Multicolor gradient eye shadow

A technology of eye shadow and pigment, which is applied in the direction of cosmetics, cosmetics, cosmetic preparations, etc., can solve the problems of obvious color difference around the eyes, difficulty in applying makeup, and rough texture, so as to shorten the makeup application time, make the makeup effect better, and be easy to apply The effect of makeup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

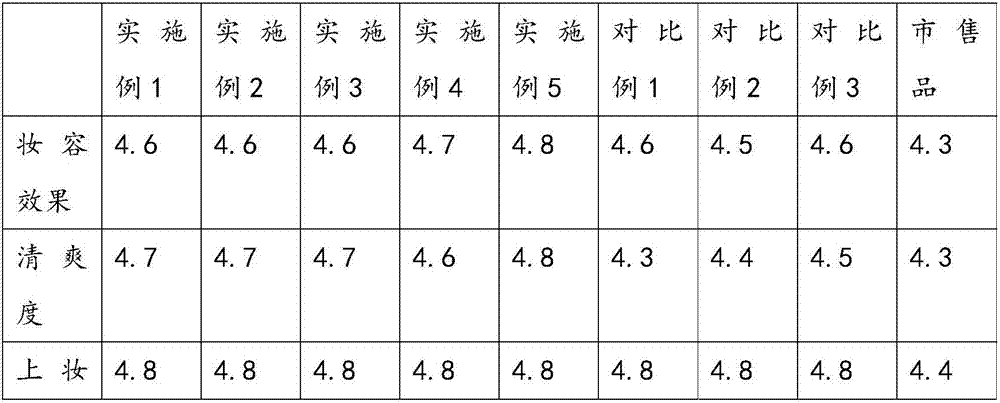

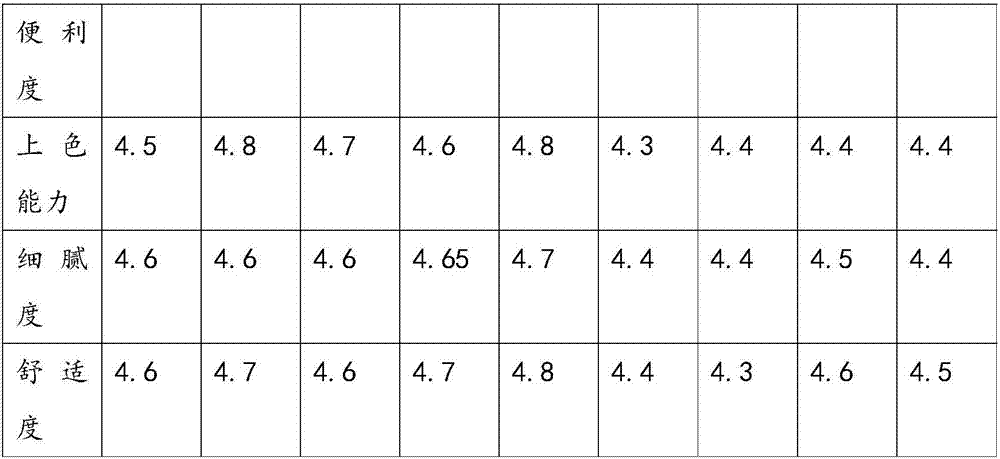

Examples

Embodiment 1

[0025] A multi-color gradient eye shadow, comprising the following components in parts by weight: 50 parts of talcum powder, 15 parts of stearic acid, 20 parts of paraffin, 25 parts of butylene glycol, 6 parts of triethanolamine, 5 parts of pearl powder, 5 parts of simethicone, 4 parts of phenoxyethanol, and 15 parts of natural pigment, specifically, the natural pigment includes 10 parts of kudzu root and 5 parts of Hami melon in parts by weight.

[0026] The preparation of the multi-color gradient eye shadow according to the above raw material ratio comprises the following steps:

[0027] S1: Put butanediol, triethanolamine and phenoxyethanol into the reaction kettle, mix and stir evenly, and heat to dissolve to obtain mixture A, wherein the heating temperature is 70°C, and the heating time is 50 minutes; S2: Stearic acid, paraffin Put them together with simethicone in the reaction kettle, mix and stir evenly, and heat to dissolve to obtain mixture B, wherein the heating temp...

Embodiment 2

[0030] A multi-color gradient eye shadow, comprising the following components in parts by weight: 50 parts of talcum powder, 15 parts of stearic acid, 20 parts of paraffin, 25 parts of butylene glycol, 6 parts of triethanolamine, 5 parts of pearl powder, 5 parts of simethicone, 4 parts of phenoxyethanol, and 15 parts of natural pigment, specifically, the natural pigment includes 7 parts of chestnut and 8 parts of hawthorn by weight.

[0031] Concrete preparation method is identical with embodiment 1.

Embodiment 3

[0033] A multi-color gradient eye shadow, comprising the following components in parts by weight: 50 parts of talcum powder, 15 parts of stearic acid, 20 parts of paraffin, 25 parts of butylene glycol, 6 parts of triethanolamine, 5 parts of pearl powder, 5 parts of simethicone, 4 parts of phenoxyethanol, and 15 parts of natural pigments. Specifically, the natural pigments include 3 parts of coffee beans, 6 parts of blueberries and 6 parts of indigo naturalis by weight.

[0034] Specifically, the preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com