Combined tower type methanation apparatus and methanation process

A technology of methanation and methanation reactor, which is applied in the field of methanation, can solve the problems of complex process, large land occupation, high energy consumption, etc., and achieve the effects of simplified manufacturing difficulty, high economic benefits, and low comprehensive energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] Fresh raw gas from the upstream purification unit, the characteristic composition is: H 2 : 68.2mol%, CO:19.5mol%, CO 2 :3.0mol%, CH 4 :9.0mol%, N 2 : 0.3mol%.

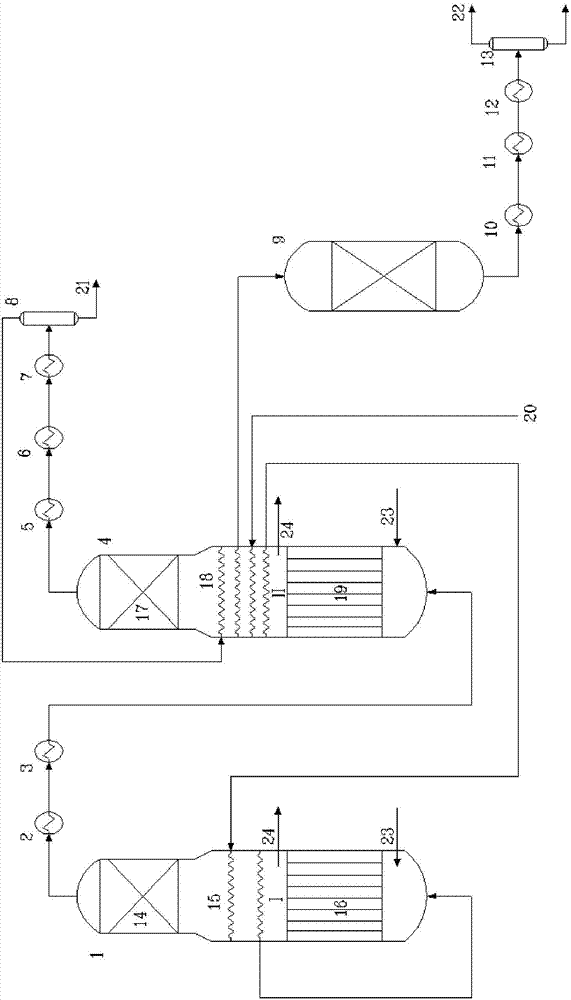

[0033] Such as figure 1 As shown, a methanation process using a composite tower methanation device includes the following steps:

[0034] (1) The fresh feed gas 20 passes through the winding heat exchanger II18 in the middle of the second-stage composite tower methanation reactor II 4, and the heat exchange temperature with the high-temperature gas rises to 130°C, and then enters the first-stage composite tower methanation Intermediate raw material preheater II of reactor I 1 The winding heat exchanger I 15 in the middle part further exchanges heat with the high-temperature gas. After the heat exchange, the raw material gas with a temperature of 280℃ enters the lower part of the first-stage composite tower methanation reactor I 1 I 16 of the isothermal catalyst bed for methanation reaction, the space velocity is 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com