Waste gas deodorization device

A waste gas and spray device technology, applied in gas treatment, dispersed particle filtration, membrane technology, etc., can solve the problems of spraying process, such as high chemical consumption, high water consumption, reduced operation effect, cumbersome operation of spray medium, etc. Stable effect, no drug consumption, easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

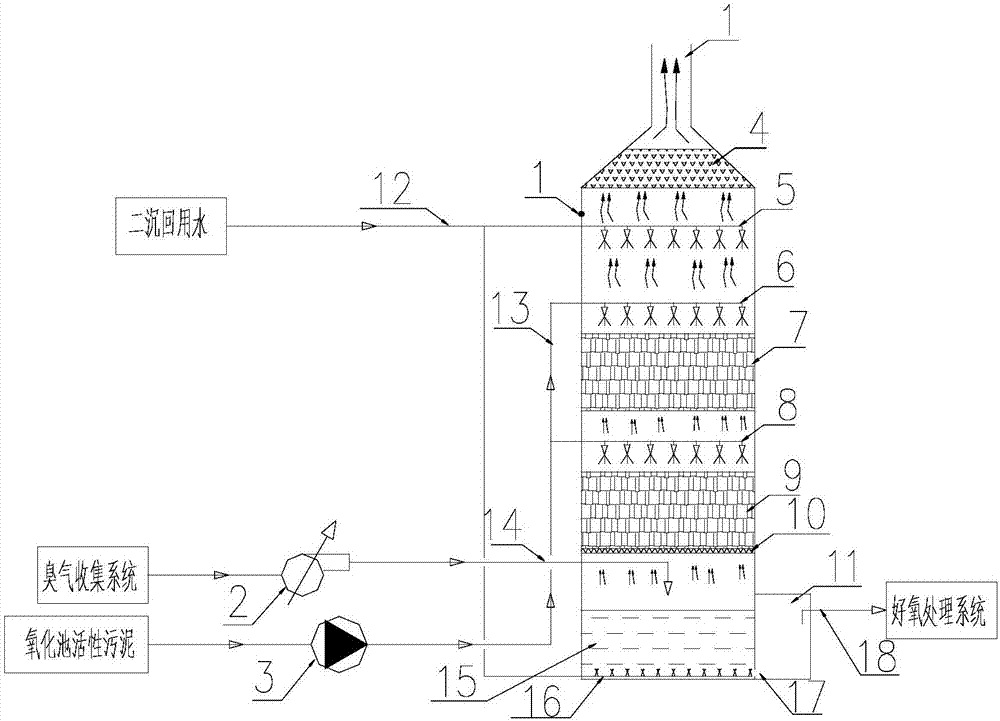

[0018] Embodiment 1 of the present invention, an exhaust gas deodorization device, such as figure 1 As shown, the tower body 1 is included, the top of the tower body 1 is provided with an exhaust port 20, and the tower body 1 is sequentially provided with a spray pump 4, a second biological filter device 7, and a first biological filter device from top to bottom. Device 9 and sump 15, the high-alkalinity secondary sedimentation reuse water passes through the return water supply pipe 12 to the return water spraying device 5 between the spray pump 4 and the second biological filtration device 7, and the other part to Located in the sump 15, the odor collection system passes through the exhaust fan 2 to the air intake duct 14 between the first biological filter device 9 and the sump 15, and the activated sludge in the oxidation tank passes through the activated sludge spray pump 3 And activated sludge spray pipe 13 to the second activated sludge spray device 6 and the first activ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com