Forage grass kneading machine

A rack and fan technology, applied in feed, food science, application and other directions, can solve the problems of unutilized crop straw, poor straw palatability, lack of processing machinery, etc., to achieve simple structure, improved palatability, production Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The following description is only used to explain the present invention, not to limit the present invention.

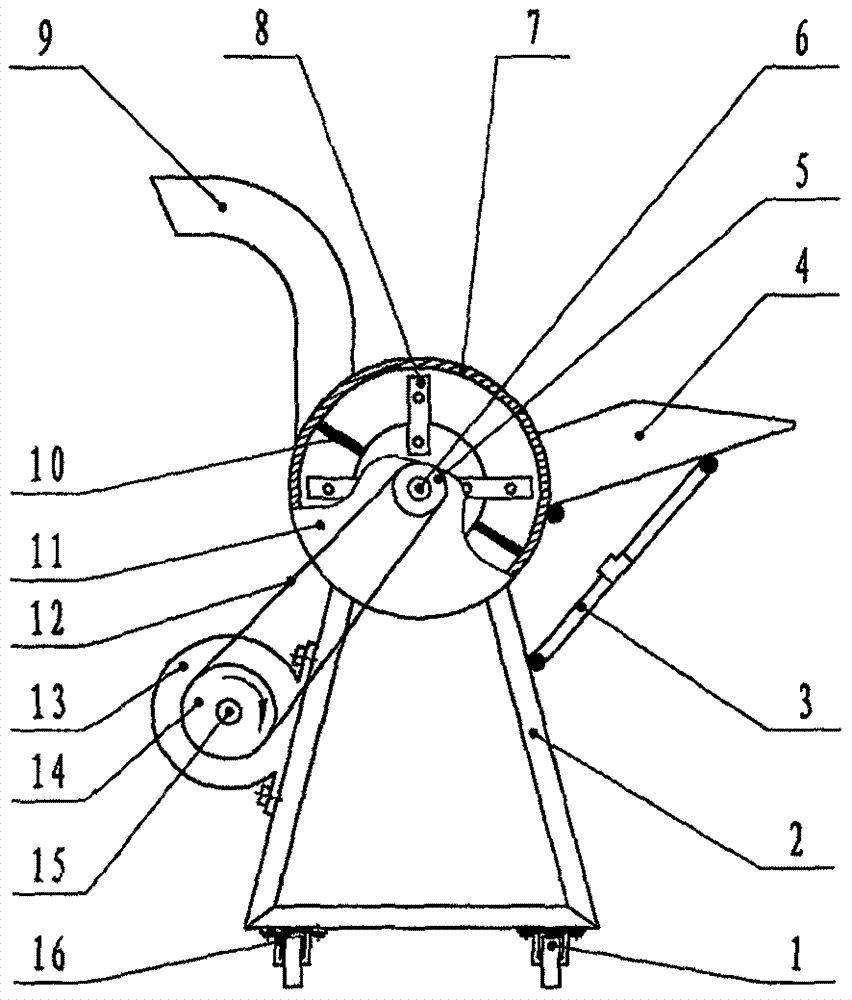

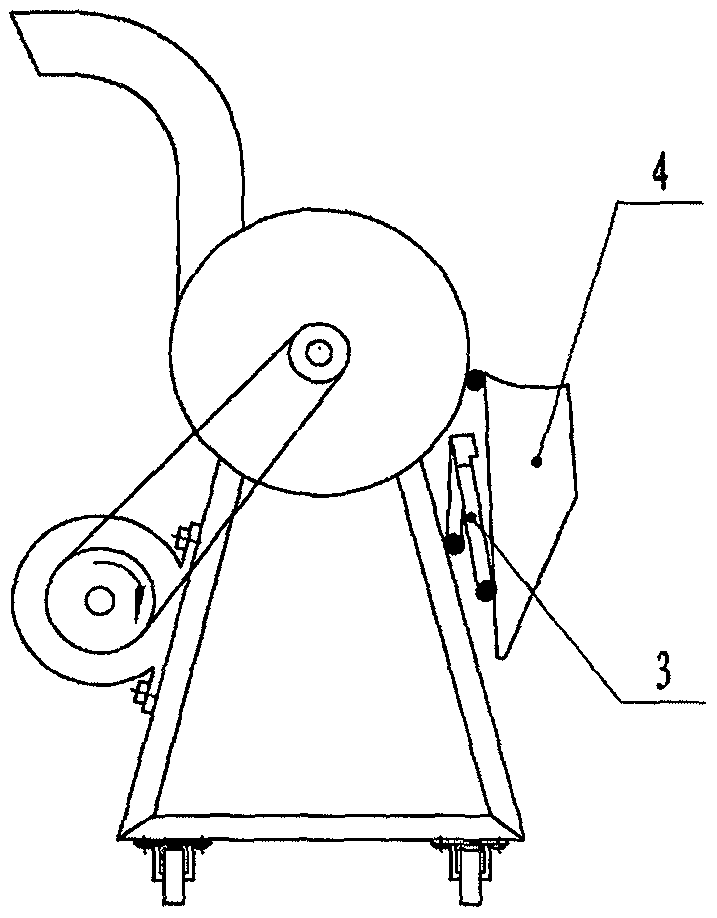

[0019] Such as figure 1 , figure 2 As shown, a kind of forage kneading machine of the present invention is made up of frame 2 kneading assembly 11 feeding trough 4 discharging barrel 9 power assembly 13 running gears 16.

[0020] The drum shaft 6 is installed on the working chamber housing 7, the hammer blade 8 and the fan 10 are installed on the drum shaft 6, and the outlet of the fan is connected to the discharge cylinder 9 by welding. The drum pulley 5 is installed on the drum shaft 6, connected with the motor pulley 14 installed on the motor rotor shaft 15 through the belt 12, the power assembly 13 is installed on one side of the frame, and the feeding trough 4 is connected to the housing 7 through a hinge When working,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com