Fluoride-free waterproof finishing emulsion for textiles and application of fluoride-free waterproof finishing emulsion

A fluorine-free waterproof and emulsion technology, applied in fiber processing, textiles and papermaking, and liquid repellent fibers, etc., can solve the problem of product water resistance decline and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

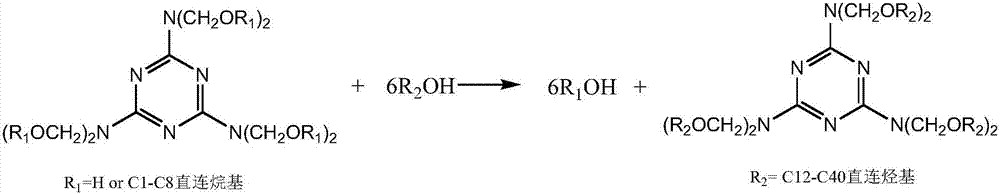

[0067] Synthesis of component a1: Put 39g, 0.1mol of hexamethoxymethylene melamine and 162g, 0.6mol of stearyl alcohol into a 500mL four-neck flask, heat to melt the materials, then add 0.4g of concentrated hydrochloric acid, and continue to heat up to 90°C . When the system began to reflux, the methanol was evaporated under vacuum. After reacting at 90°C for 1.5h, the temperature was raised to 140°C for 2 hours. The product was a colorless and transparent viscous substance, which became a waxy solid after cooling.

Embodiment 2

[0069] Synthesis of component a2: Put 39g, 0.1mol of hexamethoxymethylene melamine and 170g, 0.6mol of octadecanoic acid into a 500mL four-neck flask, heat to melt the materials, then add 0.4g of concentrated hydrochloric acid, and continue to heat up to 90°C . When the system began to reflux, the methanol was evaporated under vacuum. After reacting at 90°C for 1.5h, the temperature was raised to 140°C for 2 hours. The product was a colorless and transparent viscous substance, which became a waxy solid after cooling.

Embodiment 3

[0071] Synthesis of component a3: Put 39g, 0.1mol of hexamethoxymethylene melamine and 188g, 0.6mol of stearyl alcohol into a 500mL four-neck flask, heat to melt the materials, then add 0.4g of concentrated hydrochloric acid, and continue to heat up to 90°C . When the system starts to reflux, add vacuum to distill methanol, and pay attention to controlling the vacuum degree to prevent material flushing. After reacting at 90°C for 1.5h, the temperature was raised to 140°C for 2 hours. The product was a light yellow transparent viscous substance, which became a waxy solid after cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com