Petroleum pipeline scale-prevention and demulsification heating equipment and oil gas-water separation method

A technology for oil pipelines and heating equipment, applied in separation methods, pipeline heating/cooling, liquid separation through thermal diffusion, etc., can solve the problems of poor oil-water separation effect, short pipeline service life, serious pipeline scaling, etc., and achieve good results. , prolong the service life, the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

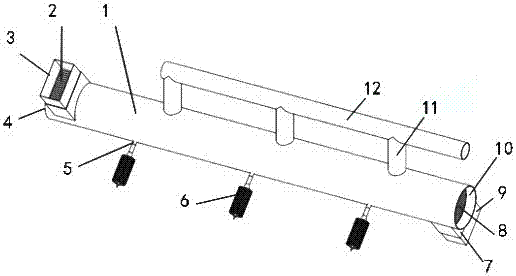

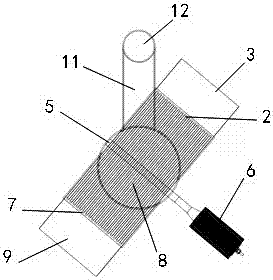

[0024] Taking the hot steam heat source as an example, the crude oil incoming liquid enters the integrated equipment of the present invention from the left end of the crude oil incoming liquid inlet 4, and first undergoes the coalescence and separation treatment of the coalescing sloping plate bundle 8, and the inclination angle of the sloping plate bundle is formed along the axial direction of the pipeline. Set at 40 degrees, the material of the plate bundle is made of stainless steel material with good elasticity and good absorption of oil droplets, the plate bundles are set in parallel, and the plate spacing is set at 10mm according to the characteristics of the incoming crude oil. First, the hot steam enters the heat source inlet 2 in the middle of each inclined plate through the heat source inlet header 3. The hot steam flows inside the inclined plate and exchanges heat with the crude oil and liquid between the inclined plates. Finally, the steam-water mixture after heat ex...

Embodiment 2

[0026] Taking the heat source of heat conduction oil as an example, the crude oil incoming liquid enters the integrated equipment of the present invention from the crude oil incoming liquid inlet 4, and first undergoes coalescence and separation treatment of the coalescing sloping plate bundle 8, and the inclination angle of the sloping plate bundle is 50° The plate bundle is made of stainless steel material with good elasticity and good absorption of oil droplets. The plate bundles are arranged in parallel, and the plate spacing is set at 10mm according to the characteristics of the incoming crude oil. First, the heat transfer oil enters the heat source inlet 2 in the middle of each swash plate through the heat source inlet header 3, the heat transfer oil flows inside the slant plate and exchanges heat with the crude oil and liquid between the slant plates, and finally the heat transfer oil exits the heat source after heat exchange 7 and the heat source outlet header 9 are dis...

Embodiment 3

[0028] Taking the hot water heat source as an example, the crude oil incoming liquid enters the integrated equipment of the present invention from the left end of the crude oil incoming liquid inlet 4, and first undergoes coalescence and separation treatment of the coalescing inclined plate bundle 8. Set at 45 degrees, the material of the plate bundle is made of stainless steel material with good elasticity and good absorption of oil droplets, the plate bundles are arranged in parallel, and the plate spacing is set at 10mm according to the characteristics of the incoming crude oil. First, the hot water enters the heat source inlet 2 in the middle of each swash plate through the heat source inlet header 3, and the hot water flows inside the slant plate and exchanges heat with the crude oil and liquid between the slant plates, and finally the gas-water mixture after the heat exchange flows from The heat source outlet 7 and the heat source outlet header 9 are discharged.

[0029]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com