Marble crystal surface agent and preparation method thereof

A technology of crystal surface agent and marble, applied in the field of preparation of stone surface care agent, can solve the problems of poor air permeability, yellowing, non-slip, etc., and achieve the effect of reducing the problem of agglomeration, maintaining fluidity and maintaining activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

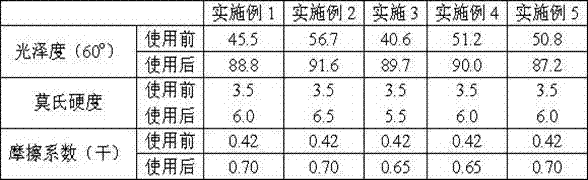

Examples

Embodiment 1

[0028] A marble crystal surface agent, consisting of the following components and weight percentages: abrasive cerium oxide 18%, filler fumed silica 2%, crystallization hardener magnesium fluorosilicate 16%, wetting agent polyethylene glycol 600 1.5 %, modifier KH570 2.5%, acid regulator acetic acid 3%, and the balance is water.

Embodiment 2

[0030] A marble crystal surface agent, which is composed of the following components and weight percentages: 15% abrasive silica, 4% filler fumed silica, 10% crystallization hardener magnesium fluorosilicate and 5% zinc fluorosilicate, moistening Wet agent polyvinyl alcohol 1799 2.5%, modifier KH792 2.5%, acid regulator succinic acid 2.5%, and the balance is water.

Embodiment 3

[0032] A marble crystal surface agent, which is composed of the following components and weight percentages: 10% abrasive silica, 2% filler fumed silica, 15% crystallization hardener magnesium fluorosilicate, and 2.5% wetting agent glycerin , modifier KH560 1%, acid regulator oxalic acid 0.7%, and the balance is water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com