Manufacturing process for preparing double-component nano fibers

A technology of nanofiber and production process, which is applied in the field of production process for preparing two-component nanofiber, and can solve the problems of small output and long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

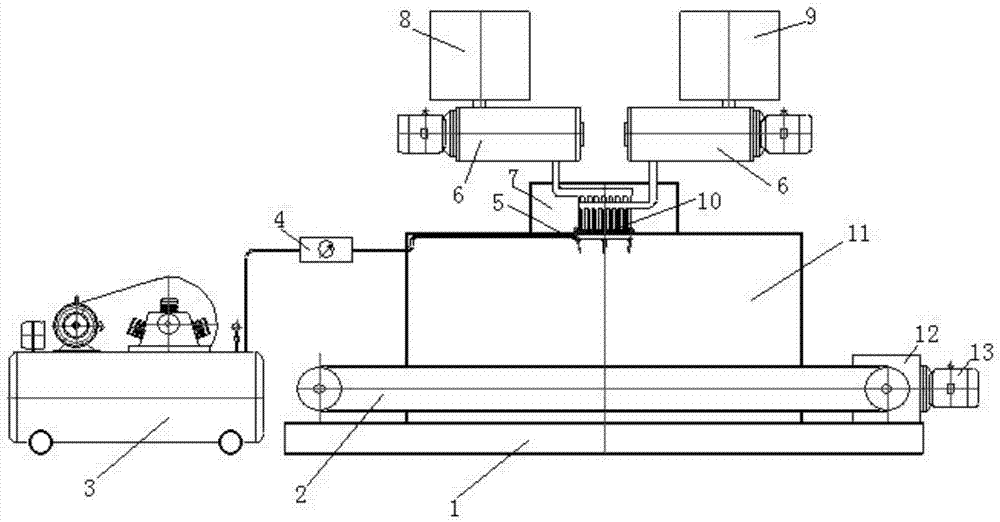

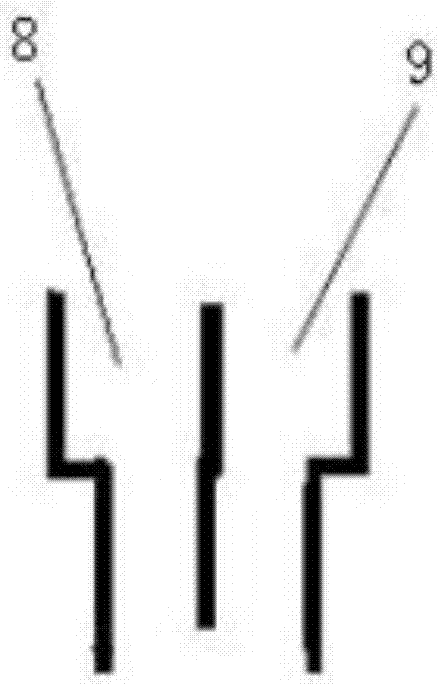

[0024] Such as figure 1 As shown, a device for preparing two-component nanofibers includes a frame 1, a conveyor belt 2, an air compressor 3, an air pressure regulator 4, a compressed air nozzle 5, a screw conveyor 6, a mixing bin 7, a A hopper 8, a second hopper 9, a spinning die 10, a finished product bin 11, a reducer 12 and a motor 13.

[0025] A finished product warehouse 11 is installed on the frame 1, and a conveyor belt 2 passes through the bottom of the finished product warehouse 11. The conveyor belt 2 is connected with a speed reducer 12, and the speed reducer 12 is controlled by a motor 13; A compressed air nozzle 5 is installed in the top of the storehouse 11, and the compressed air nozzle 5 is connected with the air compressor 3, and an air pressure regulator 4 is also provided between the air compressor 3 and the compressed air nozzle 5 to adjust the air pressure.

[0026] The top of the finished product bin 11 is fixedly equipped with a mixing bin 7, and a spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com