Method for extracting tobacco surface terpene and sugar ester compounds by utilizing tobacco land waste and application thereof

A technology of tobacco waste and diterpenes, which is applied in the fields of tobacco, application, and preparation of tobacco, can solve the problems of complex aroma components in cigarettes, cumbersome extraction steps, and expensive instruments and equipment, so as to facilitate mass production and enrich the tobacco itself. Fragrance, the effect of high added value utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Preparation of tincture of aroma components on the surface of tobacco

[0026] 1. Sampling

[0027] Select 667m 2 The planted flue-cured tobacco variety is Hongda, and during the flowering period of the tobacco field, fresh topping discarded inflorescences, axillary buds and tobacco leaves of unsuitable grades are collected.

[0028] 2. Leaching

[0029] The above-mentioned fresh raw materials are directly extracted without being dried and pulverized. The solvent is absolute ethanol, and the amount of solvent used is 1.2 times the volume of the raw material. All the raw materials are continuously extracted twice, and the extraction time is 2 minutes each time. The extraction liquid is recycled. solvent, and all extracts were combined and filtered to obtain 120L extract.

[0030] 3. Concentrate

[0031] The extract was concentrated to 20 L under reduced pressure at 50° C., and the solvent was recovered.

[0032] 4. Purification

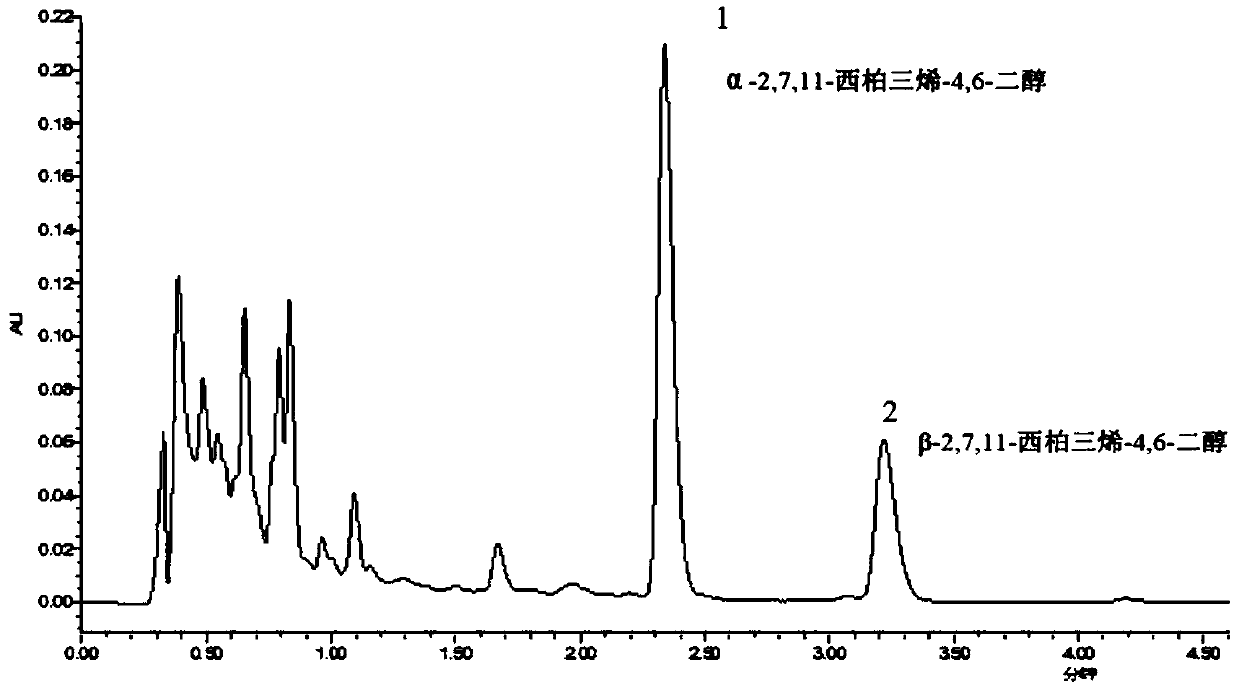

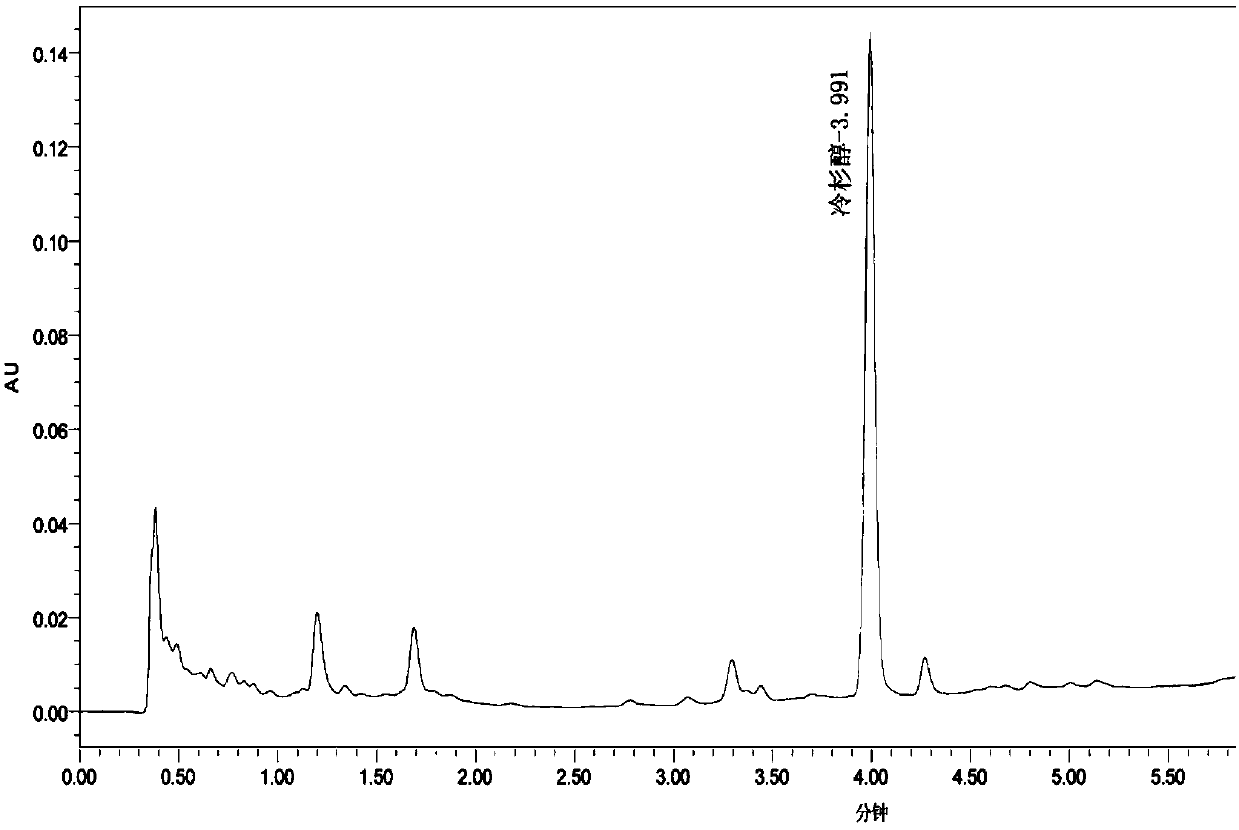

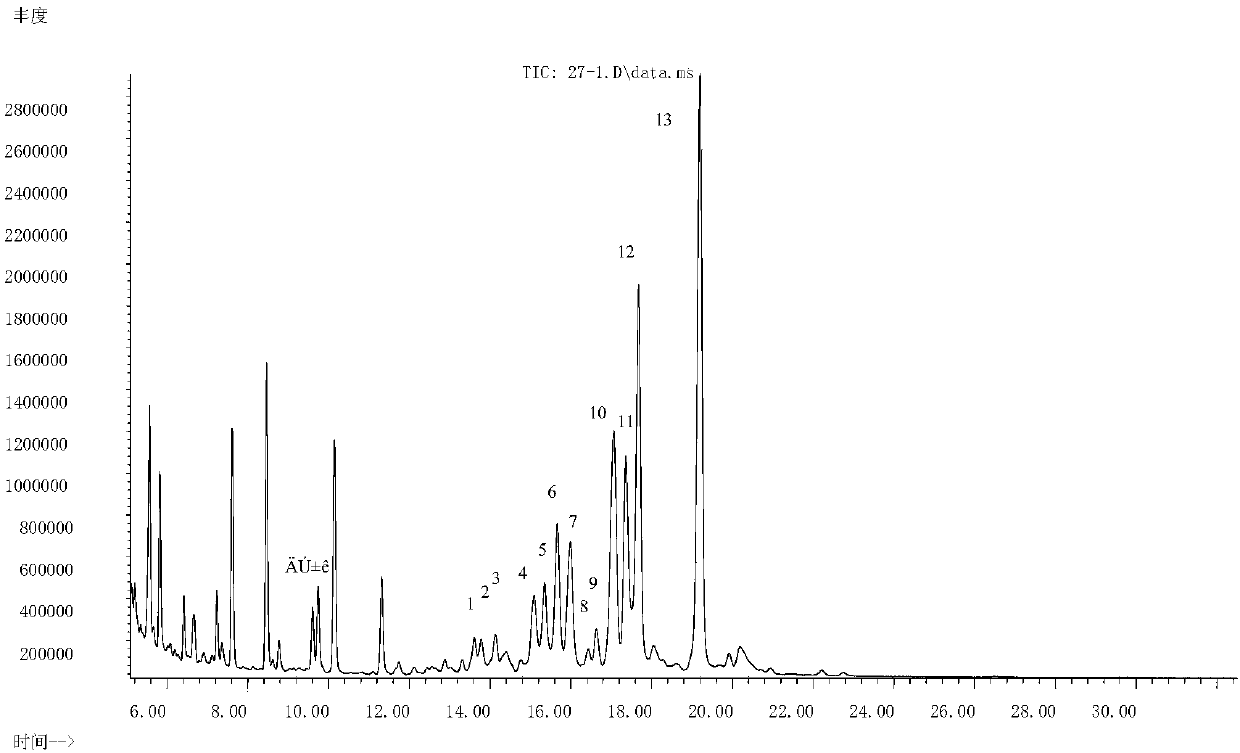

[0033] The concentrated solutio...

Embodiment 2

[0044] 1. Preparation of tincture of aroma components on the surface of tobacco

[0045] 1. Sampling

[0046] Select 667m 2 The oriental tobacco variety Shamson planted, during the flowering period of the tobacco field, is topped to collect fresh inflorescences and axillary buds.

[0047] 2. Leaching

[0048] The above-mentioned fresh raw materials are directly extracted without being dried and pulverized. The solvent is absolute ethanol, and the amount of solvent is 1.5 times the volume of the raw material. All the raw materials are continuously extracted twice, and the extraction time is 3 minutes each time. The extraction solution is recycled. Solvent, and all extracts were combined, filtered to obtain 180mL initial extract.

[0049] 3. Concentrate

[0050] The extract was concentrated under reduced pressure at 60°C to 30 mL, and the solvent was recovered.

[0051] 4. Purification

[0052] The concentrated solution was left to stand at 8°C for 4 hours, and flocculent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com