Intelligent LNG power generation ship

A technology for liquefied natural gas and power generation ships, which is applied in gaseous engine fuels, ship construction, and ship parts, etc., can solve problems such as the inability of power generation ships to adjust themselves, waste of energy consumption, and hidden safety hazards, and achieve the effect of stable and reasonable gas supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

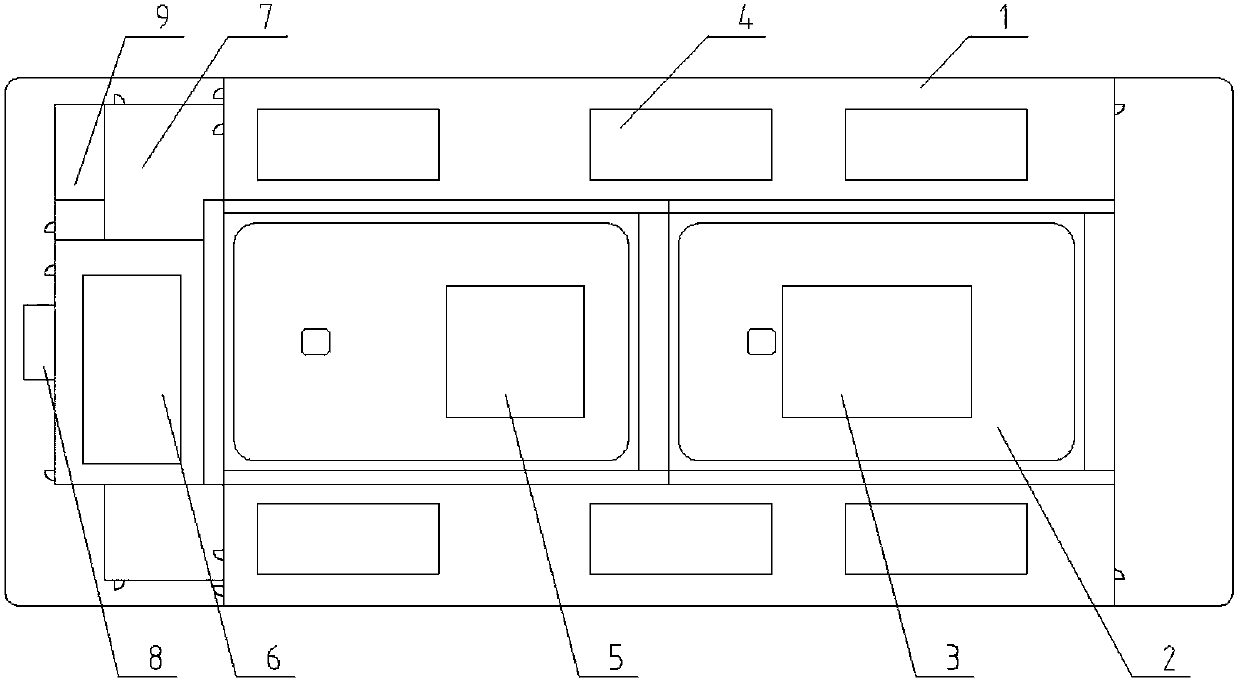

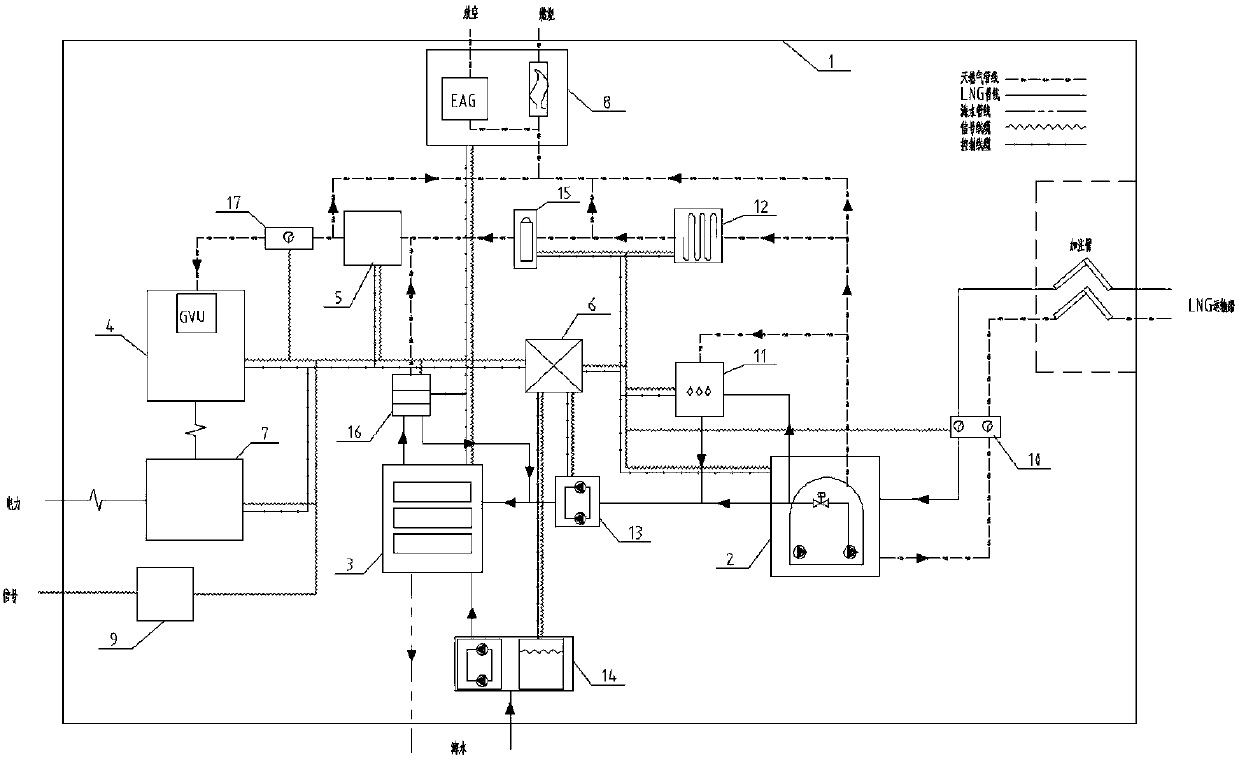

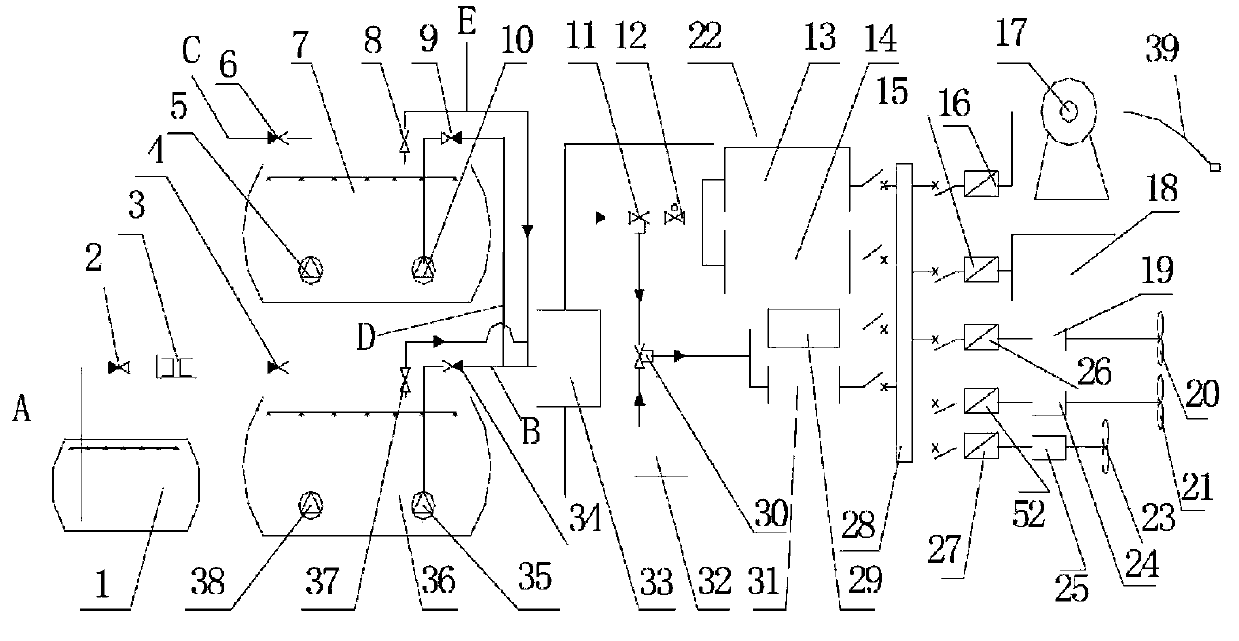

[0021] see figure 1 and figure 2 , figure 1 It is a schematic plan view of the intelligent liquefied natural gas power generation ship of the present invention, figure 2It is a schematic diagram of the structure and pipeline connection relationship of the intelligent liquefied natural gas power generation ship of the present invention. It can be seen from the figure that the intelligent liquefied natural gas power generation ship of the present invention is installed on the ship body 1 with an LNG storage tank 2, an LNG gasification device 3, a gas generator set 4, Gas buffer device 5, central control equipment 6, power distribution and transformation equipment 7, emergency treatment system 8, ship-to-shore connection system 9, loading metering device 10, condenser 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com