Preparation method of fire-retardant partition wall for space lease

A partition wall and space technology is applied in the field of preparation of flame retardant partition walls for space leasing, which can solve the problems of high application cost and difficult synthesis of flame retardant and smoke suppressants, achieve high promotion and application value, and reduce production costs and costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a method for preparing a double-layer flame-retardant board, including co-extruding the first material and the second material; wherein, both the first material and the second material contain a flame-retardant and smoke suppressant, wherein, The weight content of the flame retardant and smoke suppressant in the first material is 20%-200% higher than that in the second material; wherein, the flame retardant and smoke suppressant is the flame retardant and smoke suppressant provided by the present invention as described above.

[0034] During this process, the flame retardant and smoke suppressant in the double-layer flame-retardant board of the present invention will not lose its flame-retardant performance during high-temperature processing, and no brittle substances are found. Good mechanical properties, flame retardant, environmental protection. The content of the flame retardant and smoke suppressant in the two layers of the doubl...

Embodiment 1

[0054] Preparation of flame retardant partition walls for space leasing:

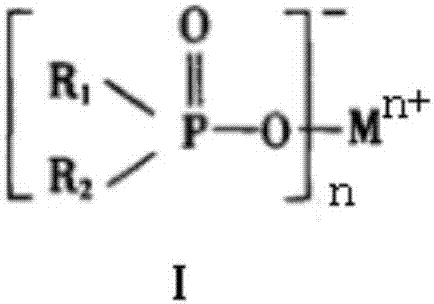

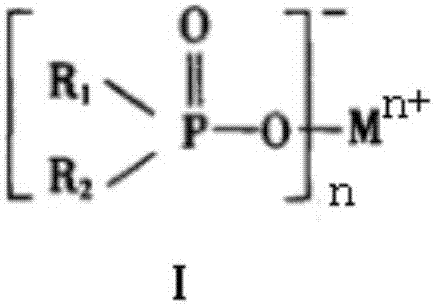

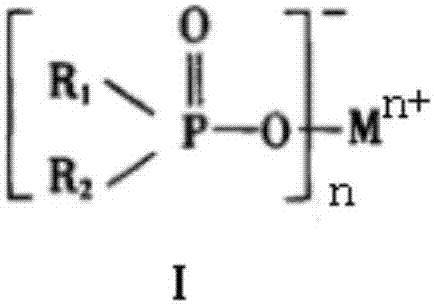

[0055] (1) Preparation of flame retardant and smoke suppressant: in parts by weight, 10 parts of alkylphosphinic acid represented by formula (I), 1 part of tributyltin and 6 parts of tri-n-octylphosphine oxide were mixed at 240°C for 20 minutes, Then keep it warm at 260°C for 1.5h, where, R 1 is methyl; R 2 Be phenyl, M is Al, n is 3, obtains flame retardant and smoke suppressant A1;

[0056] (2) Preparation of double-layer flame-retardant board: in parts by weight, the first material includes: 75 parts of PVC-SG5 type polyvinyl chloride, 100 parts of nanoscale calcium carbonate, 2 parts of dimethyl tin oxide PVC stabilizer, 0.5 parts of stearic acid, 2 parts of ACR K-123 modifier and 15 parts of flame retardant and smoke suppressant A1; the second material includes: 75 parts of PVC-SG5 type polyvinyl chloride, 100 parts of nanometer calcium carbonate, dimethyl 2 parts of tin oxide PVC stabilizer, 0....

Embodiment 2

[0060] Preparation of flame retardant partition walls for space leasing:

[0061] (1) Preparation of flame retardant and smoke suppressant: in parts by weight, 10 parts of alkyl phosphinic acid shown in formula (I), 2 parts of tributyltin and 8 parts of tri-n-octylphosphine oxide were mixed at 245°C for 25 minutes, Then keep it warm at 270°C for 2h, where, R 1 is n-propyl; R 2 It is an isopropyl group substituted by a hydroxyl group at the 1 position, M is Al, and n is 3 to obtain the flame retardant and smoke suppressant A2;

[0062] (2) Preparation of double-layer flame-retardant board body: in parts by weight, the first material to be taken includes: 90 parts of PVC-SG5 type polyvinyl chloride, 125 parts of nanoscale calcium carbonate, 4.5 parts of dimethyl tin oxide PVC stabilizer, 0.8 parts of stearic acid, 2.8 parts of ACR K-123 modifier and 20 parts of flame retardant and smoke suppressant A2; the second material includes: 95 parts of PVC-SG5 type polyvinyl chloride, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com