Microwave high-power synthesizer

A high-power, combiner technology, used in waveguide-type devices, electrical components, connecting devices, etc., can solve the problems of limited power tolerance, reduced reliability, large size, etc., and achieve the effect of low cost and simple composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

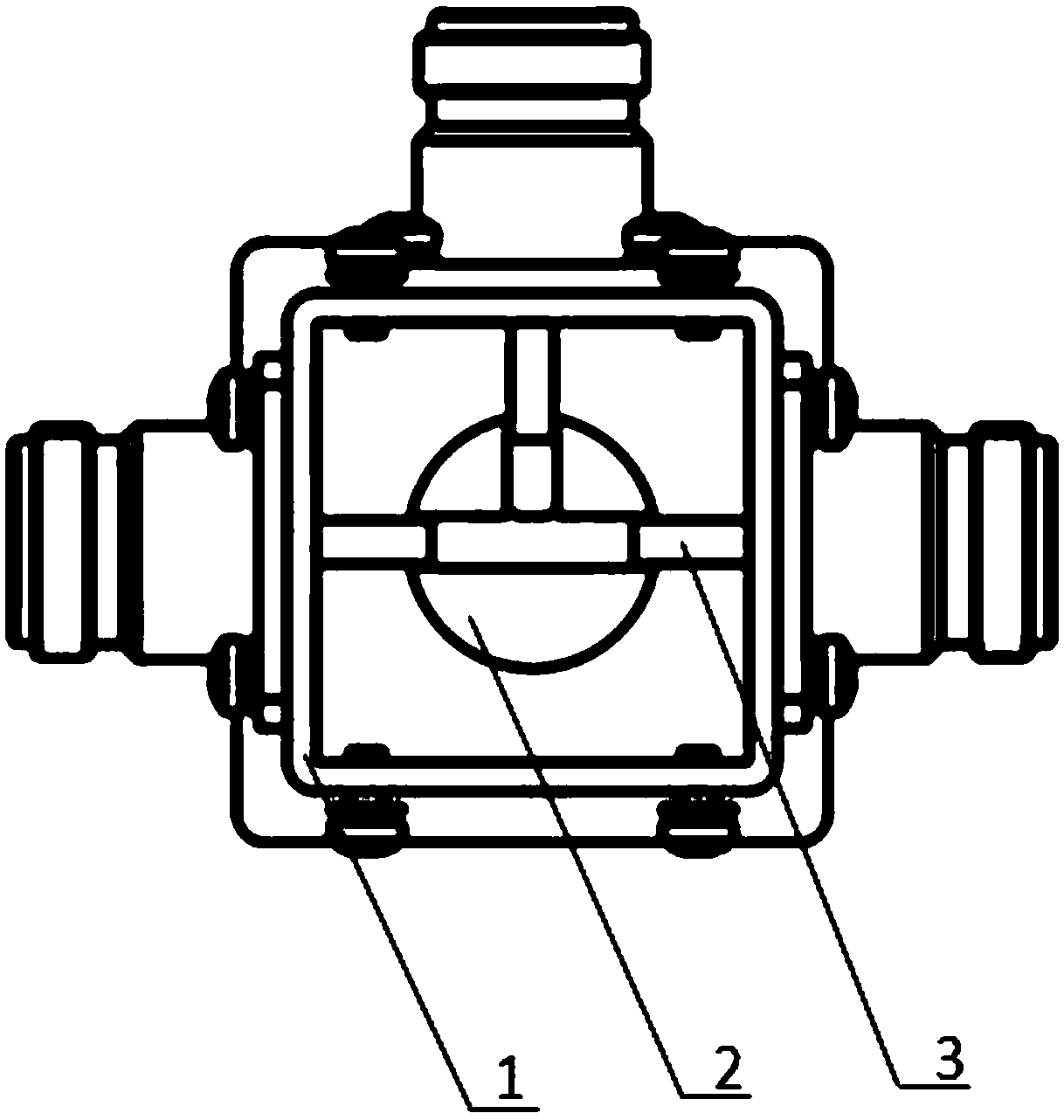

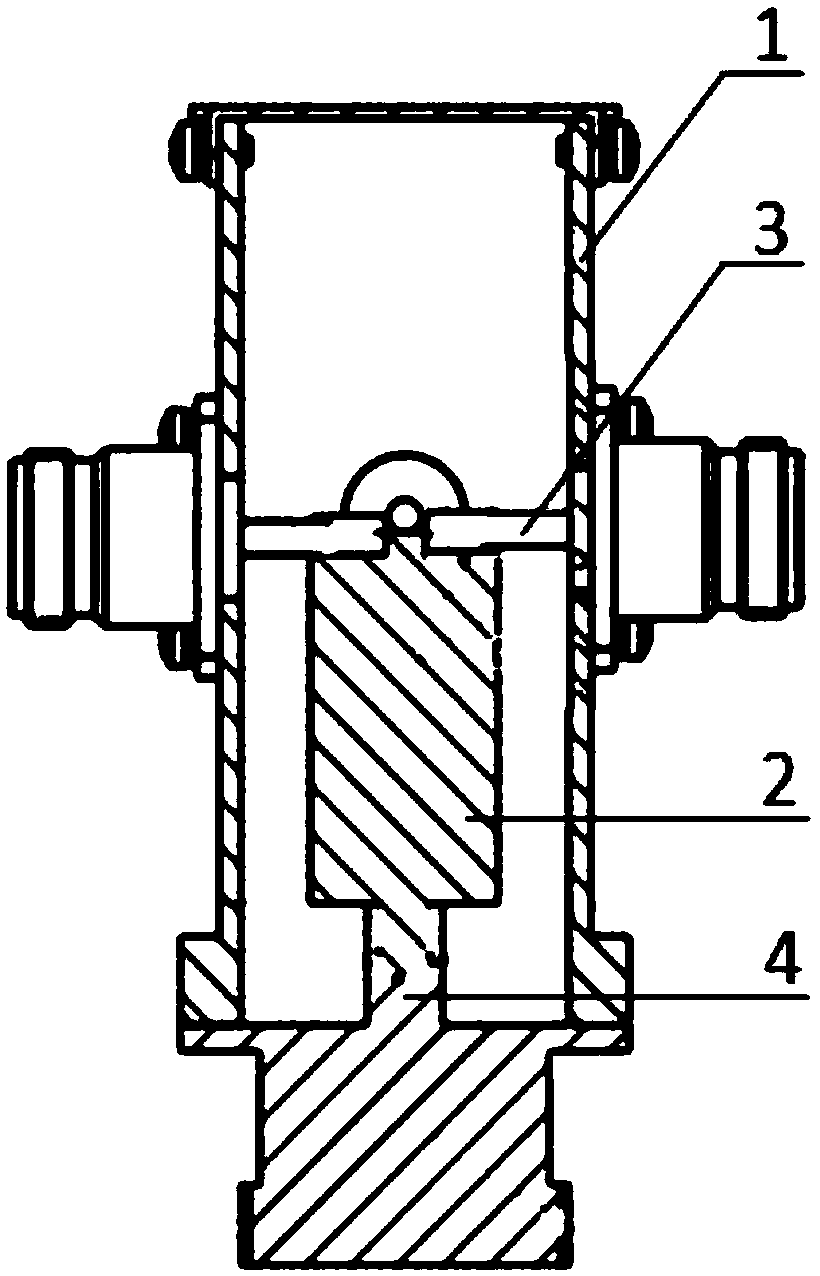

[0016] exist figure 1 Among them, the outer conductor 1 is a square hollow antirust aluminum or stainless steel profile, the inner conductor 2 is a round hollow copper conductor, and the ratio of the inner side length of the outer conductor 1 to the outer diameter of the inner conductor 2 is 1.74±0.1 , the ratio of the length of the outer conductor 1 to the inner conductor 2 is not less than 2.11, and the inner conductor 2 is a quarter of the wavelength. Through simulation, the power bearing capacity of the cavity tends to be the largest under this size, and the volume is five times that of a traditional power combiner. One-third or less, the maximum insertion loss is only 0.3dB. The outer surface of the top of the inner conductor 2 is connected to the probe of the input connector 3 by welding process, the probe of the input connector 3 and the probe of the output connector 4 directly couple the electric field signal, and the energy is transferred between the outer conductor 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com