, methyl methacrylate and toluene were mixed, and at 70℃, 5% of the total mass of the system Nitrogen diisobutyronitrile reacted for 10 hours, filtered, washed, filtered and dried to obtain organosilicon microspheres with polymethyl methacrylate molecular chains connected on the surface.

[0039] The organic silicon microspheres with a mass fraction of 1% and polymethyl methacrylate with a mass fraction of 99% are blended, and a light diffusion plate with a thickness of 1000 μm is extruded.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com