Temperature transmission device and method based on program-controlled dual constant current power supply

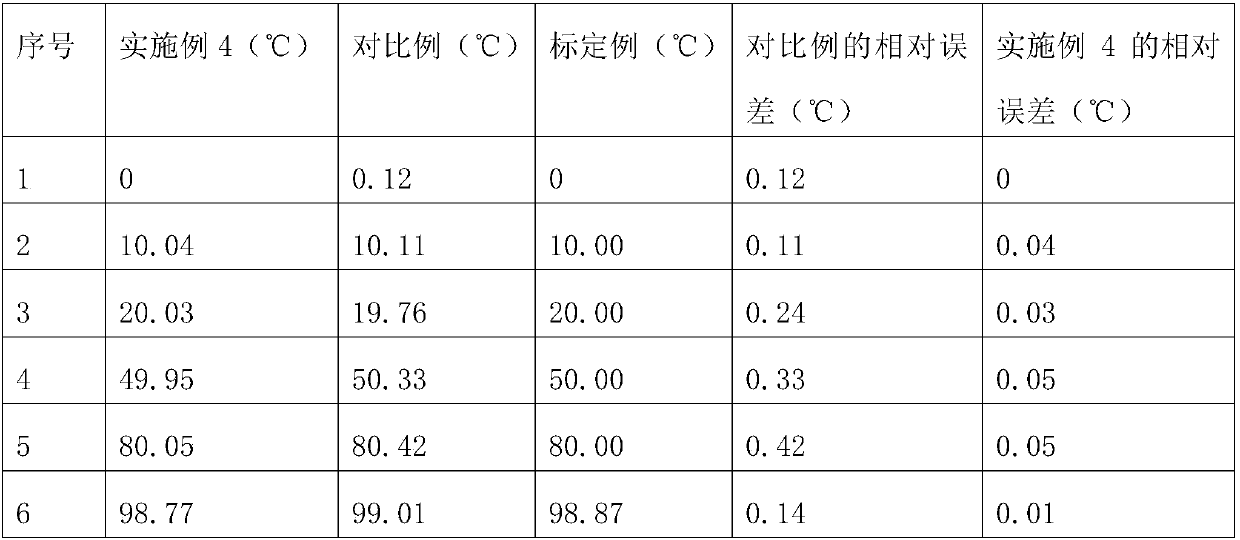

A technology of constant current power supply and constant current source, which is applied to thermometers and thermometers using electric devices and electric/magnetic components that are directly sensitive to heat. It can solve the problem that the circuit output is not 0 and the absolute accuracy cannot reach ±0.1°C And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

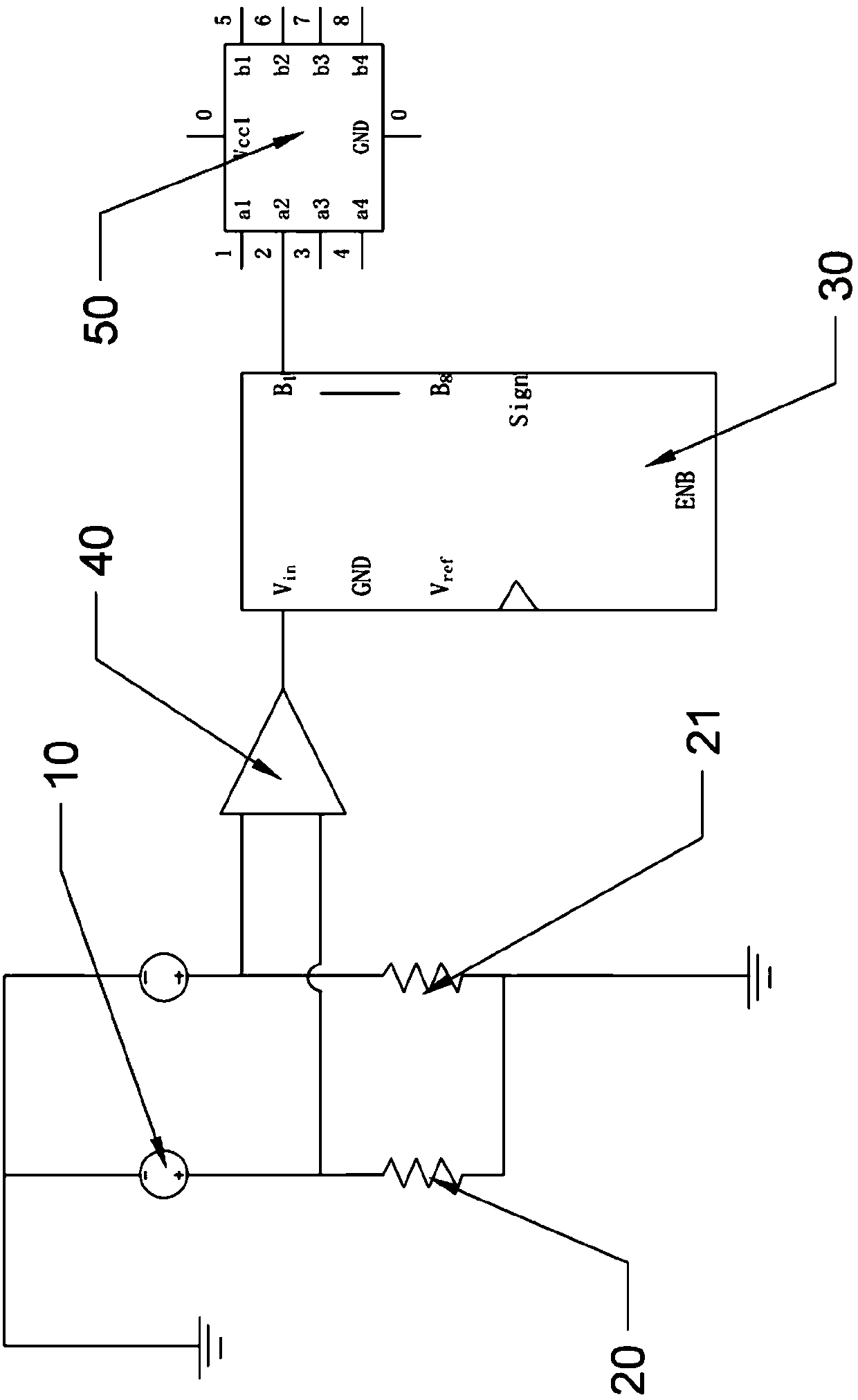

[0048] figure 1 The reference signs in include: constant current source 10 , thermal resistance 20 , reference resistance 21 , A / D converter 30 , differential amplifier 40 , and microprocessor 50 .

[0049] Basic as attached figure 1 Shown: A temperature transmitter based on a programmable dual constant current power supply, including:

[0050] Thermal resistance 20, the resistance value of described thermal resistance 20 can increase as temperature rises, and concrete thermal resistance 20 is Pt100 thermal resistance 20;

[0051] Reference resistor 21, the reference resistor 21 has the same resistance value as the thermal resistor 20 at 0°C, and the specific reference resistor 21 is a high-precision resistor produced by Zhongshan Xinchiyu Electronic Development Co., Ltd., with a resistance value of 100Ω;

[0052] Two constant current sources 10, the currents generated by the two constant current sources 10 are the same, the currents generated by the two constant current sou...

Embodiment 2

[0061] Compared with Embodiment 1, the only difference is that the A / D converter is provided in the microprocessor. That is to say, what the microprocessor chooses is a high-speed single-chip microcomputer with its own A / D conversion function.

Embodiment 3

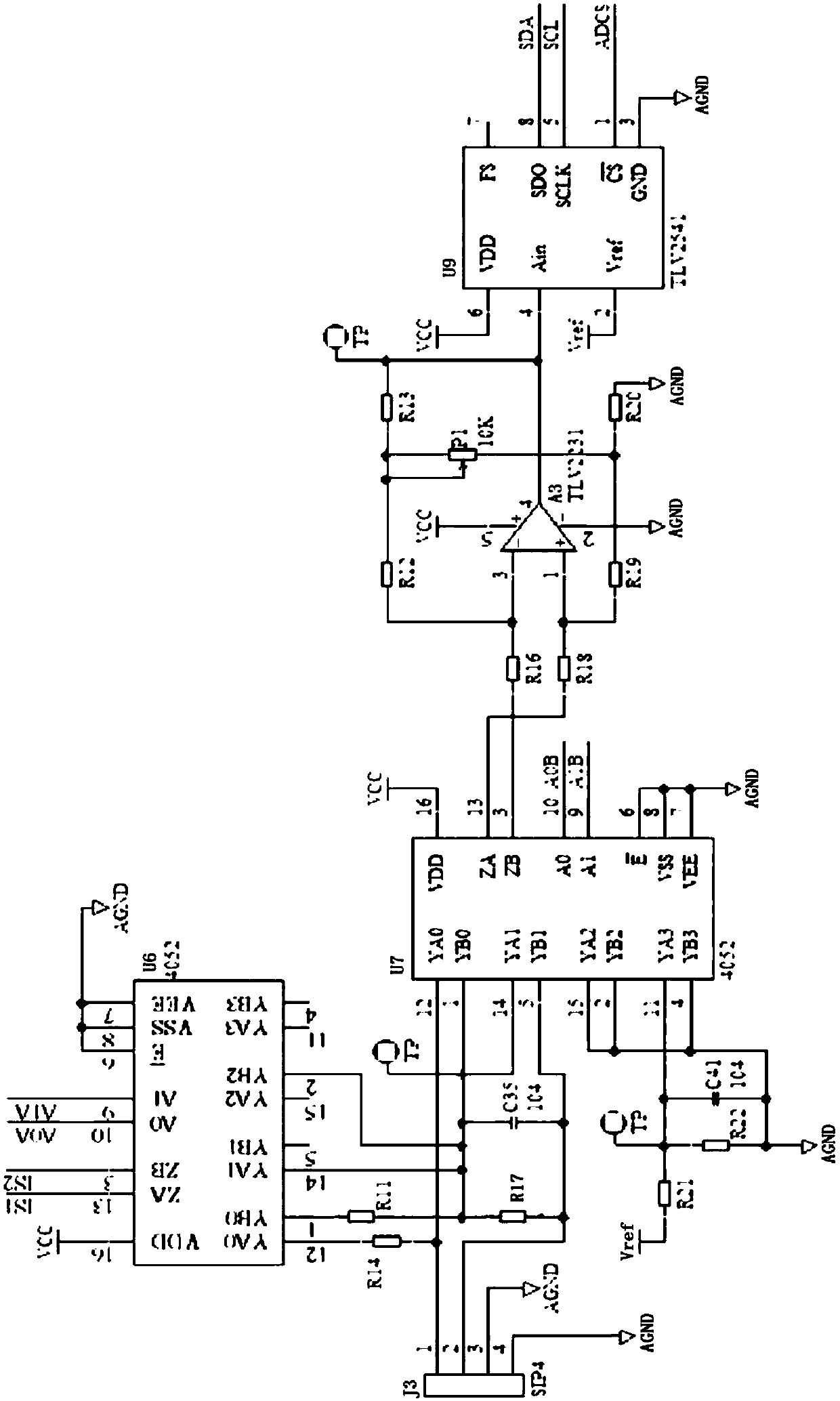

[0063] Compared with Embodiment 1, the only difference is that a second multiplexer is also included, and the second multiplexer is used to switch the load status of the two constant current sources, and the load status of the two constant current sources can be given by A bridge formed by a thermal resistor and a reference resistor, or two constant current sources flow through the reference resistor respectively, the second multiplexer is connected to the microprocessor signal, and the A / D converter is also used to read the voltage on the reference resistor And fed back to the microprocessor, the microprocessor adjusts the currents output by the two constant current sources respectively according to the feedback from the A / D converter.

[0064] In specific use: the microprocessor controls one of the two constant current sources to start, and then the microcontroller controls the second multiplexer, so that the load of the started constant current source is the reference resist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com