Steel-plastic conversion joint for heavy anti-corrosion fuel gas and manufacturing method thereof

A steel-plastic conversion joint, heavy-duty anti-corrosion technology, applied in the direction of pipeline anti-corrosion/anti-rust protection, pipe/pipe joint/pipe fittings, damage protection, etc. and other problems, to achieve excellent anti-corrosion effect, reduce the number of settings, and good thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

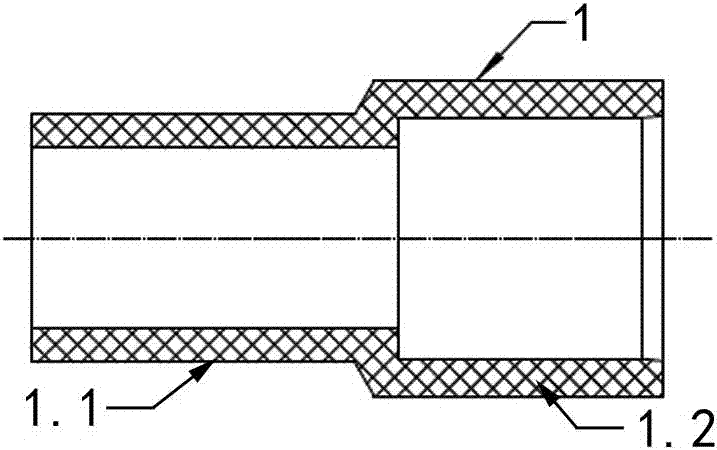

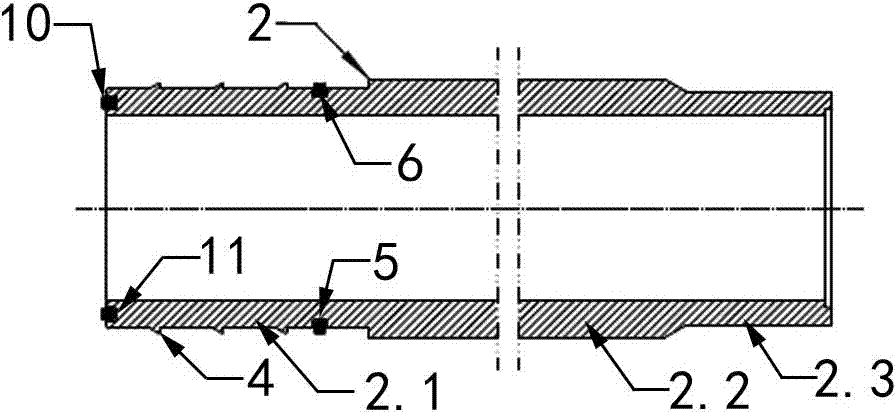

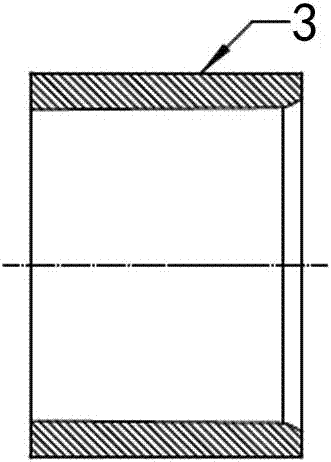

[0037] refer to Figure 1-5 , a steel-plastic transition joint for heavy anti-corrosion gas described in this specific embodiment, comprising a polyethylene plastic pipe fitting 1, a metal inner lining 2, a metal outer sleeve 3, an annular barb structure 4, a first annular sealing groove 5, The first sealing ring 6, the electrogalvanized layer 7, the hot melt adhesive winding layer 8, the PEX heat-shrinkable sleeve 9, the second sealing ring 10 and the second sealing groove 11, and the polyethylene plastic pipe fitting 1 includes a large diameter integrally arranged Pipe section 1.1 and small-diameter pipe section 1.2, the inner diameter of the large-diameter pipe section 1.1 is greater than the inner diameter of the small-diameter pipe section 1.2, the inner diameter of the small-diameter pipe section 1.2 is equal to the inner diameter of the metal lini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com