High-fiber type mandulapalka residue cake and making method

A technology of bean dregs biscuits and oily bean, applied in baking, dough processing, baked food and other directions, can solve problems such as limited application, and achieve the effects of rich nutrition, reasonable formula and full utilization of nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

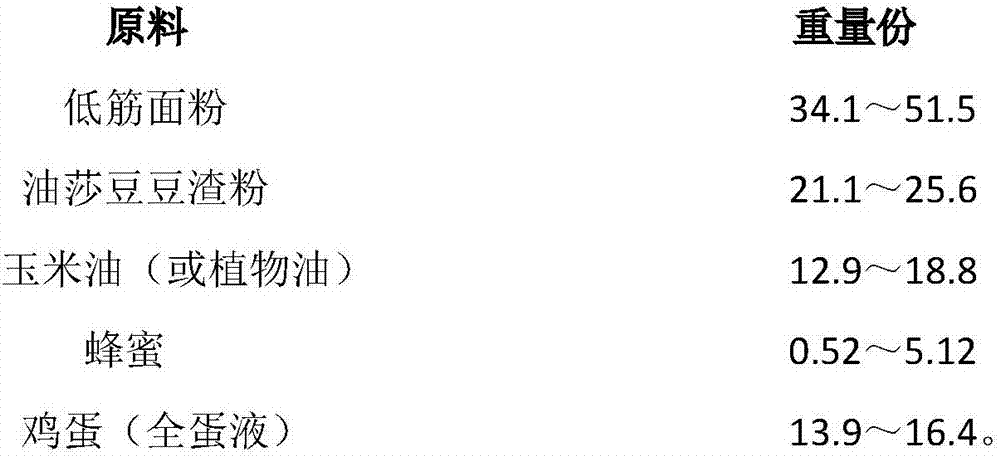

[0049] A kind of high-fiber Yousha bean bean dregs biscuit

[0050] A high-fiber Youshadou bean dregs biscuit, which is prepared from the following raw materials in parts by weight:

[0051]

[0052]

[0053] A kind of preparation method of high-fiber Yousha bean bean dregs biscuit, its steps are:

[0054] A selection of materials: Choose oily beans with full grains, no damage, and no mildew. Remove impurities, wash with water, and dry for later use.

[0055] B. Feed: Mix the oily bean with water in a weight ratio of 1:3.8-4.6, beat and filter, and keep the oily bean dregs for later use.

[0056] C drying: put the obtained Yousha bean and bean dregs in an oven at 70°C, and bake until the water content is lower than 35%, to obtain Yousha bean and bean dregs powder, which should not become sour or scorched due to over-baking.

[0057] D: Whipping of whole egg liquid is the process of using the whole egg (including egg white and egg yolk) as raw material, and whipping it ...

Embodiment 2-6

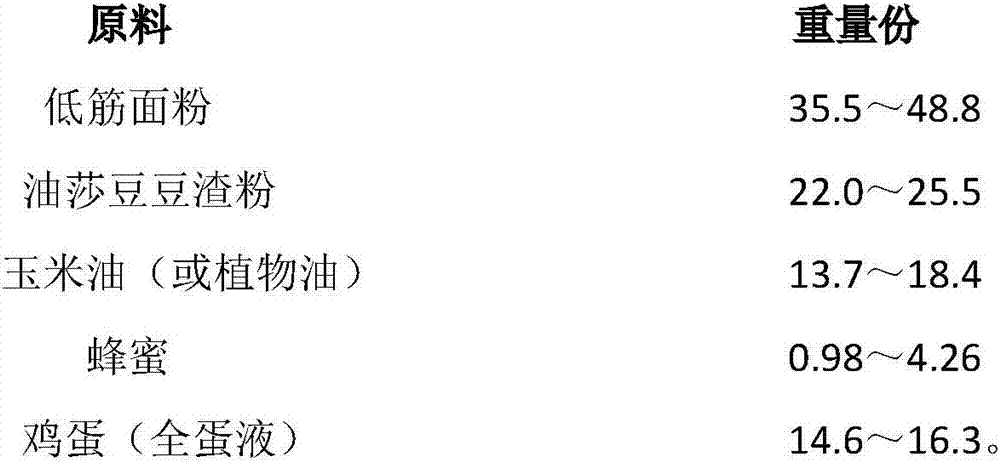

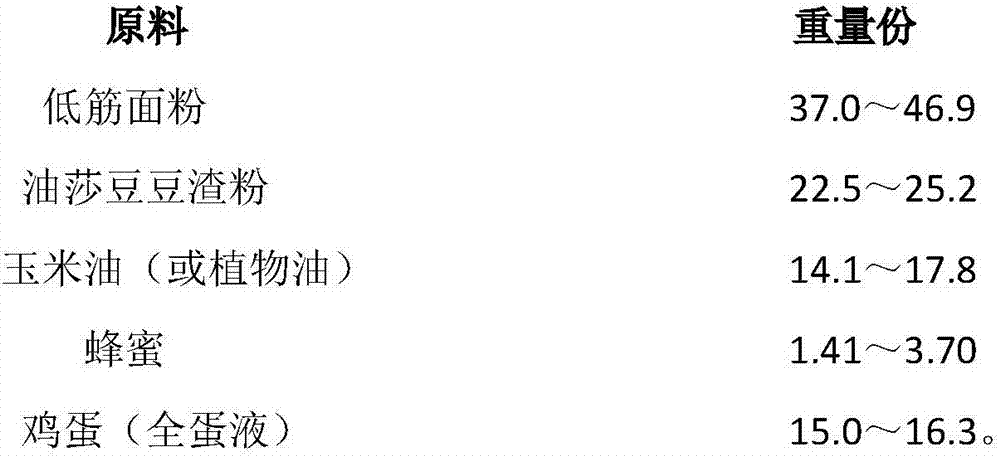

[0063] A high-fiber Youshadou bean dregs biscuit, which is prepared from the following raw materials in parts by weight:

[0064] Raw materials and examples

2

3

4

5

6

Low-gluten flour

34.5

39

44

48

51

Oil Shadou Bean Dregs Powder

21.1

22.5

2.35

24.5

25.6

12.9

15.7

16.4

17.5

18.8

Honey

0.52

2

3

4

5.1

egg

13.9

14.7

15.3

15.8

16.4

total

82.92

93.9

102.2

109.8

116.9

[0065] Its preparation step seven is the same as in Example 1.

[0066] In recent years, with the continuous improvement of people's living standards, the intake of high-calorie, high-protein, high-fat and refined foods has greatly increased, while the intake of dietary fiber has relatively decreased. Because people have ignored the balance of dietary nutrition, As a result, diseases such as "disease of modern civilization" are becoming more and more...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com