A kind of preparation method of side chain modified block silicone oil

A block silicone oil, modification technology, applied in the direction of improved hand feeling fiber, textiles and papermaking, fiber treatment, etc., can solve the problem of poor stability, linear ternary copolymerization block silicone oil can not achieve the soft effect of amino silicone oil, affect the silicone chain To solve problems such as segment smoothing effect, achieve good stability, solve poor hand feeling, and solve the effect of demulsification of amino silicon, which is easy to float and oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Mix 100kg of single-end hydrogen-containing silicone oil and 19kg of allyl polyoxyalkylene epoxy ether in 51kg of isopropanol solution evenly, add 0.4kg of chloroplatinic acid catalyst at 75°C, control the reaction temperature at 75°C, and react 4h, slough isopropanol to obtain single-end epoxy silicone oil;

[0032] Under the protection of nitrogen, raise the temperature of the mixture of 31kg isopropanol and 5kg diethylenetriamine to 80°C, slowly add 115kg single-end epoxy silicone oil dropwise, control the dropping time at 1h, continue to react for 2h after the dropping is completed, and remove the isopropyl alcohol. propanol, intermediate I is obtained;

[0033] Add 100kg of double-ended epoxy silicone oil into 84kg of isopropanol, then add 13kg of intermediate I, heat to 85°C, react for 8 hours, remove isopropanol, and obtain side chain modified block silicone oil;

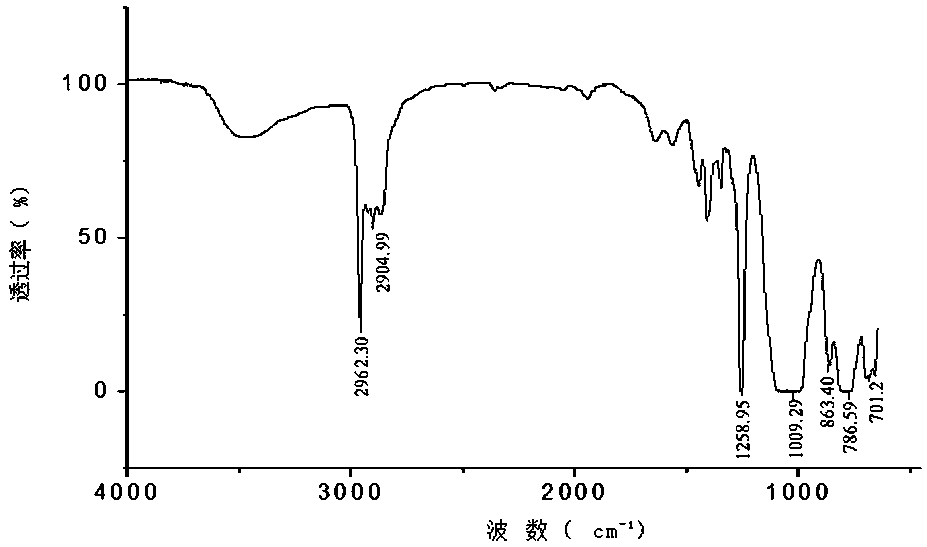

[0034] from figure 1 It can be seen that the stretching vibration peak of the Si-O bond is at the...

Embodiment 2

[0047] Mix 100kg of single-end hydrogen-containing silicone oil and 18kg of allyl polyoxyalkylene epoxy ether in 50kg of isopropanol solution evenly, add 0.38kg of chloroplatinic acid catalyst at 70°C, control the reaction temperature at 75°C, and react 3h, slough isopropanol to obtain single-end epoxy silicone oil;

[0048] Under the protection of nitrogen, raise the temperature of the mixture of 30kg isopropanol and 5kg diethylenetriamine to 80°C, slowly add 114kg single-end epoxy silicone oil dropwise, control the dropping time at 0.75h, continue to react for 2h after the dropping is completed, and remove Virahol, obtain intermediate I;

[0049] Add 100kg of double-ended epoxy silicone oil to 82kg of isopropanol, then add 12kg of intermediate I, heat to 80°C, react for 8 hours, remove isopropanol, and obtain side chain modified block silicone oil.

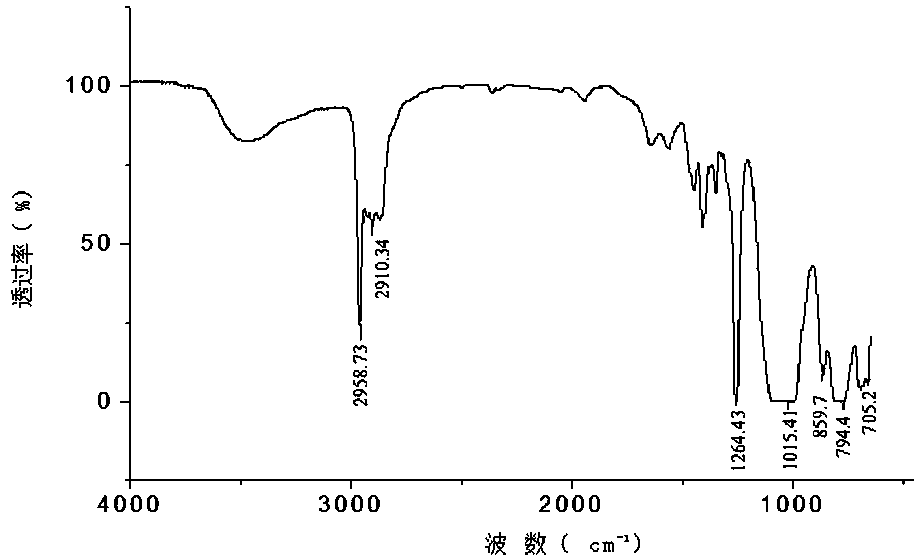

[0050] from figure 2 It can be seen that, at the wave number of 1015.41cm -1 The stretching vibration peak of the Si-O bon...

Embodiment 3

[0063] Mix 100kg of single-end hydrogen-containing silicone oil and 17kg of allyl polyoxyalkylene epoxy ether in 50kg of isopropanol solution evenly, add 0.35kg of chloroplatinic acid catalyst at 70°C, control the reaction temperature at 70°C, and react 3h, slough isopropanol to obtain single-end epoxy silicone oil;

[0064] Under the protection of nitrogen, raise the temperature of the mixture of 29kg isopropanol and 5kg diethylenetriamine to 75°C, slowly add 113kg single-end epoxy silicone oil dropwise, control the dropping time at 0.5h, continue to react for 1h after the dropping is completed, and remove Virahol, obtain intermediate I;

[0065] Add 100kg of double-ended epoxy silicone oil to 82kg of isopropanol, then add 12kg of intermediate I, heat to 80°C, react for 7 hours, remove isopropanol, and obtain side chain modified block silicone oil;

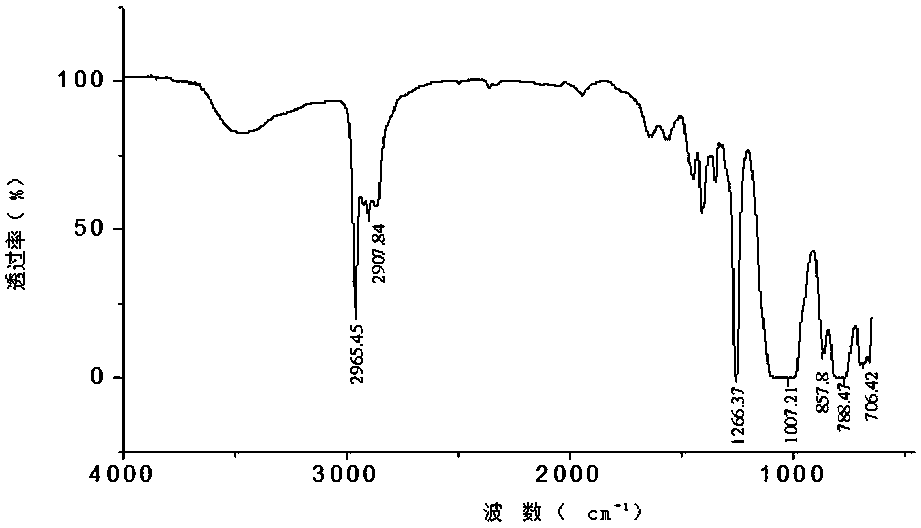

[0066] from image 3 It can be seen from the figure that the wavenumber is 1007.21cm -1 The stretching vibration peak of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com