Automobile engine crankshaft timing tooling and crankshaft timing and positioning method

A technology of automobile engine and crankshaft journal, which is applied in the fields of automobile engine crankshaft timing tooling and crankshaft timing positioning, which can solve problems such as inaccurate positioning of the crankshaft center hole, broken positioning pins, and affecting strength, so as to avoid deviation, It can withstand large torque and is not easy to damage the crankshaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

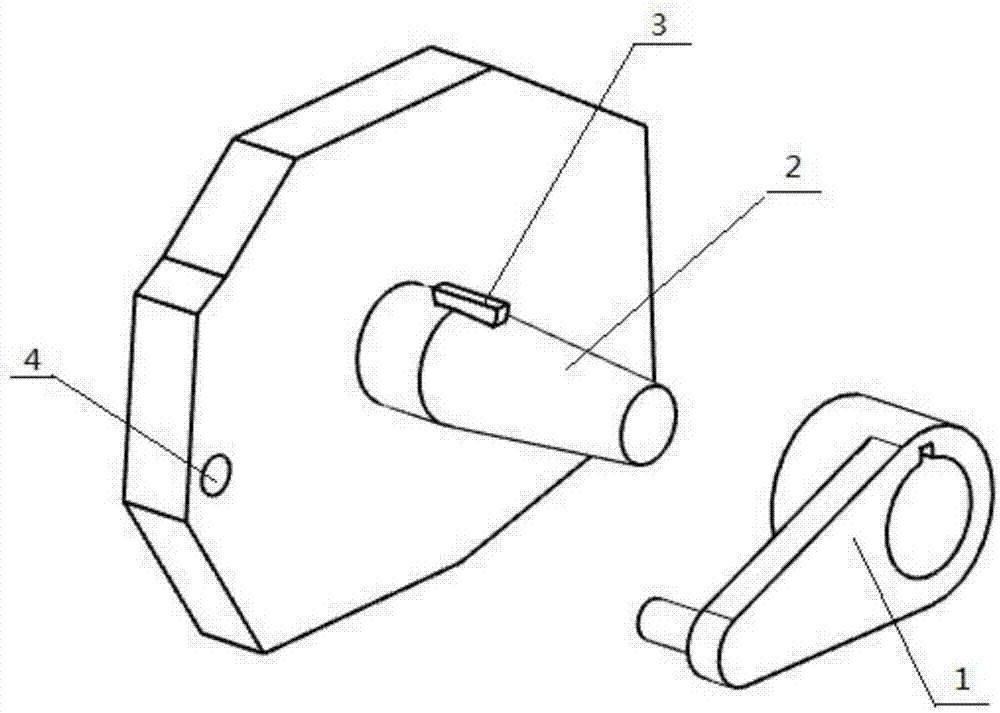

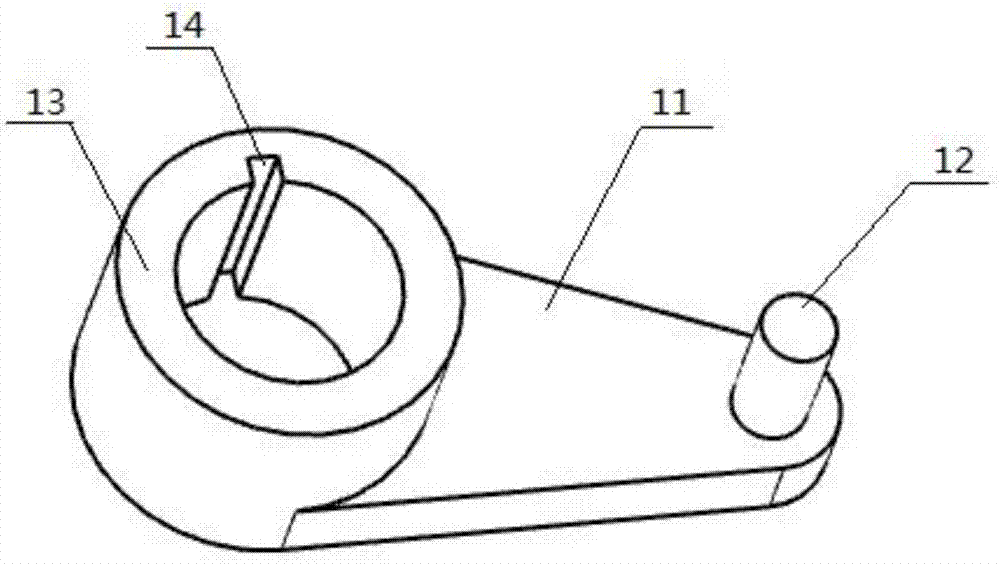

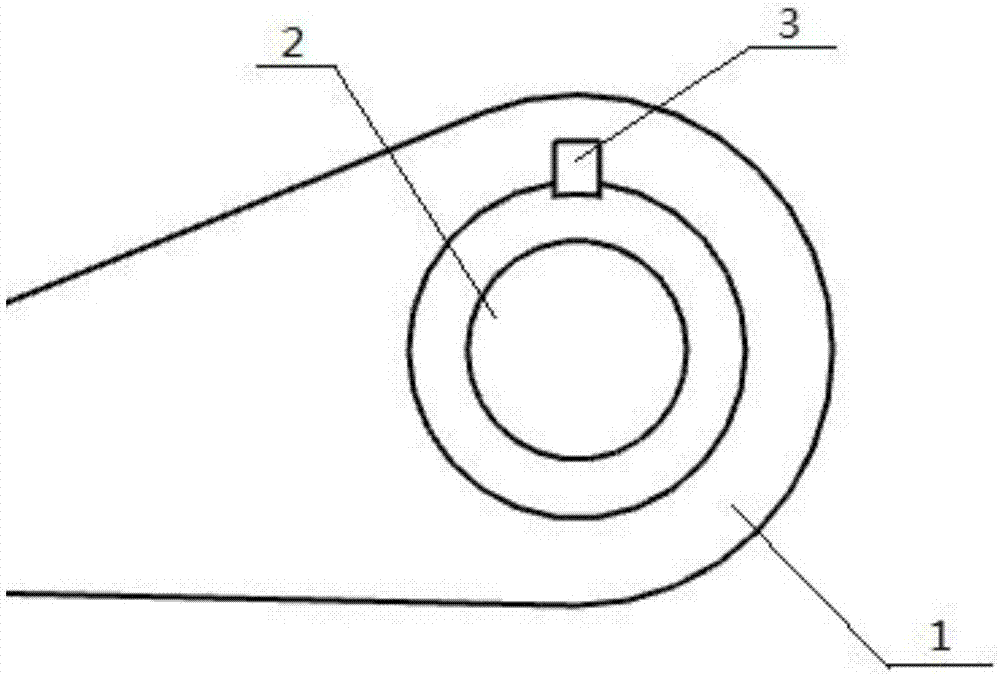

[0037] Such as figure 1 and figure 2 The shown crankshaft timing tooling 1 includes a tooling plate 11, one end of the tooling plate is a cylindrical sleeve 13, the inner hole of the cylindrical sleeve 13 matches the outer circle of the journal of the crankshaft 2, and the inner hole of the cylindrical sleeve 13 A key groove 14 matched with the semicircular key 3 on the journal of the crankshaft 2 is provided, and the other end of the tooling plate 11 is a positioning pin cylinder 12 matched with the crankcase positioning pin hole 4 . The relative position of the keyway 14 in the cylindrical sleeve 13 and the dowel pin cylinder 12 is when the automobile engine crankshaft 2 is in the correct timing position, the relative position of the semicircle key 3 on the crankshaft 2 and the crankcase dowel hole 4. The material of the crankshaft timing tooling 1 is No. 45 steel, which is cheap and easy to process. It has good performance after high-frequency quenching in the later stage...

Embodiment 2

[0048] Such as Figure 6 The shown crankshaft timing tool 1 differs from the crankshaft timing tool described in Embodiment 1 in that the connection between the positioning pin cylinder 12 and the tooling plate 11 is a flexible connection, and the tooling plate 11 is provided with a through hole 15. The positioning pin cylinder 12 passes through the through hole 15 and slides in the through hole 15. The crankshaft timing tool 1 described above can be used for a vehicle engine with a relatively compact structure and limited space during assembly. The shown crankshaft timing tooling 1 carries out the method steps of crankshaft timing positioning as follows:

[0049] (1) Turn the crankshaft 2, so that the piston reaches near the top dead center;

[0050] (2) Install the half-round key 3 in the crankshaft 1 journal keyway;

[0051] (3) Put the cylindrical sleeve 13 at one end of the crankshaft timing tool 1 on the crankshaft 2, and make the semicircular key 3 on the crankshaft 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com