Method for producing functional material by solid waste as well as application

A functional, solid waste technology, applied in the field of building materials, can solve the problems of weak technical force, low market competitiveness, single solid waste treatment technology, etc., to improve core competitiveness, enhance market competitiveness, and achieve significant social benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

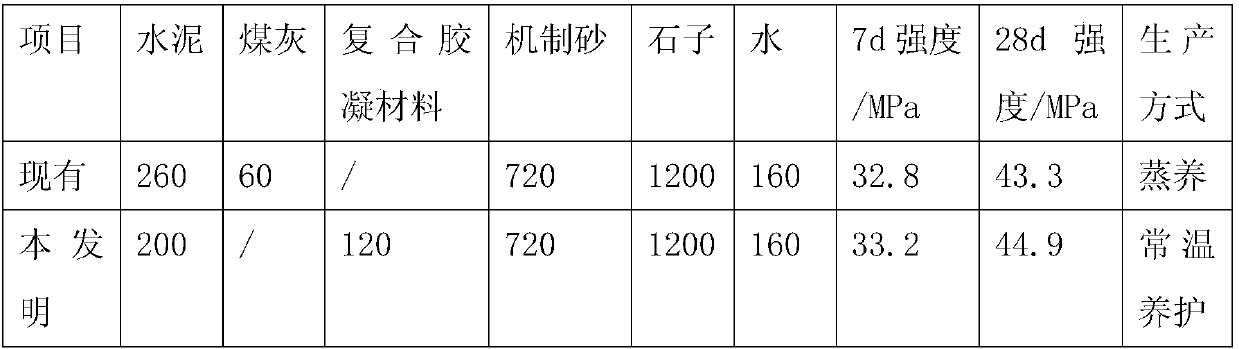

[0034] Embodiment 1. Using solid waste to prepare steam-free concrete

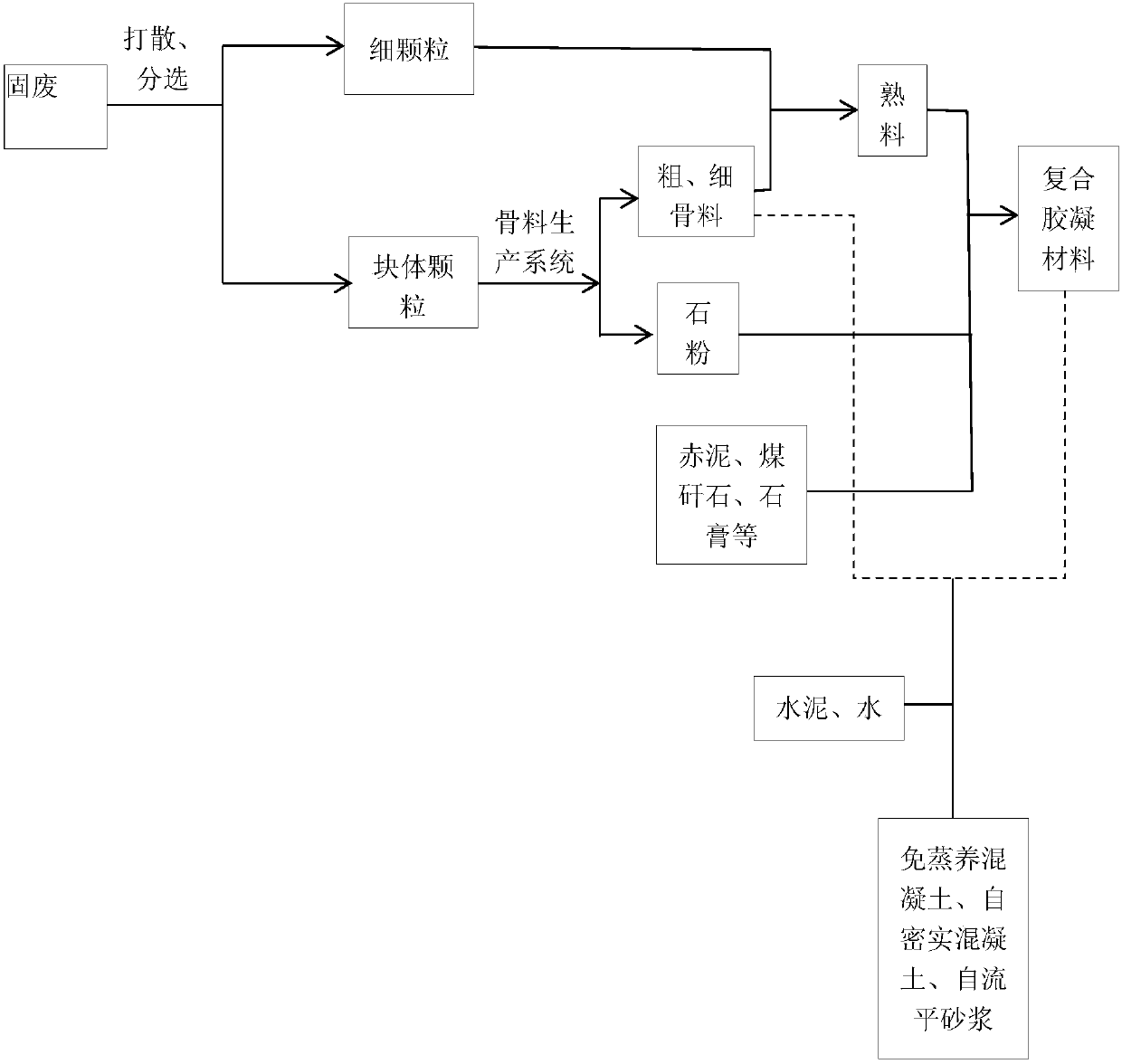

[0035] 1. Solid waste processing to prepare functional materials

[0036] (1) Pretreatment of solid waste: After collecting quarry debris, tailings, tunnel slag, construction waste, etc., they are broken up and sorted into fine particles and massive particles. Specifically, the first is the sorting of color, such as sorting the broken particles of red bricks separately as raw materials for clinker production; Waste materials such as soil contained in the clinker are directly used as raw materials for the production of clinker; ②25mm-100mm blocky particles enter the production system to produce coarse and fine aggregates; ③>100mm particles are returned again for breaking up and sorting again.

[0037] (2) Aggregate production: the massive particles in step (1) are made into coarse and fine aggregates (replacing stones and Machine-made sand); particles with a particle size between 4.75-31.5 mm can be used ...

Embodiment 2

[0069] Embodiment 2. Using solid waste to prepare self-compacting concrete

[0070] 1. Solid waste processing to prepare functional materials

[0071] The processing of solid waste is the same as in Example 1.

[0072] 2. Preparation of self-compacting concrete

[0073] The self-compacting concrete prepared by the inventive method is compared with the existing self-compacting concrete effect as follows:

[0074] The formula of the composite cementitious material of the present invention: 30% of clinker, 10% of red mud, 10% of burnt coal gangue, 40% of stone powder, 10% of gypsum, and 1.5% of powder activator.

[0075] The clinker comes from the preparation of the aforementioned step (3), and the stone powder comes from the collection of the coarse and fine aggregates in the aforementioned step (2).

[0076] In the self-compacting concrete raw material of the present invention, the fine aggregate prepared in step (2) is used to replace machine-made sand, and the coarse aggre...

Embodiment 3

[0081] Example 3: Using solid waste to prepare self-leveling mortar

[0082] 1. Solid waste processing to prepare functional materials

[0083] The processing of solid waste is the same as in Example 1.

[0084] 2. Preparation of self-leveling mortar

[0085] The self-leveling mortar prepared by the method of the present invention is compared with the existing self-leveling mortar effect as follows:

[0086] The formula of the composite cementitious material of the present invention: 10% of clinker, 20% of burnt coal gangue, 20% of red mud, 40% of stone powder, 10% of gypsum, and 1.5% of activator.

[0087] In the self-leveling mortar raw material of the present invention, the fine aggregate prepared in step (2) is used to replace machine-made sand.

[0088] The DM10 self-leveling mortar prepared by the method of the present invention is compared with the existing ones, and the results are shown in Table 5:

[0089] table 5

[0090] project

[0091] Conclusion: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com