Anti-decomposable corrosion hydraulic concrete mixed proportion design method

A hydraulic concrete and mix ratio design technology, which is applied in the analysis of materials, strength characteristics, weather resistance/light resistance/corrosion resistance, etc., can solve the problems of no clear analysis of the impact of concrete's resistance to decomposition and corrosion, and achieve excellent performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment provides a method for designing the mix ratio of anti-decomposition erosion hydraulic concrete, including the following steps:

[0026] Step 1) Take the five factors of cement type, water reducing agent type, air-entraining agent type, admixture dosage, and water-binder ratio as the investigation objects of the orthogonal test, and conduct the orthogonal test;

[0027] Step 2) According to the orthogonal table design in the orthogonal test, the concrete is formed according to each proportion, and the slump is controlled at 50~90. Mortar specimens with the same shape and volume should be cured in static water at 20°C after hardening;

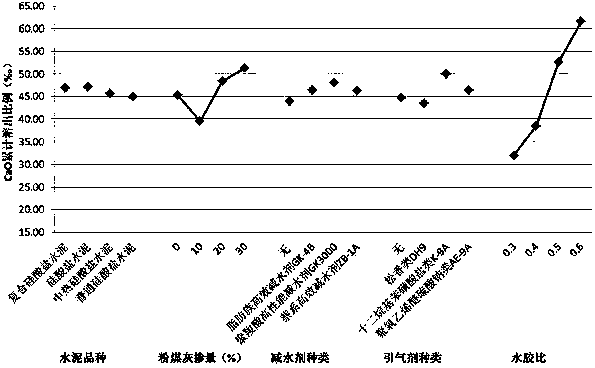

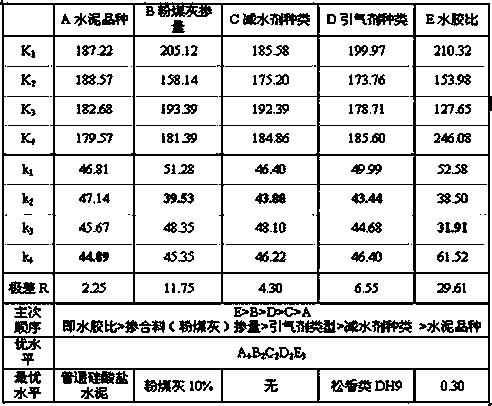

[0028] Step 3) Put the proportioned mortar specimens after curing for the same time into CO2 at a constant speed. 2 The erosion test was carried out in the water, and after the erosion lasted for 80-100 days, the cumulative dissolution ratio of CaO in the erosion age process of each group of test pieces was calculated, and...

Embodiment 2

[0033] On the basis of Example 1, this example takes the anti-decomposition erosion concrete of design grade C30 as an example, and proceeds to the concrete mix design according to the following steps:

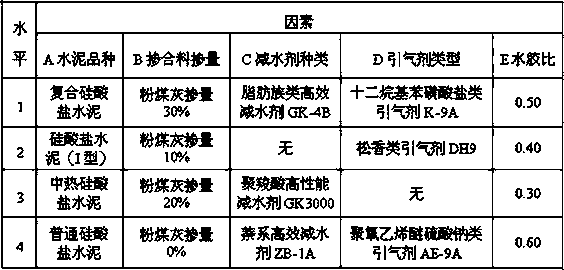

[0034] Step 1) Study the four types of cement used in a certain project (composite Portland cement, Portland cement, medium heat Portland cement, ordinary Portland cement), four fly ash content (0% , 10%, 20%, 30%), three types of water reducing agents (polycarboxylate high-performance water reducing agents, naphthalene-based high-efficiency air-entraining agent, dodecylbenzene sulfonate air-entraining agent, polyoxyethylene ether sodium sulfate air-entraining agent) and four water-binder ratios (0.30, 0.40, 0.50, 0.60) for the corrosion resistance of the decomposition of concrete Influence, the design orthogonal table is shown in Table 1.

[0035] Table 1 Instance 2 Orthogonal table design

[0036]

[0037] Step 2) According to the orthogonal table design table 1, form t...

Embodiment 3

[0070] In this embodiment, taking the anti-decomposition erosion concrete of the design grade C25 as an example, the concrete mix ratio design is carried out in accordance with the following steps:

[0071] Step 1)-step 3) is the same as embodiment 2;

[0072] Step 4) Concrete preparation strength: refer to Example 2, the concrete preparation strength table is shown in Table 11, and the strength curve test results are the same as Table 8 in Example 2.

[0073] Table 11 Concrete preparation strength table

[0074]

[0075] Preliminary mix ratio: the water-binder ratio and the selected strength curve fitting formula of fly ash content are calculated, and the water-binder ratio of each level of concrete is preliminarily selected. The main parameters of the primary mix ratio determined from this are shown in Table 12 and Table 13.

[0076] Table 12 Primary selection mix ratio

[0077]

[0078] Table 13 Amount of Concrete Materials

[0079]

[0080] Step 5) Review and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com