Lubricating grease and its preparation method

A technology of lubricating grease and matrix, which is applied in the field of lubricating grease and its preparation, and can solve the problems of poor anti-wear performance, strong irritation, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

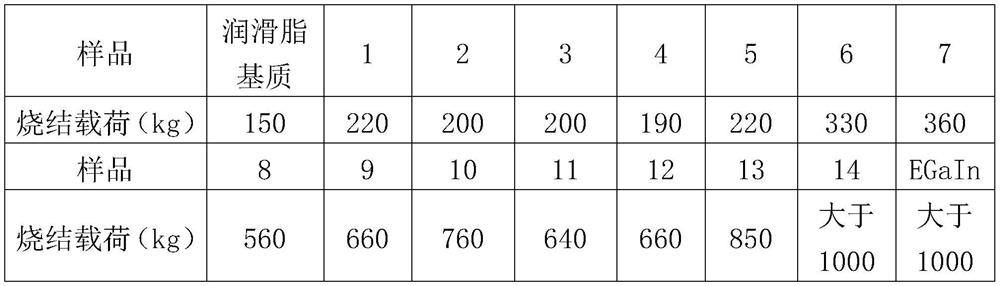

Examples

Embodiment 1

[0042] Take 98g of grease base, add 0.5g of antioxidant 2,6-di-tert-butyl-p-cresol, 1g of anti-wear agent diethyl phosphate amine salt, 0.5g of pure gallium, heat to 90°C and stir for 30min until uniform, cool to room temperature, transferred to a three-roll mill and ground for 3-5 hours to obtain sample 1.

Embodiment 2

[0044] Take 98g of grease matrix, add 0.5g of antioxidant 2,6-di-tert-butyl-p-cresol, 1g of anti-wear agent diethyl phosphate amine salt, 0.5g of a mixture containing 75 parts by weight of gallium and 25 parts by weight of indium, Heat to 90°C and stir for 30min until uniform, transfer to a three-roll mill and grind for 3-5h uniformly, cool to room temperature to obtain sample 2.

Embodiment 3

[0046] Take 98g of grease base, add 0.5g of antioxidant 2,6-di-tert-butyl-p-cresol, 1g of anti-wear agent diethyl phosphate amine salt, containing 64 parts by weight of gallium, 24 parts by weight of indium and 12 parts by weight of tin 0.5 g of the mixture was heated to 90°C and stirred for 30 min until uniform, cooled to room temperature, transferred to a three-roll mill and ground for 3-5 h to obtain sample 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com