Graphite dust electrostatic dust collection system and method

An electrostatic precipitator and graphite dust technology, which is applied in the dust removal field of exhaust gas purification treatment, can solve the problems of operator health threat, pollution of workshop environment, difficult settling and other problems, and achieves the effect of reasonable process design, convenient operation and maintenance, and high dust removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

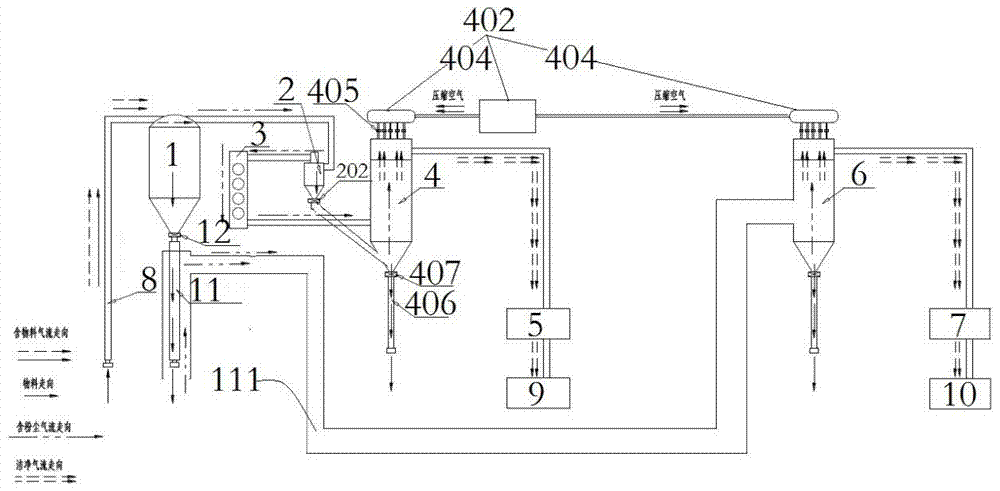

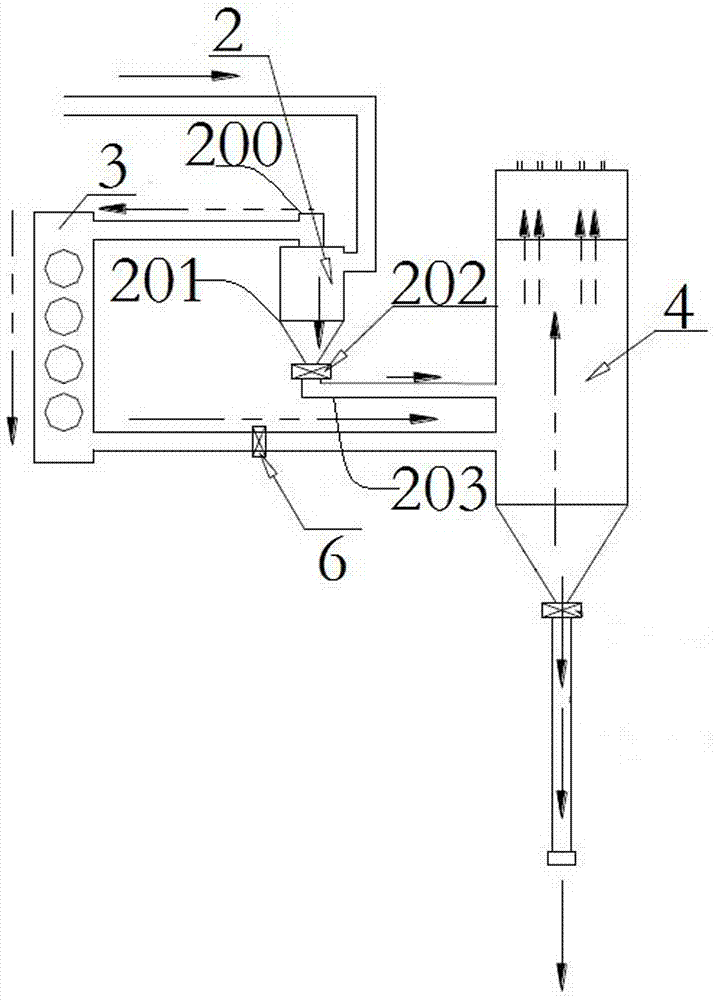

[0041] Such as Figure 1~5 As shown, a graphite dust electrostatic precipitator system is provided in this embodiment, which is used for anode roasting, including a telescopic suction pipe 8, a storage tank 1, a cyclone dust collector 2, an air cooler 3, a first Bag filter 4, the first Roots blower 5 and the first electrostatic precipitator 9;

[0042] The bottom of the cyclone dust collector 2 is connected with the bag filter 4 through a pipeline;

[0043] The first Roots blower 5 is used to provide power for conveying the high-temperature graphite dust, and the high-temperature graphite dust is conveyed by the negative pressure air generated by the first Roots blower 5;

[0044] It also includes a second bag filter 6, a second Roots blower 7 and a second electrostatic precipitator 10, and the second bag filter 6 communicates with the second Roots blower 7 through a pipeline;

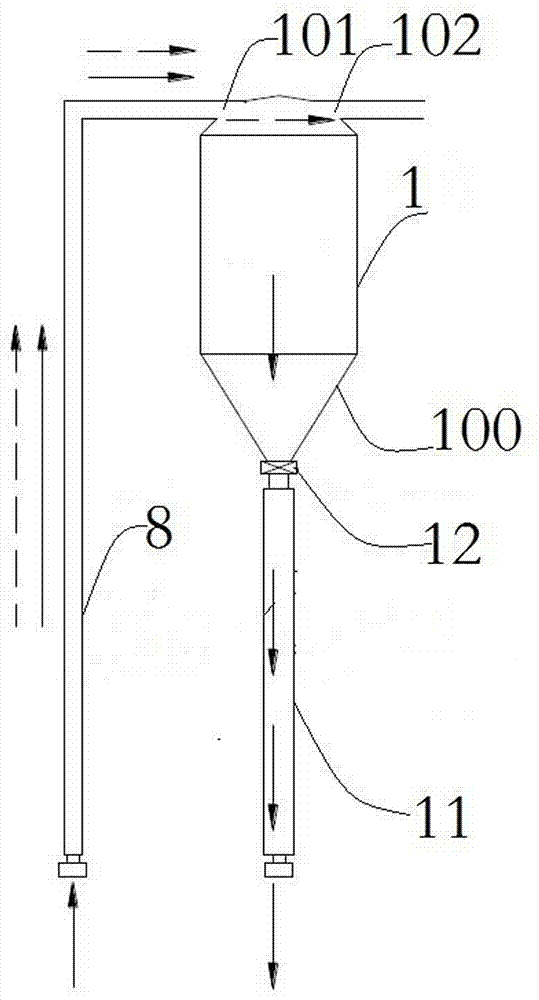

[0045] The storage tank 1 includes a telescopic discharge pipe 11 arranged at the bottom, and a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com