A method of strengthening the selective flocculation of fine-grained hematite

A hematite and selective technology, which is applied in the field of enhanced selective flocculation of fine-grained hematite, can solve the problems of environmental pollution, large specific surface area and high surface energy of fine particles, so as to ensure the strength of flocs and improve the quality of flocs , The effect of improving the flocculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

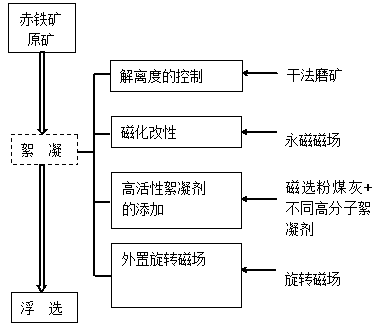

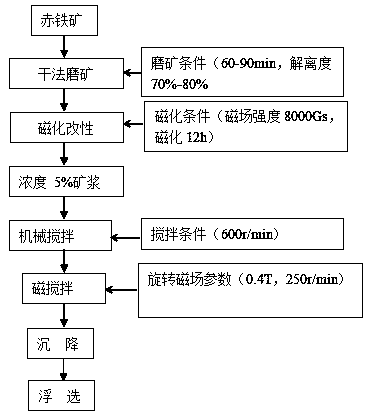

[0029] like figure 1 Shown, is the method roadmap of the present invention, a kind of method for strengthening the selective flocculation of fine-grained hematite of the present embodiment, concrete steps are as follows:

[0030] Step 1, put the hematite into the ball mill and carry out dry grinding, so that the Fe in the hematite 2 o 3 Separate it from other clay minerals as far as possible, and characterize the particle size of hematite particles and the degree of dissociation of hematite particles after grinding; if you blindly pursue a high degree of dissociation, it will inevitably cause overgrinding, and the particle size is too fine. It is not conducive to flocculation in the later stage. The grinding time is controlled at 60-90min, and the hematite particles after grinding with the dissociation degree of hematite monomer between 70% and 80% are selected for use. The appropriate proportion of flocs and intergrowths is not only beneficial to the implementation of magne...

Embodiment 2

[0035] like figure 1 Shown, is the method roadmap of the present invention, a kind of method for strengthening the selective flocculation of fine-grained hematite of the present embodiment, concrete steps are as follows:

[0036] Step 1, put the hematite into the ball mill and carry out dry grinding, so that the Fe in the hematite 2 o 3Separate it from other clay minerals as far as possible, and characterize the particle size of hematite particles and the degree of dissociation of hematite particles after grinding; if you blindly pursue a high degree of dissociation, it will inevitably cause overgrinding, and the particle size is too fine. It is not conducive to flocculation in the later stage. The grinding time is controlled at 60-90min, and the hematite particles after grinding with the dissociation degree of hematite monomer between 70% and 80% are selected for use. The appropriate proportion of flocs and intergrowths is not only beneficial to the implementation of magnet...

Embodiment 3

[0041] like figure 1 Shown, is the method roadmap of the present invention, a kind of method for strengthening the selective flocculation of fine-grained hematite of the present embodiment, concrete steps are as follows:

[0042] Step 1, put the hematite into the ball mill and carry out dry grinding, so that the Fe in the hematite 2 o 3 Separate it from other clay minerals as far as possible, and characterize the particle size of hematite particles and the degree of dissociation of hematite particles after grinding; if you blindly pursue a high degree of dissociation, it will inevitably cause overgrinding, and the particle size is too fine. It is not conducive to flocculation in the later stage. The grinding time is controlled at 60-90min, and the hematite particles after grinding with the dissociation degree of hematite monomer between 70% and 80% are selected for use. The appropriate proportion of flocs and intergrowths is not only beneficial to the implementation of magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com