Method for improving pitting corrosion resistance and strength of stainless steel

A stainless steel, corrosive technology, applied in the field of improving corrosion resistance and mechanical properties, improving pitting corrosion resistance and strength of 304 stainless steel, can solve undiscovered problems, achieve reduction of alloying cost, simple operation, and increase tensile strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

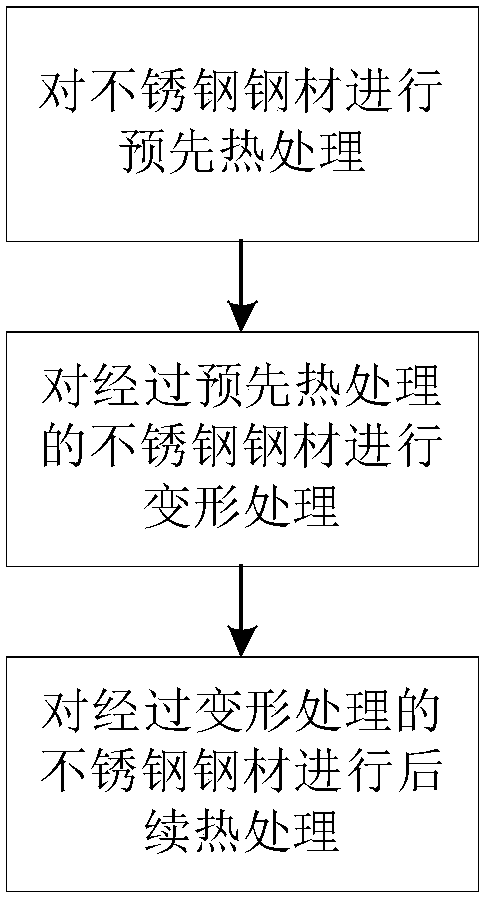

Method used

Image

Examples

Embodiment 1

[0040] Pre-heat treatment process:

[0041] (1) Heat the temperature of the air furnace to 1050°C;

[0042] (2) Put in the steel, close the furnace door and keep warm for 30 minutes;

[0043] (3) Open the furnace door, take out the steel and water quench, and the material transfer time is 2s.

[0044] Deformation process:

[0045] (1) Under room temperature, the pre-heat-treated steel is compressed to produce a small deformation of 5%;

[0046] (2) The strain rate is 0.02s -1 .

[0047] Subsequent heat treatment process:

[0048] (1) Put the deformed steel into an air furnace whose temperature has reached 1050°C for 20 minutes;

[0049] (2) Water quenching after taking out, material transfer time 2s.

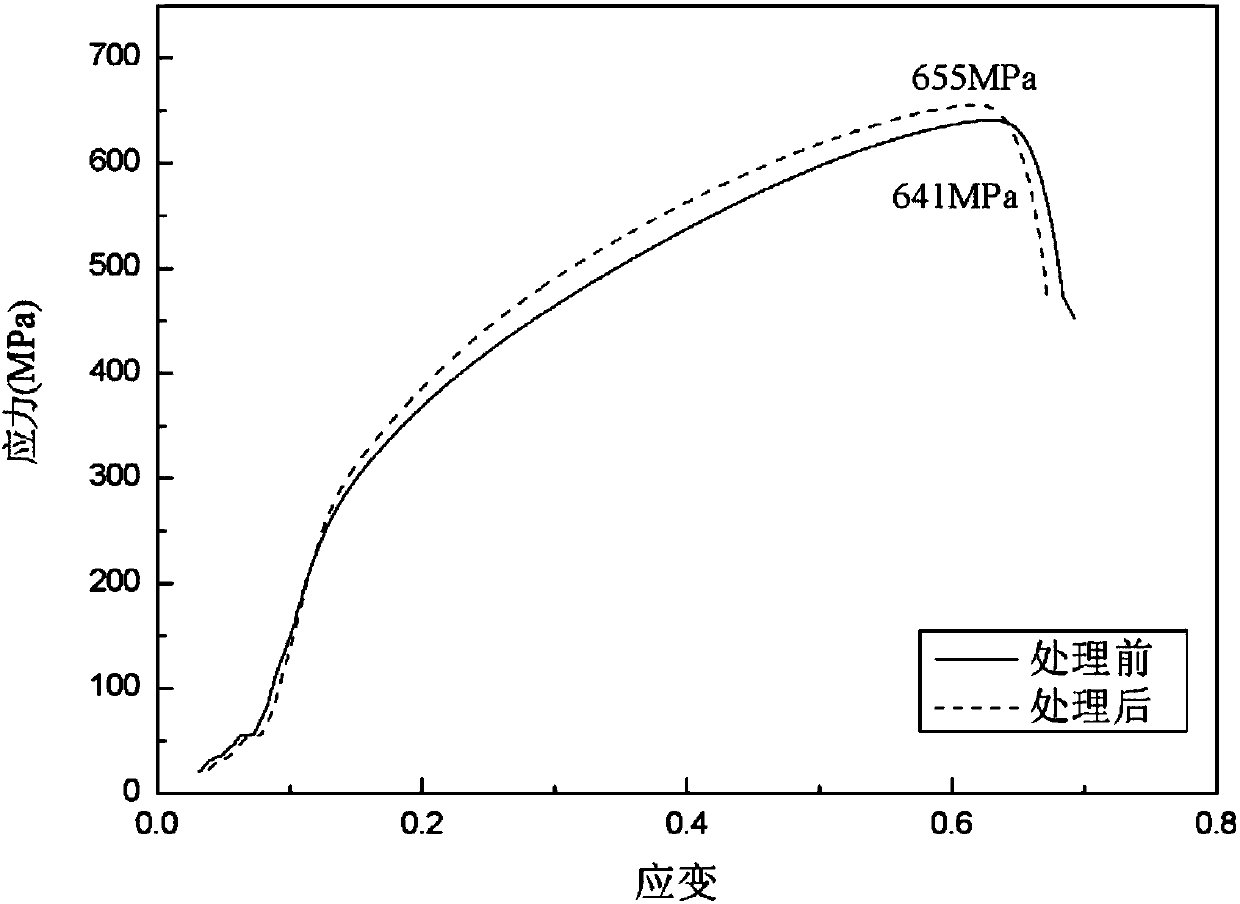

[0050] Compared with the untreated sample, the mechanical properties of the obtained 304 stainless steel are as follows: figure 1 As shown, the tensile strength increased from 641MPa to 655MPa, an increase of about 2.2%. The pitting corrosion rate is changed from 2.39g / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com