Shutter door positioning bracket

A technology for positioning brackets and rolling shutters, applied to windows/doors, door/window protection devices, building components, etc., can solve the problems of high manufacturing cost, inconvenient adjustment, complex structure, etc., and achieve the effect of improving hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

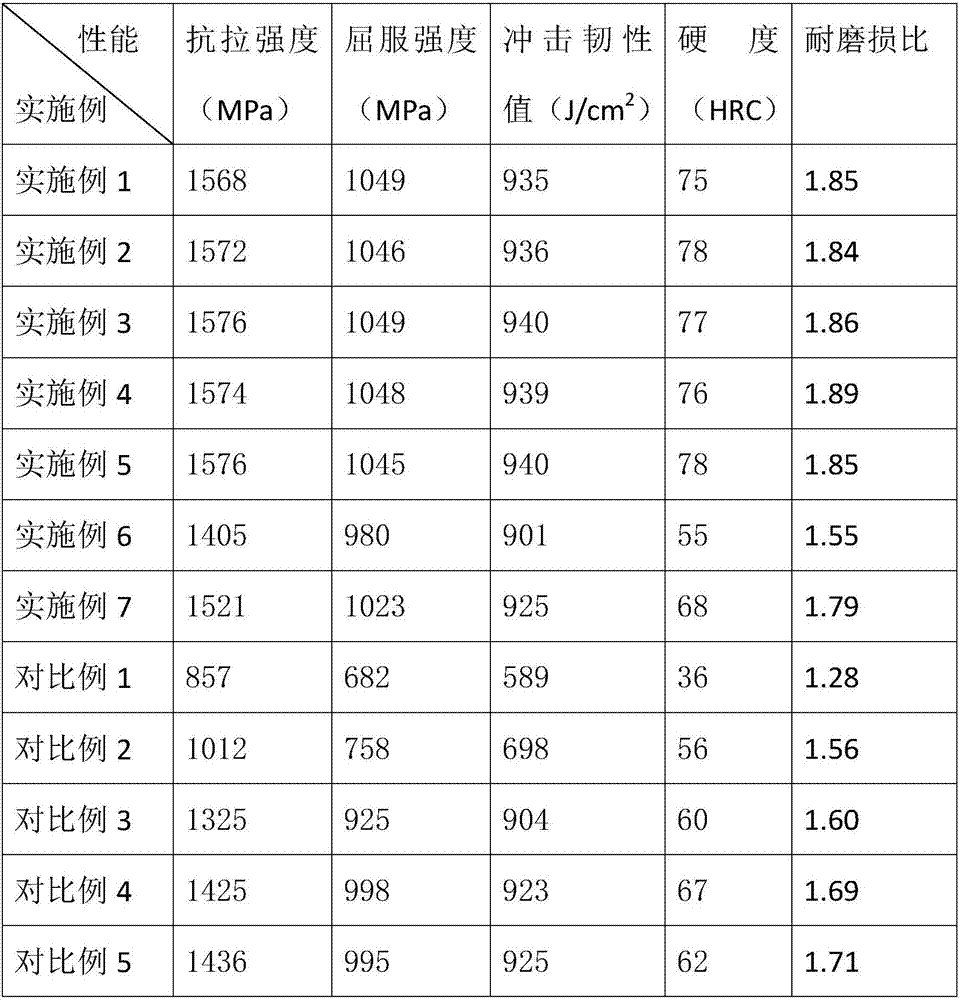

Examples

Embodiment 1

[0029] Ball milling: Weigh the magnesium alloy raw material except for NiTi long fibers to prepare the rolling door positioning bracket, put it into a ball mill and carry out ball milling under Ar gas to obtain powder; wherein, the magnesium alloy specifically includes the following components by mass percentage: Al: 7.5-8.0 %, Zn: 0.55-0.65%, Mn: 0.15-0.25%, Si: 0.05-0.1%, La: 0.5-0.8%, Nd: 0.8-1.2%, NiTi long fiber: 0.6-0.85%, the balance is Mg ; Also added stearic acid in the ball milling process, the addition of stearic acid is 1.2-1.4% of the magnesium alloy raw material quality; The ball mill is a planetary ball mill, the ball milling speed is 420-430r / min, and the ball milling time is 11 -13h;

[0030] Hot-pressed billets: hot-press the powder and NiTi long fibers into a preform in a single-item pressing mold; the hot-pressing specifically includes the following steps: raise the temperature to 200-220°C and keep it for 0.5-0.7h, then raise the temperature to 240-250°C, ...

Embodiment 2

[0035]Ball milling: Weigh the magnesium alloy raw material except for NiTi long fibers to prepare the rolling door positioning bracket, put it into a ball mill and carry out ball milling under Ar gas to obtain powder; wherein, the magnesium alloy specifically includes the following components by mass percentage: Al: 7.5-8.0 %, Zn: 0.55-0.65%, Mn: 0.15-0.25%, Si: 0.05-0.1%, La: 0.5-0.8%, Nd: 0.8-1.2%, NiTi long fiber: 0.6-0.85%, the balance is Mg ; Also added stearic acid in the ball milling process, the addition of stearic acid is 1.2-1.4% of the magnesium alloy raw material quality; The ball mill is a planetary ball mill, the ball milling speed is 420-430r / min, and the ball milling time is 11 -13h;

[0036] Hot-pressed billets: hot-press the powder and NiTi long fibers into a preform in a single-item pressing mold; the hot-pressing specifically includes the following steps: raise the temperature to 200-220°C and keep it for 0.5-0.7h, then raise the temperature to 240-250°C, ...

Embodiment 3

[0041] Ball milling: Weigh the magnesium alloy raw material except for NiTi long fibers to prepare the rolling door positioning bracket, put it into a ball mill and carry out ball milling under Ar gas to obtain powder; wherein, the magnesium alloy specifically includes the following components by mass percentage: Al: 7.5-8.0 %, Zn: 0.55-0.65%, Mn: 0.15-0.25%, Si: 0.05-0.1%, La: 0.5-0.8%, Nd: 0.8-1.2%, NiTi long fiber: 0.6-0.85%, the balance is Mg ; Also added stearic acid in the ball milling process, the addition of stearic acid is 1.2-1.4% of the magnesium alloy raw material quality; The ball mill is a planetary ball mill, the ball milling speed is 420-430r / min, and the ball milling time is 11 -13h;

[0042] Hot-pressed billets: hot-press the powder and NiTi long fibers into a preform in a single-item pressing mold; the hot-pressing specifically includes the following steps: raise the temperature to 200-220°C and keep it for 0.5-0.7h, then raise the temperature to 240-250°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com