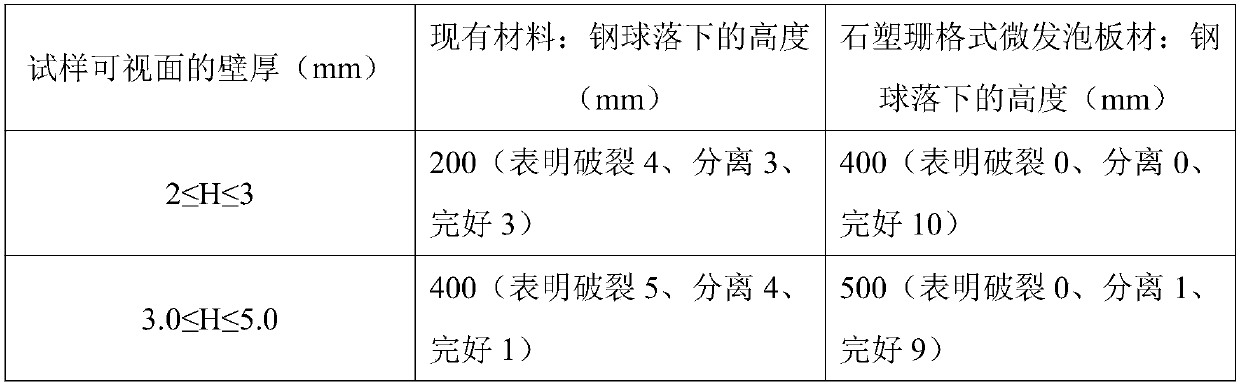

Plastic grid type micro-foamed sheet and its preparation method and application

A foamed sheet and micro-foaming technology, applied in the field of wood-plastic materials and their processing, can solve the problems of damage, low strength, poor material strength and workability, etc., and achieve the effect of reducing costs and solving environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

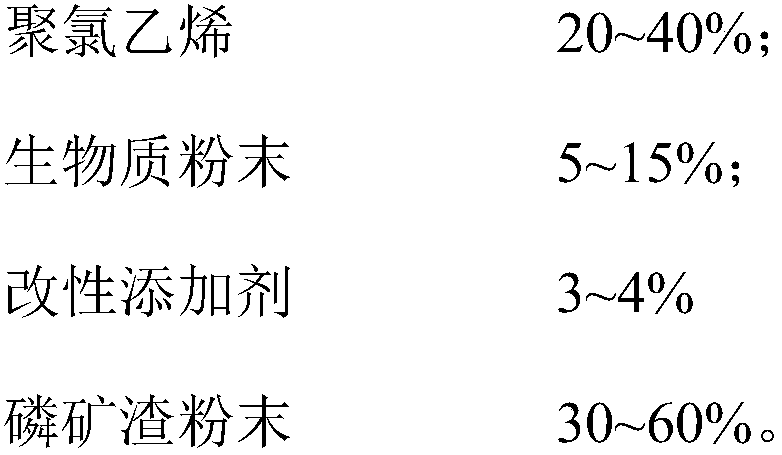

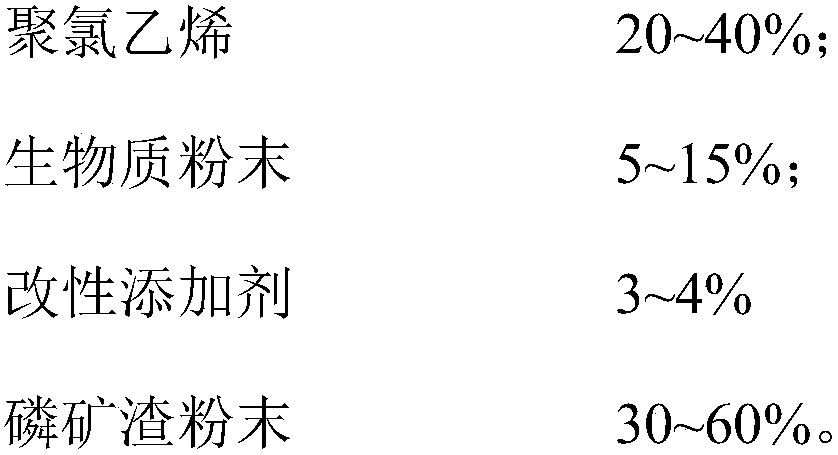

[0030] The composition of the weight of the stone-plastic Shan format micro-foamed plate components described in this embodiment is as follows:

[0031] 20% polyvinyl chloride (PVC); 15% biomass powder; 1.5% polychloride;

[0032] 0.5% stearic acid; 3% paraffin; 60% phosphate slag powder;

[0033] The preparation method of the stone-plastic Shan format micro-foaming plate of above-mentioned components is as follows:

[0034] First, add the above-mentioned precisely measured raw materials and auxiliary materials into the high-temperature tank for mixing and stirring, and unload them into the cooling tank when the temperature of the materials rises to 120°C, and make standby when the temperature reaches 30°C (the standby time should not exceed 4 to 8 hours. ) or sent to the extruder by a screw conveyor, extruded and granulated in the extruder, and the temperature in each section of the barrel in the twin-screw extruder is controlled, specifically: the first section is 150 ° C, ...

Embodiment 2

[0036] The composition of the weight of the stone-plastic Shan format micro-foamed plate components described in this embodiment is as follows:

[0037] 30% polyvinyl chloride (PVC); 5.5% biomass powder; 3% polychloride;

[0038] 1% stearic acid; 3% paraffin; 57.5% phosphate slag powder;

[0039] The preparation method of the stone-plastic Shan format micro-foaming plate of above-mentioned components is as follows:

[0040] First, add the above-mentioned precisely measured raw materials and auxiliary materials into the high-temperature cylinder for mixing and stirring, and unload them into the cooling cylinder when the temperature of the materials rises to 130°C, and make standby when the temperature reaches 35°C (the standby time does not exceed 4 to 8 hours. ) or sent to the extruder by a screw conveyor, extruded and granulated in the extruder, and the temperature in each section of the barrel in the twin-screw extruder is controlled, specifically: the first section is 160 ...

Embodiment 3

[0042] The composition of the weight of the stone-plastic Shan format micro-foamed plate components described in this embodiment is as follows:

[0043] 35% polyvinyl chloride (PVC); 12.5% biomass powder; 4% polychloride;

[0044] 1% stearic acid; 5.5% paraffin; 42% phosphate slag powder;

[0045] The preparation method of the stone-plastic Shan format micro-foaming plate of above-mentioned components is as follows:

[0046] First, add the above-mentioned precisely measured raw materials and auxiliary materials into the high-temperature cylinder for mixing and stirring. When the temperature of the material rises to 137°C, it is unloaded into the cooling cylinder, and when it is cooled to 45°C, it is used for standby (the standby time does not exceed 4 to 8 hours. ) or sent to the extruder by a screw conveyor, extruded and granulated in the extruder, and the temperature in each section of the barrel in the twin-screw extruder is controlled, specifically: the first section is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com