Adhesive resin composition for toner and manufacturing method of adhesive resin composition

A technology for bonding resins and compositions, which is applied in the directions of developer, electrography, optics, etc., and can solve the problems of uneven resin quality, low viscosity, difficulty in uniform dispersion, and small amount of diisocyanate used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example

[0084] The raw materials adopted in the synthetic examples and their code names are described as follows:

[0085] EG, ethylene glycol.

[0086] DEG, diethylene glycol.

[0087] MPD, 2-methyl-1,3-propanediol.

[0088] NPG, 2,2-dimethyl-1,3-propanediol.

[0089] HPHP, 3-Hydroxy-2,2-dimethyl-3'-hydroxy-2',2'-dimethylpropylpropionate.

[0090] PO-BPA, 2,2-bis[4-(2-hydroxypropoxy)phenyl]propane.

[0091] TMP, 1,1,1-trimethylolpropane.

[0092] PTA, 1,4-phthalic acid.

[0093] IPA, 1,3-phthalic acid.

[0094] HAD, 1,6-Hexanedioic acid.

[0095] MeHHPA, 4-methyl-1,2-cyclohexanedicarboxylic anhydride.

[0096] TMA, 1,2,4-benzenetricarboxylic anhydride.

[0097] PET, polyethylene terephthalate, recycled polyester chips.

[0098] FC-4100, catalyst monobutyltin oxide.

[0099] Synthesis example of polyester resin A

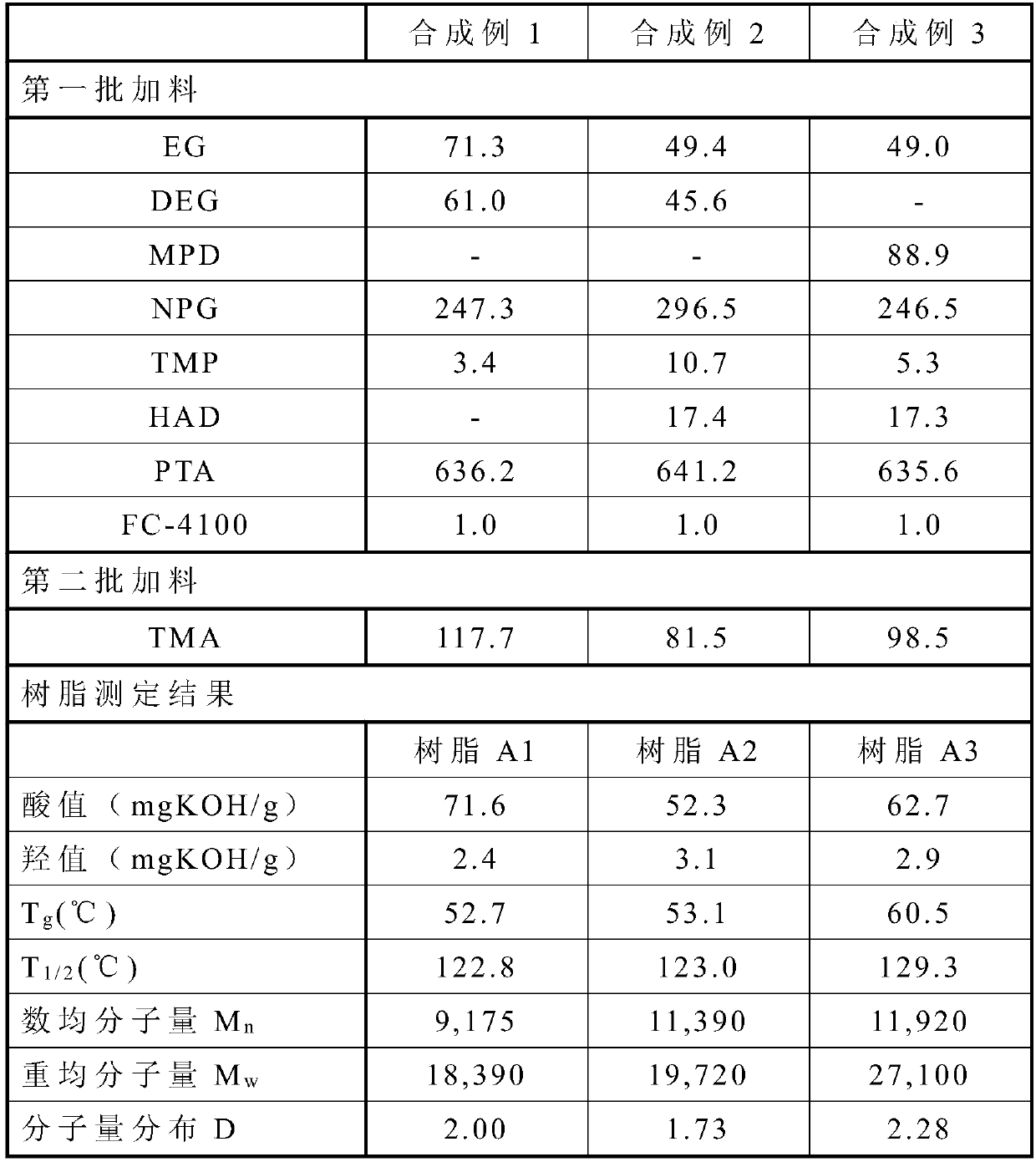

Synthetic example 1

[0100] Synthesis example 1, the synthesis of polyester resin A1

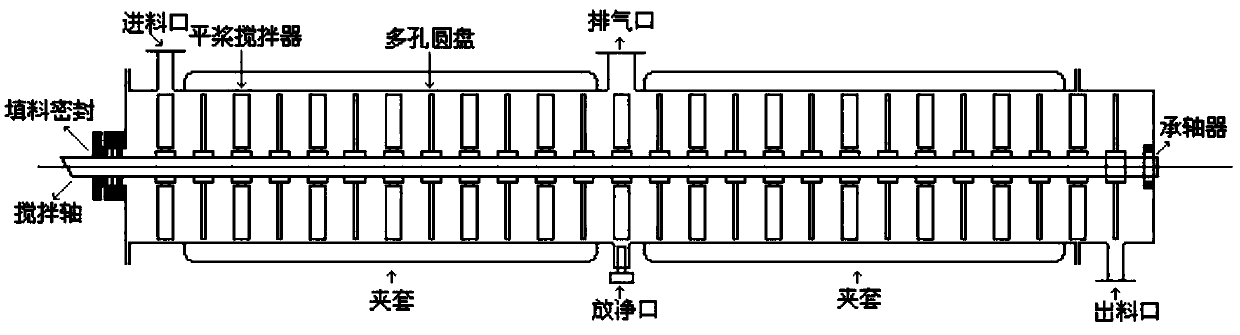

[0101]Add 71.3 parts of ethylene glycol, 61.0 parts of diethylene glycol, and 3.4 parts of 1,1,1-trimethylolpropane to the polymerization reactor equipped with agitator, fractionation column, condenser, reflux device and thermometer, Start the stirrer and heat up to 120°C. Add 247.3 parts of 2,2-dimethyl-1,3-propanediol and continue heating until all is melted. Add 636.2 parts of 1,4-phthalic acid and 1 part of monobutyltin oxide catalyst, and continue to raise the temperature to start the esterification and polycondensation reaction. During the reaction process, pay attention to controlling the distillation rate and reflux rate of the by-product water of the esterification and polycondensation reaction, so as to ensure that the temperature at the top of the fractionation column does not exceed 101°C. The temperature of the reaction material continued to rise to 250° C. and maintained, and the esterification a...

Synthetic example 2~3

[0103] Synthesis Examples 2-3, Synthesis of Polyester Resins A2-A3

[0104] Synthesis Examples 2-3 were prepared according to the ratios of the reaction raw materials listed in columns 3-4 in Table 1, and respectively synthesized carboxyl-type saturated polyester resins A2-A3 according to the method of Synthesis Example 1. Its physical and chemical properties are also listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com