Single-walled carbon nanotube as well as preparation method and application thereof

A technology of single-walled carbon nanotubes and carbon sources, applied in the direction of single-walled carbon nanotubes, carbon nanotubes, nanocarbons, etc., can solve the problems of low purity and uncontrollable shape of single-walled carbon nanotubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

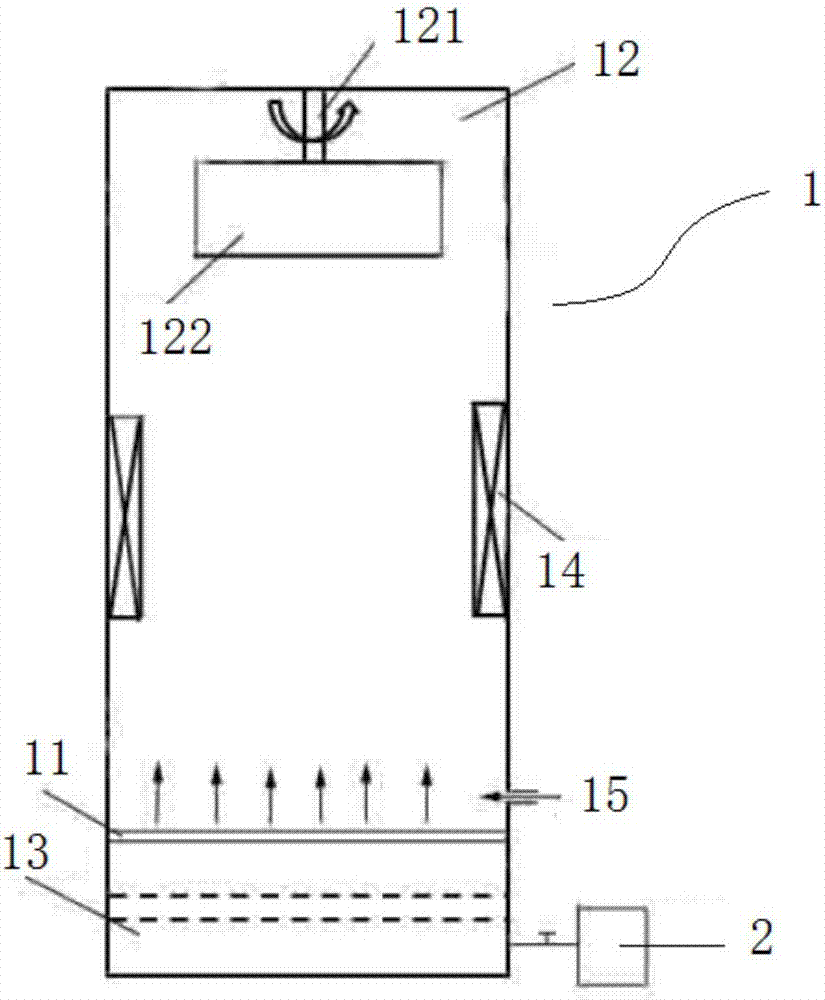

[0029] combine figure 1 , the embodiment of the present invention provides a method for preparing single-walled carbon nanotubes, comprising the following steps:

[0030] Step 1. provide the reaction device that is used to prepare single-walled carbon nanotube, described reaction device comprises the reaction chamber that generates single-walled carbon nanotube, and is used to provide the carbon source supply chamber of carbon source, described reaction chamber is divided into The upper and lower chambers are respectively a reaction chamber and a liquid carbon storage chamber, wherein the liquid carbon source chamber is connected to the carbon source replenishment chamber through a controllable switch; the reaction chamber includes a The rotating shaft provided on the top wall, the rotating shaft is fixedly connected to the base at one end away from the top wall, the inner wall of the reaction chamber is provided with a heating device, and the reaction chamber is provided with...

Embodiment 1

[0062] A method for preparing single-walled carbon nanotubes, comprising the steps of:

[0063] Step 1. Provide as figure 1 The shown reaction device for preparing single-walled carbon nanotubes is vacuumized and inert gas is introduced;

[0064] Step 2. depositing P-doped nickel oxide on the substrate, and injecting ethanol into the liquid carbon storage chamber;

[0065] Step 3. Rotate the shaft at a speed of 15 r / min, and heat at a heating rate of 5° C. / min to evaporate the liquid carbon in the liquid carbon storage chamber;

[0066] Step 4. Continue heating to 700-1000° C. at a heating rate of 20° C. / min, and inject hydrogen to prepare single-walled carbon nanotubes.

Embodiment 2

[0068] A method for preparing single-walled carbon nanotubes, comprising the steps of:

[0069] Step 1. Provide as figure 1 The shown reaction device for preparing single-walled carbon nanotubes is vacuumized and inert gas is introduced;

[0070] Step 2. deposit S-doped Fe, Sn metal oxides on the substrate, and inject citric acid into the liquid carbon storage chamber;

[0071] Step 3. Rotate the rotating shaft at a speed of 25r / min, heat at a heating rate of 8°C / min to evaporate the liquid carbon in the liquid carbon storage chamber;

[0072] Step 4. Continue heating to 700-1000° C. at a heating rate of 25° C. / min, and introduce reducing gas to prepare single-walled carbon nanotubes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com