A nano-water-based thermal transfer ink suitable for high-speed printing with Kyocera nozzles

A medium-high-speed thermal transfer printing technology, applied in transfer printing, ink, printing, etc., to achieve good stability, good standby performance, and reduce the risk of electrochemical corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

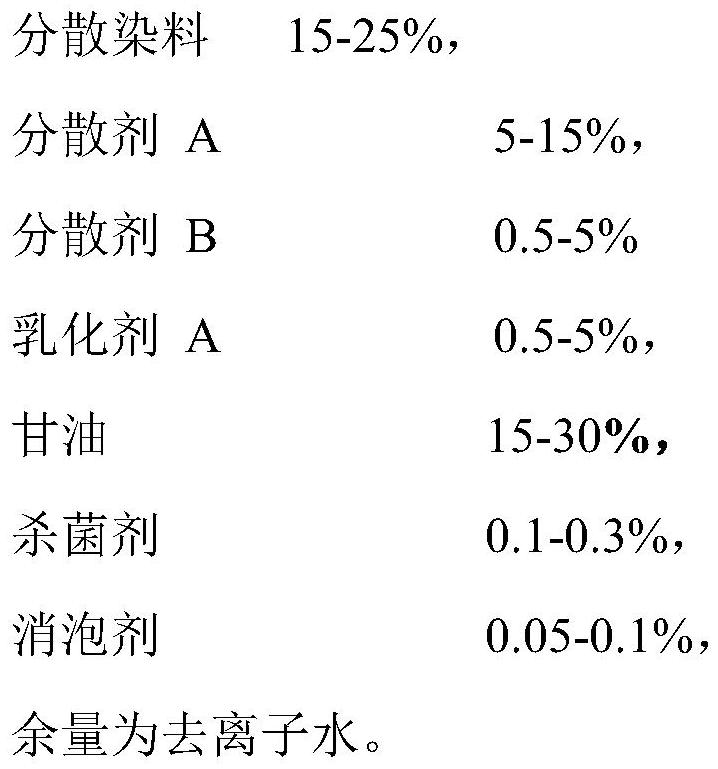

[0046] Raw material preparation for a color paste: weigh R60 20%, lignin 970 8.5%, emulsifier A233S 3%, 44000 3.5%, 690W 1.5%, glycerin 20%, PROXEL GXL 0.2%, defoamer 104E 0.05 %, the balance is deionized water.

[0047] The preparation method of nano-color paste: put R60, lignin 907, lignin 907, 44000, A233S, 690W, glycerin, PROXEL GXL, defoamer 104 and deionized water into a total of 200KG, and put them into the dispersion barrel at 1200rpm for 2 hours, and then The 80-mesh filter bag is filtered and transferred to the grinder for dispersion and grinding. The speed of the grinder is 1200-1250rpm, the grinding time is controlled at about 45-60h, the flow rate of the outlet is 6-8kg / min, and the temperature of the outlet is controlled at 40±5°C, to obtain nano-scale color paste with a particle size of 100nm≤D50≤130nm, 250nm≤D99≤280nm; the grinder is a NETZSCH 10L horizontal nano-sand mill imported from Germany, and the cylinder and tip of the grinder The support is made of we...

Embodiment 9

[0059] A kind of raw material preparation of nano water-based thermal transfer printing ink: by weight, take by weight 28% of the color paste of embodiment 1, 1,3-propanediol 5%, glycerol 25%, 1,5-pentanediol 10% %, DS960 0.8%, emulsifier B 690W 0.5%, ProxelGXL 0.1%, and the balance is deionized water.

[0060] The preparation method of above-mentioned nano water-based thermal transfer printing ink, comprises the following steps:

[0061] (1) Turn on the mixer, add deionized water, and then add 1,3-propanediol, glycerin, 1,5-pentanediol, DS960, emulsifier 690W and Proxel GXL while stirring at a speed of 500rpm, and stir for 20 -30min to mix evenly, add the nanoscale dispersion color paste of embodiment 1, continue to stir 30-60min with the speed of 600rpm;

[0062] (2) Test the viscosity and surface tension of the homogeneously mixed mixture in step (1). The viscosity range is 5-6.5mpa.s, and the surface tension range is 30-40mN / cm, all qualified, and then aged at 35°C After...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com