Preparation method of cationic polyester tricolor polyester filament

A technology of polyester filament and Diyang, which is applied in the field of preparation of Diyang three-color polyester filament, can solve the problems of high cost, complicated preparation process, unfavorable large-scale mass production, etc., and achieve the effect of soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of polyester-yang tricolor polyester filament, comprising the following steps:

[0033] Polyester bright semi-oriented silk MOY is produced by spinning, with a specification of 130dtex / 48f, a strength of 1.8cn / dtex, and an elongation of 160%. Cationic FDY specifications are 55dtex / 48f, a strength of 3.0cn / dtex, and an elongation of 20%.

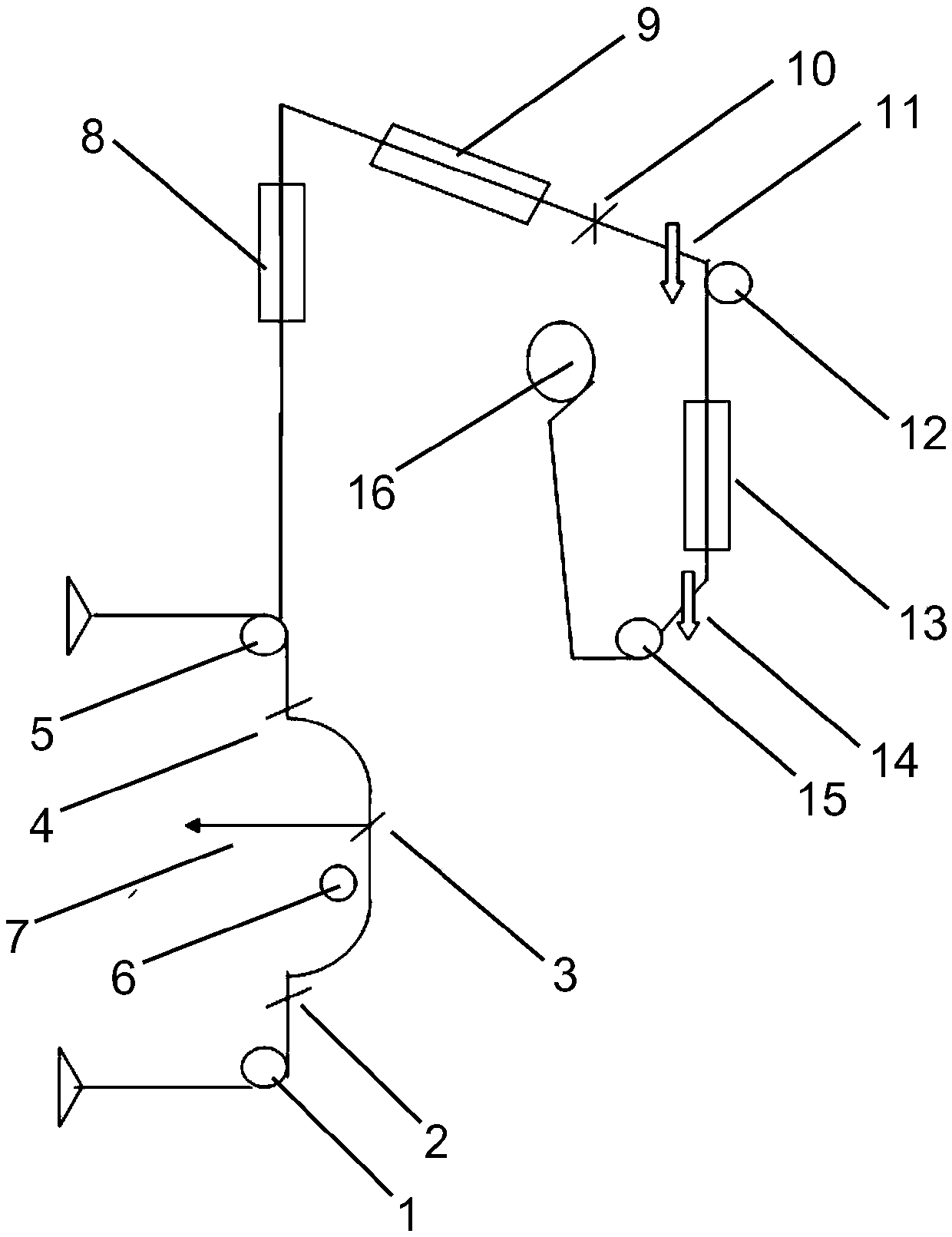

[0034] Such as figure 1 As shown, the polyester bright semi-oriented yarn MOY is successively transmitted to the first roller 5 through the zero roller 1, the first yarn guide 2, the second yarn guide 3 and the third yarn guide 4; wherein, in the first A heat roller 6 is arranged between the yarn guide and the second yarn guide, and a reciprocating pull rod 7 is installed on the second yarn guide, and the reciprocating pull rod can drive the second yarn guide to swing back and forth along the direction perpendicular to the silk path, so as to The polyester bright semi-oriented yarn MOY is intermittently heated by ...

Embodiment 2

[0041] A preparation method of polyester-yang tricolor polyester filament, comprising the following steps:

[0042] Polyester semi-oriented yarn MOY is obtained by spinning, with a specification of 220dtex / 72f, a strength of 1.85cn / dtex, and an elongation of 165%, and a cationic FDY specification of 83dtex / 72f, with a strength of 3.1cn / dtex, and an elongation of 22%.

[0043]The polyester bright semi-oriented yarn MOY is transmitted to the first roller 5 through the zero roller 1, the first yarn guide 2, the second yarn guide 3 and the third yarn guide 4 in sequence; A hot roller 6 is arranged between the second yarn guide and a reciprocating pull rod 7 is installed on the second yarn guide. The reciprocating pull rod can drive the second yarn guide to swing back and forth along the direction perpendicular to the silk path, so that the polyester The bright semi-oriented yarn MOY is intermittently heated by hot rollers.

[0044] Cationic FDY is compounded with polyester bright...

Embodiment 3

[0048] A preparation method of polyester-yang tricolor polyester filament, comprising the following steps:

[0049] Polyester semi-oriented silk MOY is produced by spinning, with a specification of 305dtex / 96f, a strength of 1.8cn / dtex, and an elongation of 170%, and a cationic FDY specification of 111dtex / 72f, with a strength of 3.0cn / dtex, and an elongation of 20%.

[0050] The polyester bright semi-oriented yarn MOY is transmitted to the first roller 5 through the zero roller 1, the first yarn guide 2, the second yarn guide 3 and the third yarn guide 4 in sequence; A hot roller 6 is arranged between the second yarn guide and a reciprocating pull rod 7 is installed on the second yarn guide. The reciprocating pull rod can drive the second yarn guide to swing back and forth along the direction perpendicular to the silk path, so that the polyester The bright semi-oriented yarn MOY is intermittently heated by hot rollers.

[0051] Cationic FDY is compounded with polyester brigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com