A kind of polyethylene film and preparation method thereof

A polyethylene film and polyethylene technology, applied in the field of polyethylene film, can solve problems such as complex process, high cost, and many procedures, and achieve the effects of simple preparation process, lower requirements, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of polyethylene film provided by the invention may further comprise the steps:

[0027] (1) polyethylene, cross-linking agent and cross-linking auxiliary agent are melt-blended to obtain mixture A;

[0028] (2) forming the mixture A into an initial membrane B, the gel content of the initial membrane B being less than 5% by weight;

[0029] (3) Carrying out high-temperature cross-linking of the initial film B to form a cross-linked film C, the gel content of the cross-linked film C is 20-85% by weight;

[0030] (4) Stretching the crosslinked film C at high temperature to obtain a polyethylene film.

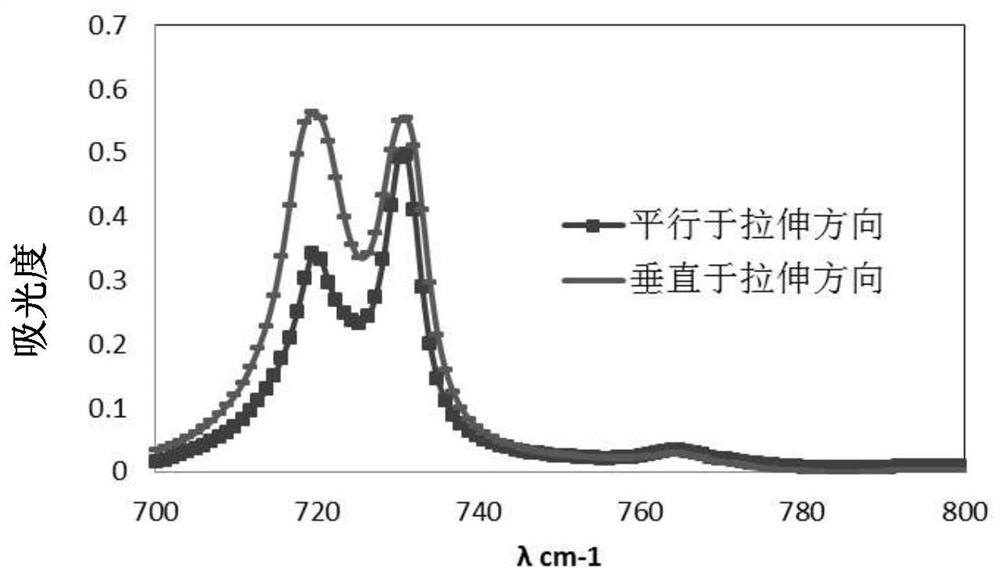

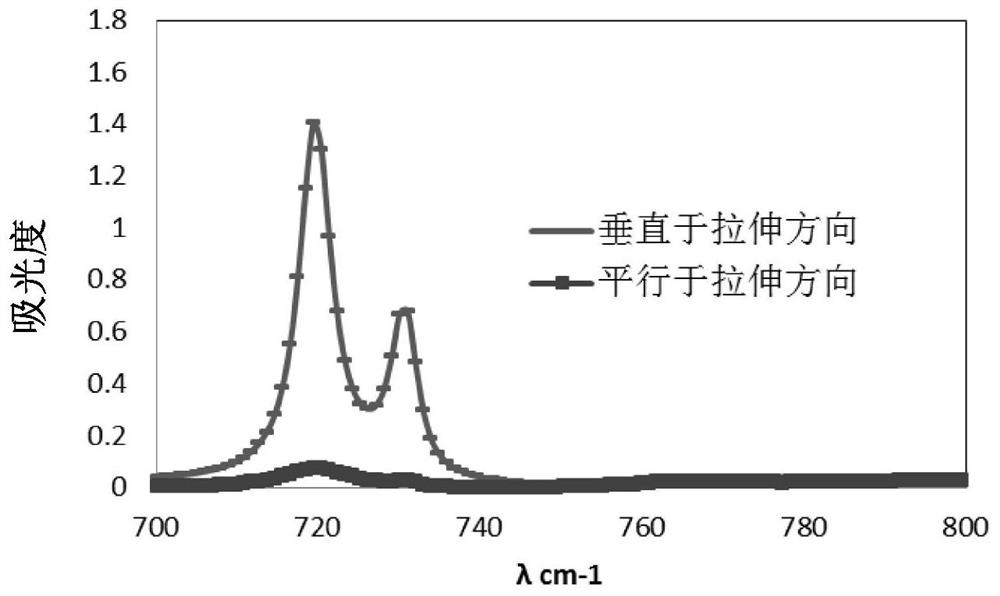

[0031] In the above preparation method, the initial film B is cross-linked at high temperature, and then stretched at high temperature. On the one hand, the existence of cross-linked structure provides the possibility for polyethylene to be stretched at high temperature. On the other hand, The higher stretching temperature ensures the special high or...

Embodiment approach

[0032] In the present invention, the type of the raw material polyethylene is not particularly limited, and may be various existing polyethylenes, for example, high-density polyethylene, low-density polyethylene or linear low-density polyethylene. According to a preferred embodiment of the present invention, the polyethylene is high-density polyethylene, and its density is preferably 0.860g / cm 3 -0.965g / cm3 , more preferably 0.910-0.965g / cm 3 , more preferably 0.920-0.965g / cm 3 , most preferably 0.940-0.960g / cm 3 .

[0033] According to a preferred embodiment of the present invention, the melt index MI of the polyethylene at a temperature of 190°C and a load of 2.16kg is 0.1-100g / 10min, preferably 0.1g / 10min-50g / 10min, more preferably It is 0.5g / 10min-10g / 10min. The melt index MI is measured according to the method specified in ASTM D 1238.

[0034] The present invention does not specifically limit the type of the crosslinking agent. Preferably, the crosslinking agent is ...

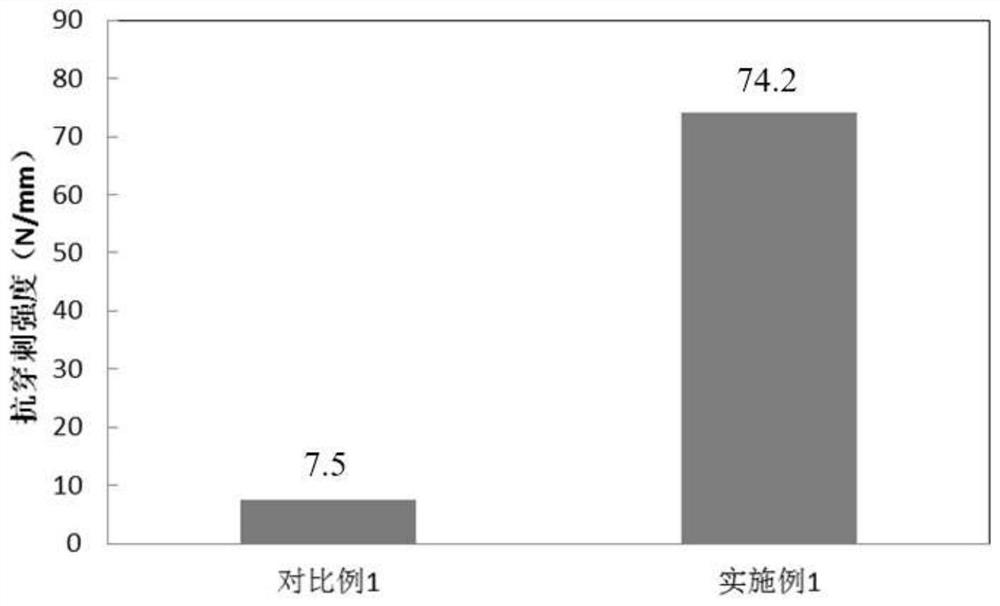

Embodiment 1

[0056] This embodiment is used to illustrate the polyethylene film provided by the present invention and its preparation method.

[0057] (1) Polyethylene film formula:

[0058] The matrix resin is 100g of HDPE (MI=2.0g / 10min, melting temperature is 132.1°C, density is 0.955g / cm 3 ), the crosslinking agent is 0.65g of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, the crosslinking aid is 1g of triallyl isocyanurate and 0.3 g tris(2,2,6,6-tetramethylpiperidinyl nitroxide) phosphite.

[0059] (2) Preparation of polyethylene film:

[0060] The above-mentioned components were melt-blended and extruded to obtain mixture A in a low-shear twin-screw extruder (length-to-diameter ratio was 18 / 1, and the rotating speed of the screw was 100 rpm, the same below). The mixing temperature is 140°C;

[0061] The mixture A was molded by tableting (the molding temperature was 140° C.) to obtain an initial film B, and the initial film B was sampled and determined to have a gel content of 0.5%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com