Method for extracting nonpolar substances from oil-based drilling cuttings and extraction device

An extraction device and oil-based drilling cuttings technology, applied in the field of methods and extraction devices, can solve the problems of high recovery rate of base oil, low operating cost, and low efficiency of oil-based drilling cuttings, so as to avoid blockage of pipelines and pressure field evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

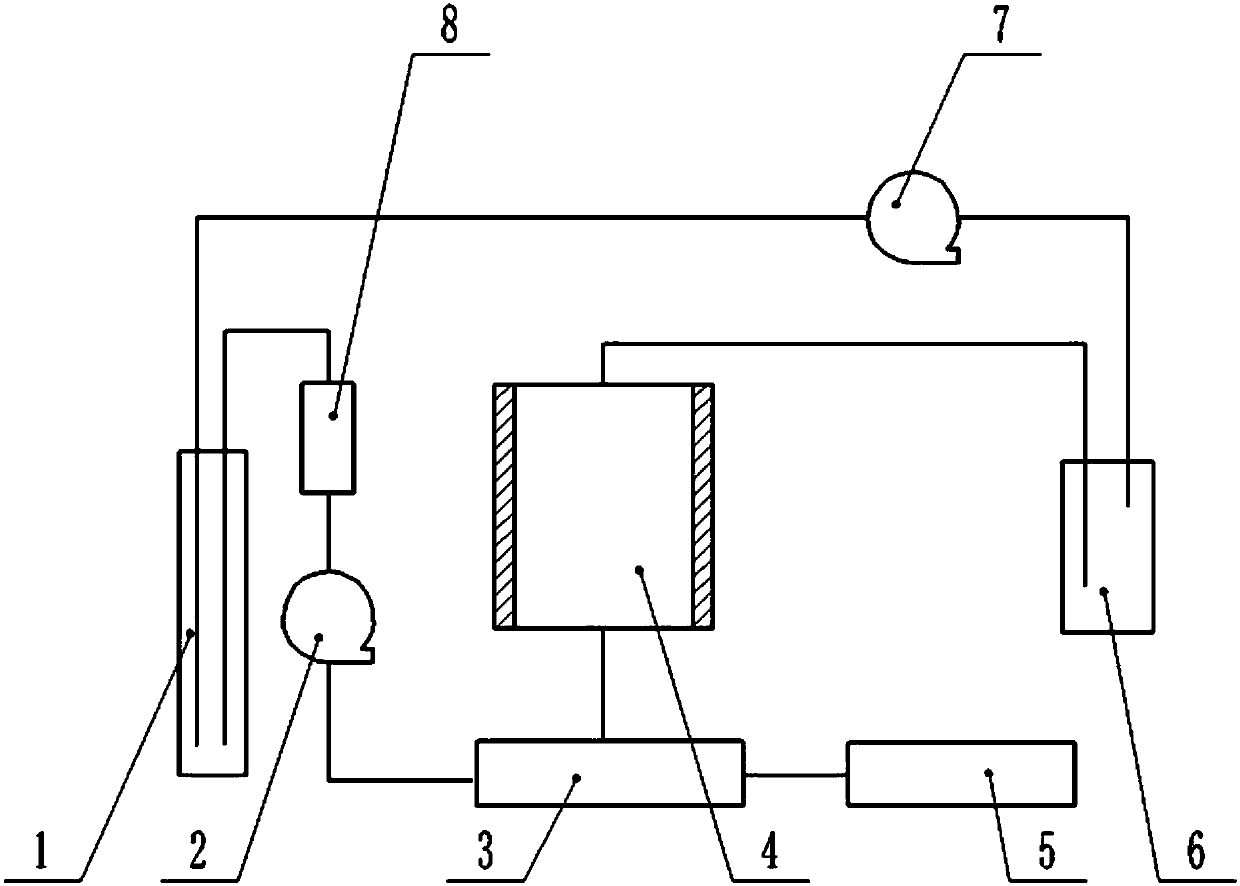

[0032] An extraction device, including a liquid storage tank 1, a water cooling device 8, a high-pressure pump 2, an intermediate storage tank 3, an extraction kettle 4, and a separation kettle 6 connected in sequence, and a compressor is also arranged between the separation kettle and the liquid storage tank. Pump 7, the discharge port of the separation tank is connected with the feed port of the liquid storage tank through a compression pump.

[0033] It also includes a heater 5, an insulation layer is provided on the outside of the intermediate storage tank, an insulation layer is provided on the outside of the extraction kettle, and the heater is connected to the insulation layer.

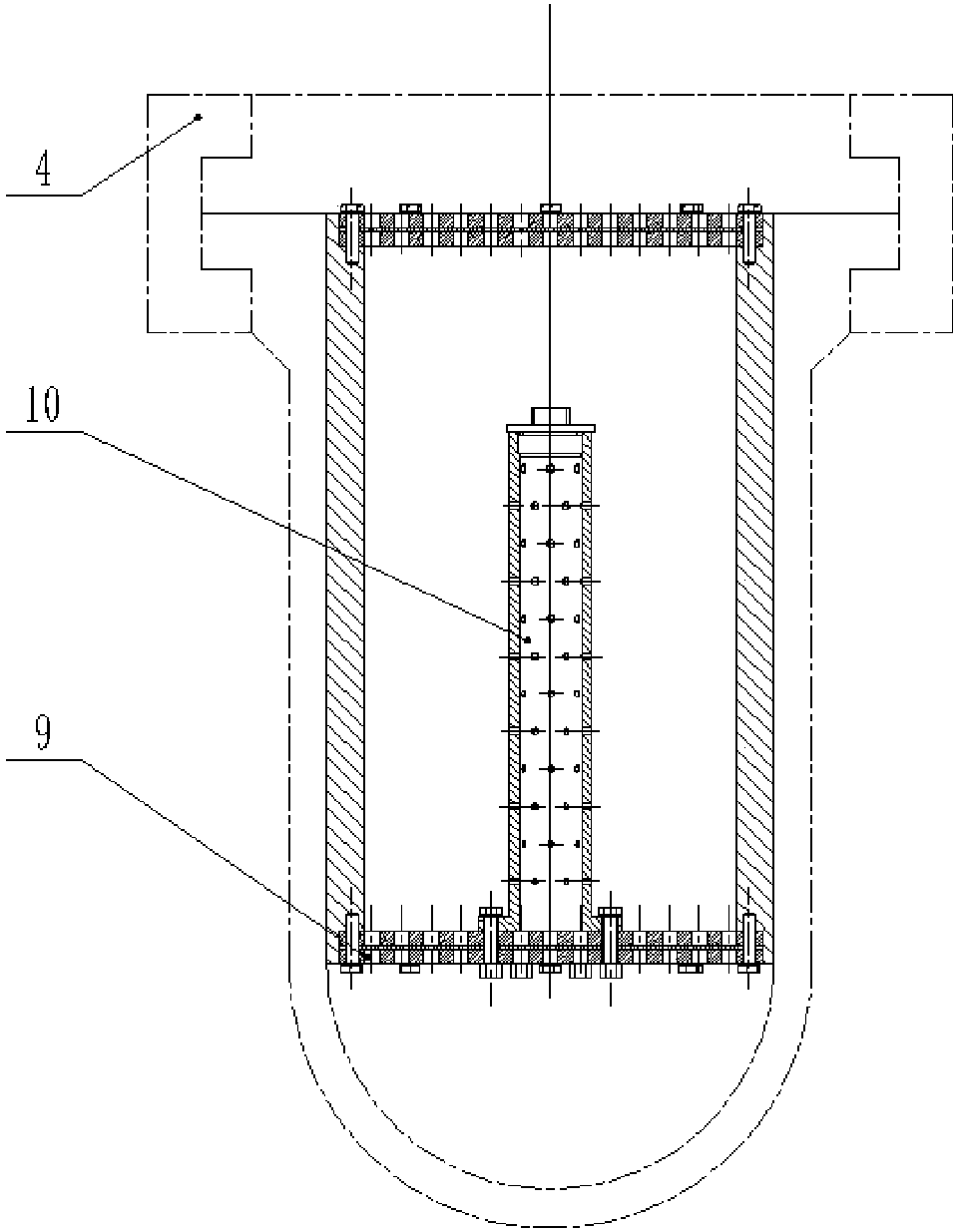

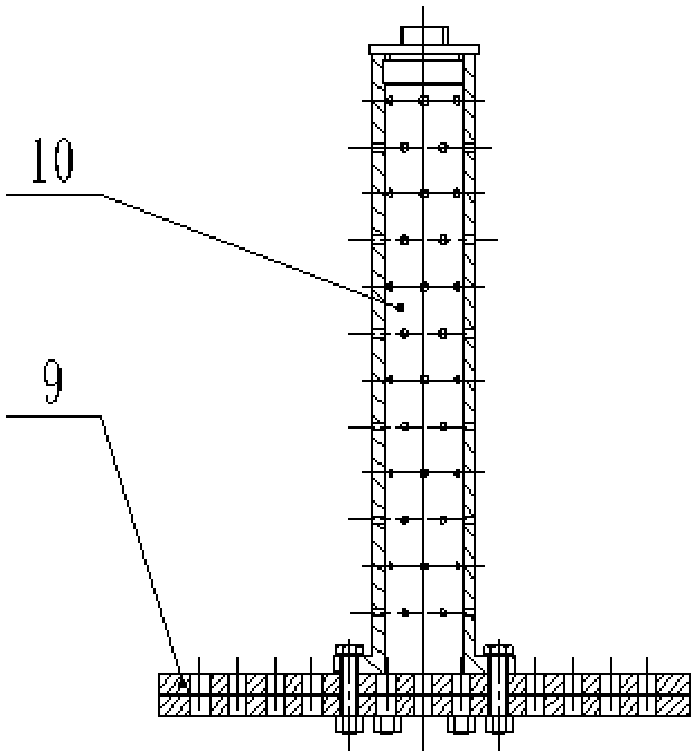

[0034] The extraction kettle is a cylinder, and the two ends of the cylinder have end covers, which are the upper cover and the lower cover respectively, and sealing rings are arranged between the upper cover, the lower cover and the cylinder body, and the upper and lower covers are realized by ...

Embodiment 2

[0037] A method for extracting non-polar substances from oil-based drilling cuttings using the extraction device described in Example 1, the specific steps are as follows:

[0038] (1) Take 160Kg of oil-based drilling cuttings (oil content 18%, density 2.0g / cm2) from Well Coke Page 27-1HF 3 ), put into the 100L extractor;

[0039] (2) Raise the temperature of the extraction kettle to 35°C, separate the kettle, and raise the inlet temperature to the separation temperature of 60°C, and turn on the high-pressure pump for continuous operation to make the liquid CO 2 into supercritical CO 2 Fluid, and stabilized for 5-10min, so that the pressure during the extraction process is 10MPa;

[0040] (3) Open the inlet valve on the lower part of the extraction kettle and the outlet valve on the upper part, and open the separation kettle at the same time, supercritical CO 2 And the extracted non-polar substances flow out of the extraction kettle, CO 2 The fluid is expanded and separate...

Embodiment 3

[0044] A method for extracting non-polar substances from oil-based cuttings using the extraction device described in Example 1, wherein the extraction temperature is 35°C, the pressure is 12MPa, the temperature of the separation process is 60°C, and the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com