Efficient drying conveying belt

A conveyor belt and drying technology, applied in the field of conveyor belts, can solve problems such as low drying efficiency and waste heat, and achieve the effects of easy removal and cleaning, energy saving and production environment improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

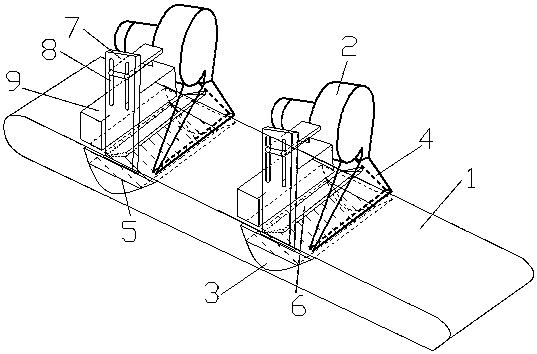

[0017] The high-efficiency drying conveyor belt includes a conveyor belt 1 driven by a motor, a hot air blower 2, and an air source heat pump 9. The conveyor belt 1 is a mesh belt with holes. Above the conveyor belt 1, a U-shaped groove 3 is arranged on the body below the uplink surface of the conveyor belt 1. Corresponding to the side, the air inlet of the hot air blower 2 is provided with a condenser, and the condenser is connected with the air energy heat pump 9 .

[0018] The object is transported on the conveyor belt, and the hot air generated by the hot air blower is blown downward from the air outlet to dry the upper surface of the object, and then passes through the hole on the conveyor belt 1, enters the U-shaped groove from the side of the U-shaped groove, and passes through the U-shaped groove. Under the guidance of the guide, it blows upward from the other side of the U-shaped groove to dry the bottom surface of the object, making the drying more uniform and more e...

Embodiment 2

[0020] The high-efficiency drying conveyor belt includes a conveyor belt 1 driven by a motor, a hot air blower 2, and an air source heat pump 9. The conveyor belt 1 is a mesh belt with holes. Above the conveyor belt 1, a U-shaped groove 3 is arranged on the body below the uplink surface of the conveyor belt 1. Corresponding to the side, the air inlet of the hot air blower 2 is provided with a condenser, and the condenser is connected with the air energy heat pump 9 . The two ends of the U-shaped groove 3 are opened, and a slide rail is arranged in the U-shaped groove 3. The slide rail is from one end of the U-shaped groove 3 to the other end of the U-shaped groove 3. The oil filter 5 is arranged through the slide rail in the U-shaped groove 3 to prevent oil pollution. The surface of filter screen 5 is wrapped with oil-absorbing felt. Prevent the oil stain of the dry matter from dripping in the U-shaped groove 3, and the setting of the slide rail is convenient for the oil filt...

Embodiment 3

[0023] The high-efficiency drying conveyor belt includes a conveyor belt 1 driven by a motor, a hot air blower 2, and an air source heat pump 9. The conveyor belt 1 is a mesh belt with holes. Above the conveyor belt 1, a U-shaped groove 3 is arranged on the body below the uplink surface of the conveyor belt 1. Corresponding to the side, the air inlet of the hot air blower 2 is provided with a condenser, and the condenser is connected with the air energy heat pump 9 . A moisture absorber is arranged in the hot air blower 2 near the air inlet. There is water vapor in the air, especially after the object is dried, there will be more water vapor in the air. The moisture absorber absorbs the water vapor and then blows it out after being heated by the hot air blower to ensure the drying efficiency. The two ends of the U-shaped groove 3 are opened, and a slide rail is arranged in the U-shaped groove 3. The slide rail is from one end of the U-shaped groove 3 to the other end of the U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com