Automatically cleaned ultraviolet water sterilizer

An automatic cleaning and sterilizer technology, which is applied in the fields of cleaning hollow objects, water/sewage treatment, chemical instruments and methods, etc. It can solve the problems of not being able to accommodate lamps at the same time, occupying a large space, and being limited in space, so as to achieve the distribution of ultraviolet illuminance. Uniform, not easy to corrode failure, guaranteed lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0033] The existing technology cannot simultaneously solve the problems of automatic cleaning of a small-scale ultraviolet water sterilizer with only one lamp tube, avoiding the sideways moment that causes the cleaning mechanism to tilt, and ensuring a balanced distribution of ultraviolet illuminance.

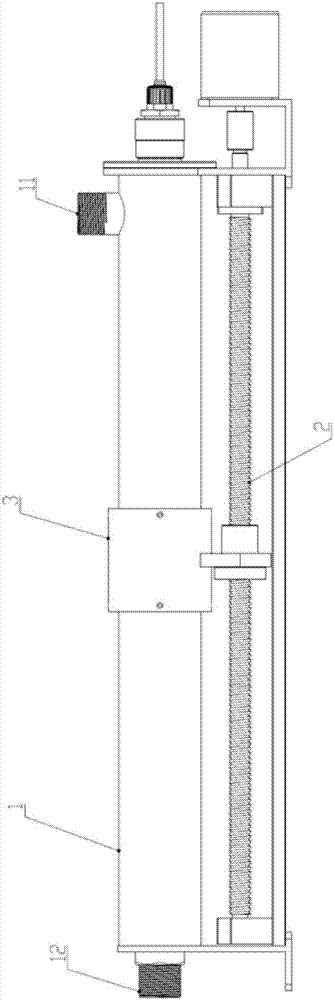

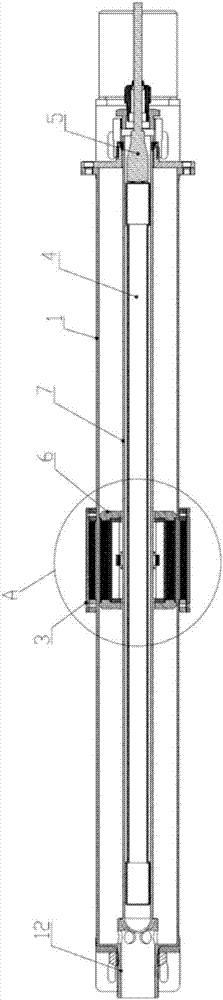

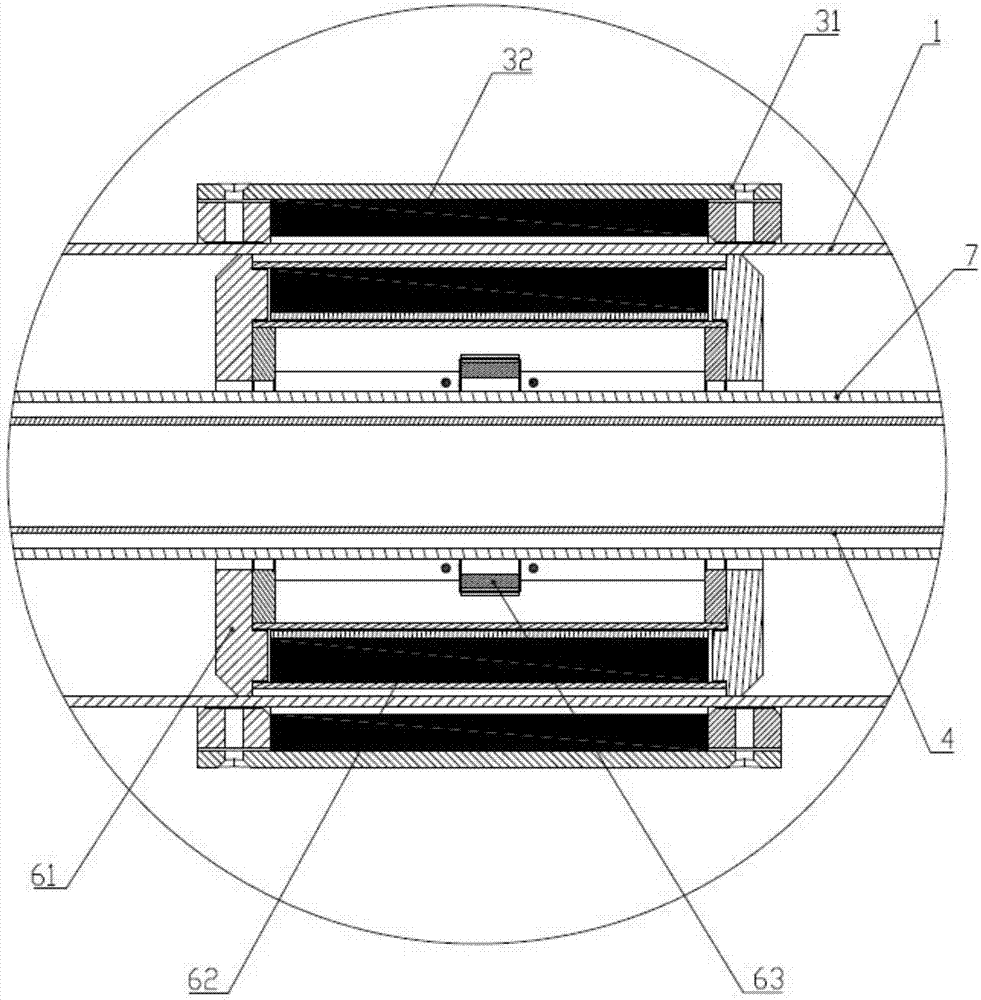

[0034] For this reason, the invention provides a kind of automatic cleaning ultraviolet water sterilizer, see figure 1 and figure 2, the ultraviolet water sterilizer includes: a housing 1, a driving device 2, a cleaning device 6 for cleaning the casing, a magnetic transmission device 3 for driving the cleaning device, a casing 7, a lamp 4 and a cable 5. The lamp tube 4 is arranged inside the sleeve 7 , and the sleeve 7 is arranged inside the casing 1 .

[0035] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com