High-performance concrete inner curing material realizing sustained and controlled release of water and preparation method of inner curing material

A technology of high-performance concrete and water release, which is applied in the field of high-performance concrete slow-controlled water-release internal curing materials and its preparation, and concrete internal curing agents, which can solve the problems of difficult control of the water release rate of internal curing materials and reduce the strength of concrete. Achieve the effects of increasing thermal stability and water retention capacity, reducing cracking and improving work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The present embodiment provides a kind of high-performance concrete slow and controlled release water internal curing material, by weight fraction, is made of the following raw materials: 17.5% metakaolin, 12% diatomite, 9% graphene oxide, 7% % silane coupling agent, 3.5% sodium alginate, 5% xanthan gum, 3% slaked lime, 2.74% sodium acetate, 27% sodium acrylate, 12.5% 2-acrylamide-2-methyl Propanesulfonic acid, 0.06% crosslinker, 0.7% initiator.

[0042] In this example:

[0043] The particle size of metakaolin is 1500 mesh, SiO in metakaolin 2 The content is 40% to 60%.

[0044] The particle size of diatomite is 300 mesh, SiO in diatomite 2 The content of Fe is 80% to 90%. 2 o 3 Content≤1.2%.

[0045] The silane coupling agent is 3-aminopropanetriethoxysilane.

[0046] The particle size of slaked lime is 325 mesh, Ca(OH) in slaked lime 2 content ≥ 90%.

[0047] The crosslinker is made of polyvinyl alcohol and glycerin in a 1:1 weight ratio. The polyvinyl al...

Embodiment 2

[0062] This embodiment provides a kind of high-performance concrete slow and controlled release water interior curing material, is made of the following raw materials in terms of weight fraction: 17% metakaolin, 11% diatomite, 9.5% graphene oxide, 7.5% % silane coupling agent, 3.5% sodium alginate, 5.5% xanthan gum, 2.5% hydrated lime, 1.63% sodium acetate, 28% sodium acrylate, 13% 2-acrylamide-2-methyl Propanesulfonic acid, 0.07% crosslinker, 0.8% initiator.

[0063] The kind and consumption requirement of each raw material in the present embodiment are identical with embodiment 1.

[0064] The preparation method of the high-performance concrete slow-controlled release water internal curing material in this embodiment is basically the same as that in Embodiment 1.

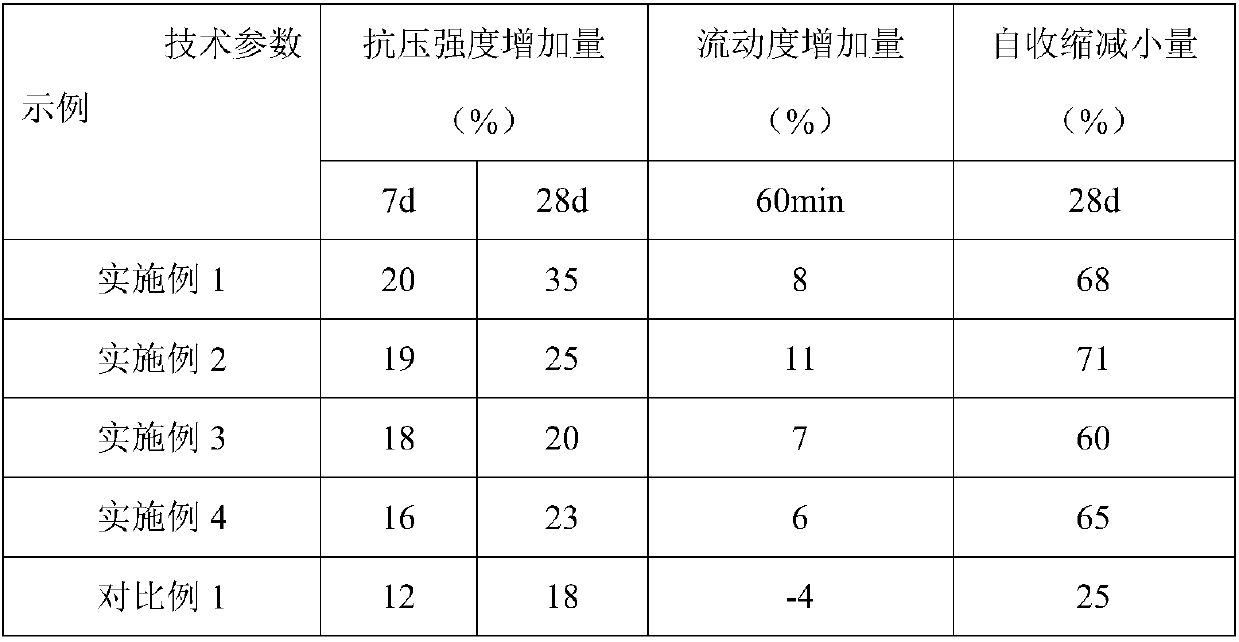

[0065] The performance test process of this embodiment is basically the same as that of Example 1, and the content of the internal curing material is 0.5% of the cement content. The performance test results of th...

Embodiment 3

[0067] This embodiment provides a kind of high-performance concrete slow and controlled release water internal curing material, by weight fraction, made of the following raw materials: 20% metakaolin, 10% diatomite, 8% graphene oxide, 6 % silane coupling agent, 4% sodium alginate, 6% xanthan gum, 4% slaked lime, 0.95% sodium acetate, 30% sodium acrylate, 10% 2-acrylamide-2-methyl Propanesulfonic acid, 0.05% crosslinker, 1% initiator.

[0068] The kind and consumption requirement of each raw material in the present embodiment are identical with embodiment 1.

[0069] The preparation method of the high-performance concrete slow-controlled release water internal curing material in this embodiment is basically the same as that in Embodiment 1.

[0070] The performance test process of this embodiment is basically the same as that of Embodiment 1, and the performance test results of this embodiment are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com