Feedback control circuit

A feedback control and circuit technology, applied in the direction of control/regulation system, electrical components, adjustment of electrical variables, etc., can solve the problems of reducing product efficiency, consumption of voltage regulator tubes, and low withstand voltage value, so as to improve efficiency and reduce no-load The effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

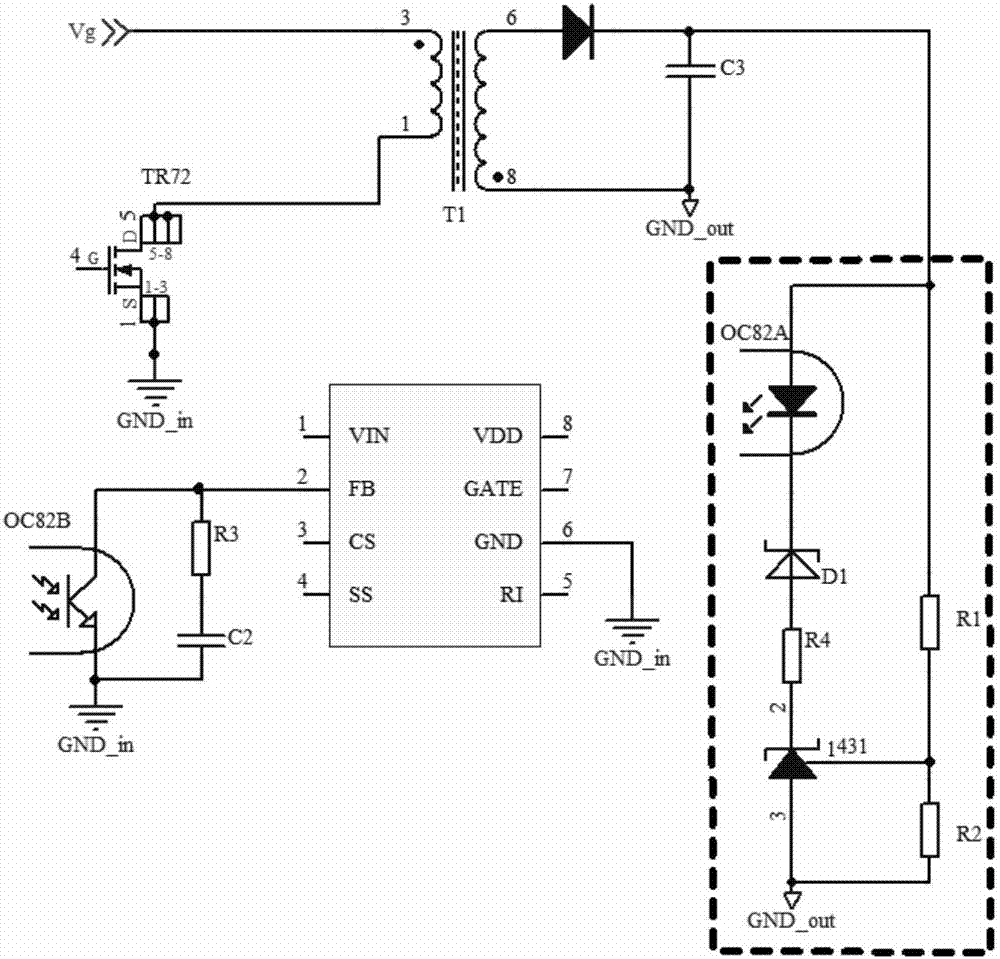

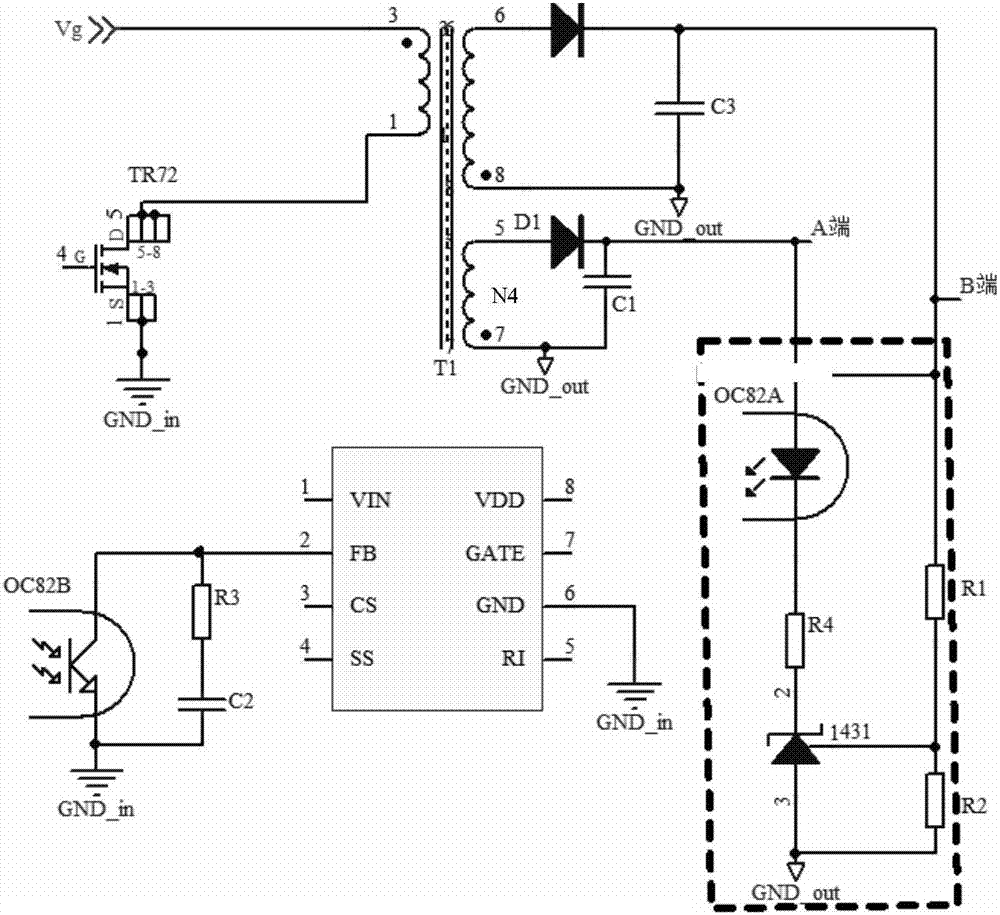

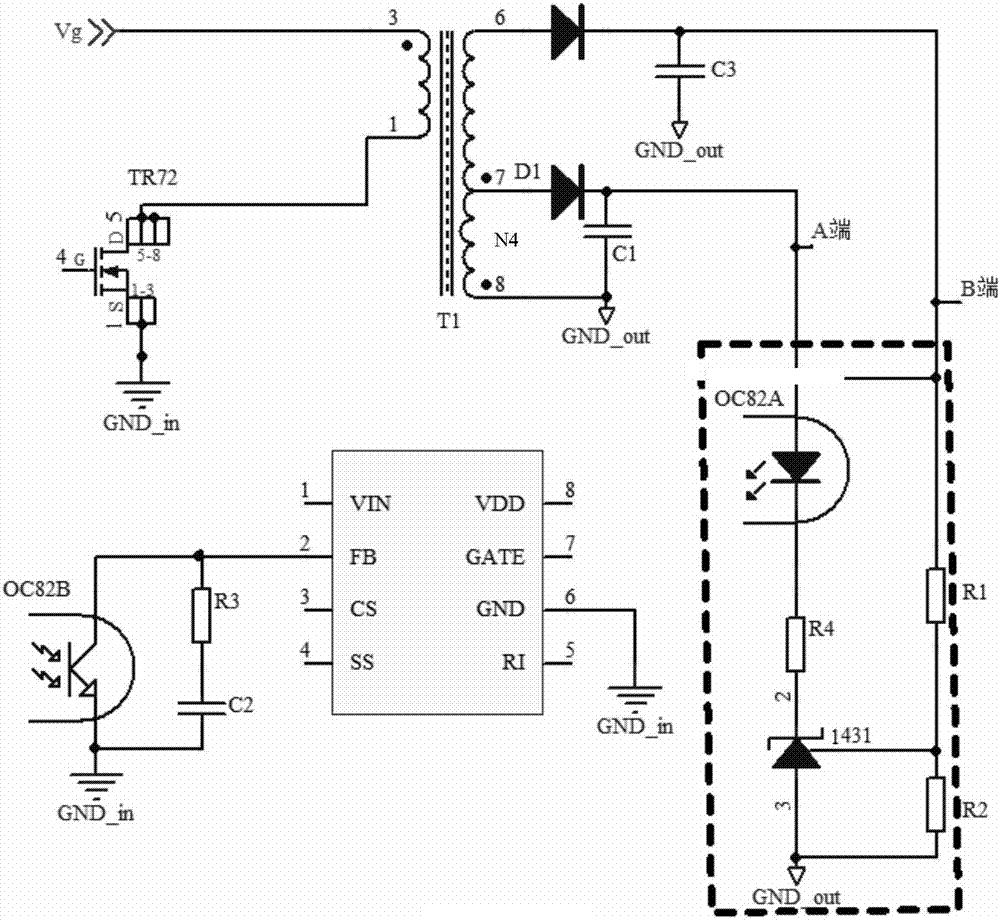

[0020] figure 2 A schematic diagram of the application of the invention is shown.

[0021] A feedback control circuit, including an output feedback winding (auxiliary winding or tapped winding), a filter circuit and a voltage stabilization feedback control unit, the voltage of the output feedback winding follows the voltage of the main power secondary winding, the two have the same polarity and share a common ground , the structure of the feedback winding can be in the form of an auxiliary winding and taking two turns from the main power winding in the form of a tap. The output terminal of the feedback winding is connected to the input terminal of the filter circuit, and a voltage V1 is generated through a filter circuit composed of diodes and capacitors. , the output terminal of the filter circuit is connected to the input terminal A of the voltage stabilization feedback control unit, the input terminal B of the feedback control unit is connected to the positive pole of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com