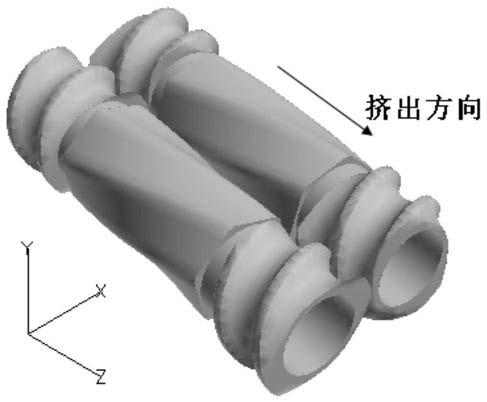

Pbt material for low emission automobile air conditioner air outlet blade and preparation method thereof

A low-emission and anti-oxidant technology, which is applied in the field of PBT materials for low-emission automobile air-conditioning air outlet blades and its preparation, can solve the problems of reducing the emission characteristics of polyamide, reducing the emission characteristics of PC/ABS alloys, and the decline in material performance. Achieve the effect of improving extraction resistance and precipitation, excellent resistance to thermal oxygen degradation, and reducing the impact of emission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

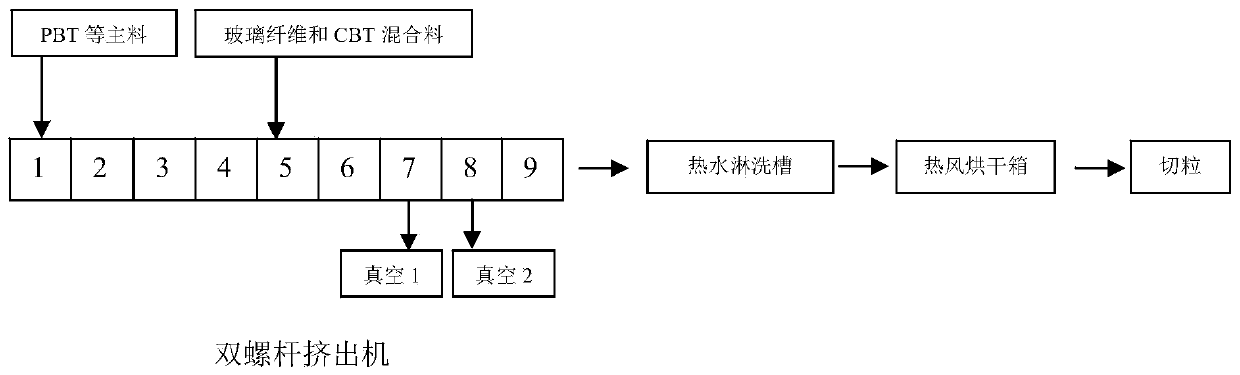

Method used

Image

Examples

Embodiment 1-7 and comparative example 1-7

[0040] The present invention will be described in detail below in conjunction with the examples.

[0041] See Table 1 for the composition ratios of Examples 1-7 and Comparative Examples 1-7.

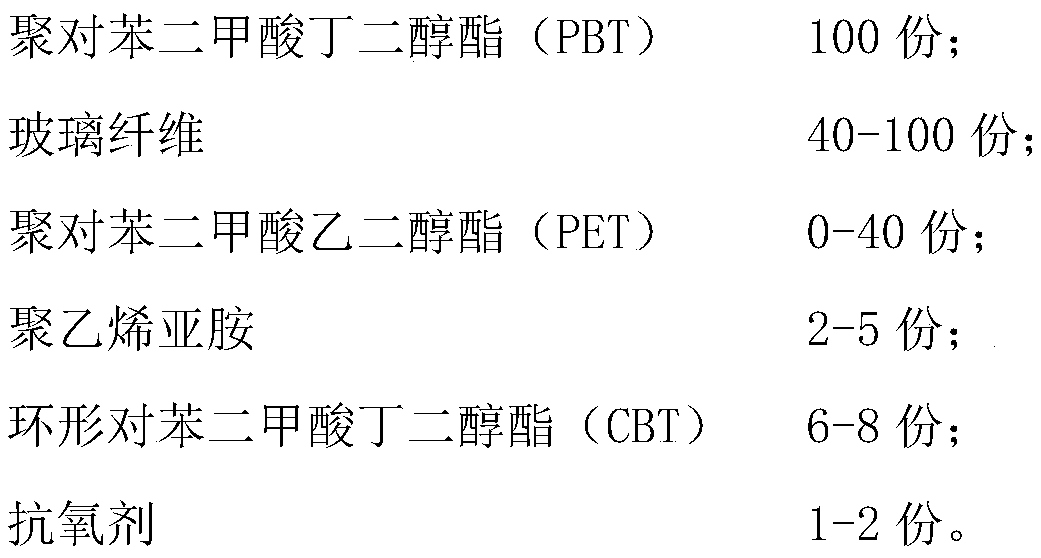

[0042] Polybutylene terephthalate (PBT):

[0043] The PBT resin that adopts in embodiment 1-5 and comparative example 1-7 is the PBT BM434 that Yizheng Chemical Fiber produces, and intrinsic viscosity is 1.2dl / g;

Embodiment 6

[0044] The PBT resin that embodiment 6 adopts is the 1200-211M that Changchun artificial resin produces, and intrinsic viscosity is 0.8dl / g;

Embodiment 7

[0045] The PBT resin that embodiment 7 adopts is the 1200-211X that Changchun artificial resin produces, and intrinsic viscosity is 1.3dl / g.

[0046] Polyethylene terephthalate (PET):

[0047] The PET resin adopted in Examples 1-5 and Comparative Examples 1-7 is CB608S produced by Shanghai Yuanfang, and the intrinsic viscosity is 1.0dl / g;

[0048] The PET resin that embodiment 6 adopts is the L22 that Shanghai Jiacheng polyester factory produces, and intrinsic viscosity is 0.67dl / g;

[0049] The PET resin used in Example 7 is WK-851 produced by Zhejiang Wankai, with an intrinsic viscosity of 0.87dl / g.

[0050] The glass fibers used in Examples 1-7 and Comparative Examples 1-7 are alkali-free chopped glass fibers 303A produced by Chongqing International.

[0051] Polyethyleneimine:

[0052] The polyethyleneimine used in Examples 1-5 and Comparative Examples 1-7 is SP012 produced by Nippon Shokubai Co., Ltd., and its molecular weight is about 1200;

[0053] The polyethylenei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com