Microalgae culture system for immobilized culture and deep purifying of wastewater

A technology of immobilized culture and microalgae culture, which is applied in the field of microalgae culture, can solve the problems of limited algae concentration, low yield, and increased costs, and achieve the effects of high implementability, reduced labor intensity, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

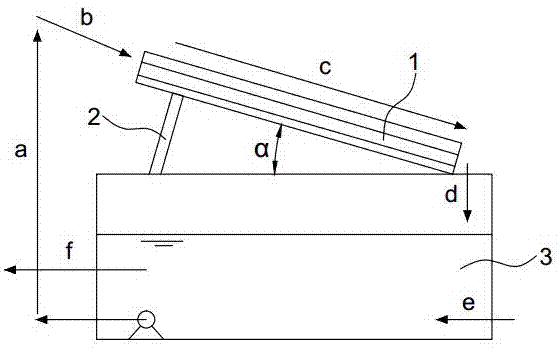

[0031] Such as figure 1 , 5 As shown, a microalgae cultivation system that realizes immobilized cultivation and deep purification of waste water includes a microalgae biofilm cultivator 1 and a circulating water tank 3, the microalgae biofilm cultivator 1 is obliquely connected to the upper end of the circulating water tank 3, and the circulating water tank 3 It is connected to the microalgae biofilm culture device 1 , and a culture plate 8 is connected inside the microalgae biofilm culture device 1 . The preferred inclination angle α of the microalgae biofilm culture device 1 is 18 °, and the inclination angle that the microalgae biofilm culture device 1 is provided with makes the flow velocity of the water flow on the surface of the culture plate 8 suitable, suitable for immobilized cultivation of microalgae, for the best angle of inclination. The microalgae biofilm culture device 1 includes a culture plate 8 , the side wall of the culture plate 8 is connected with a glass...

Embodiment 2

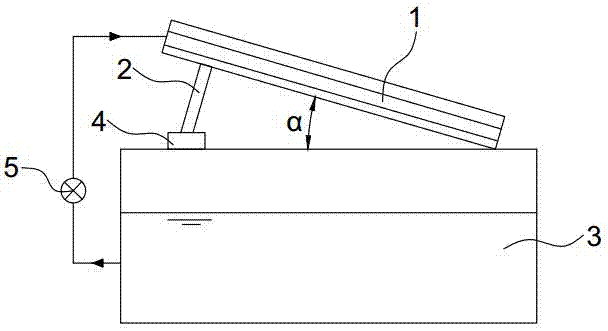

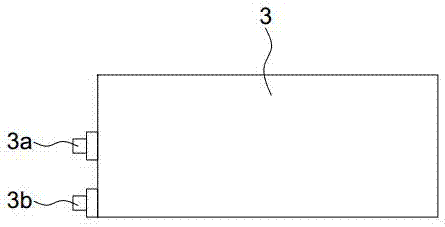

[0035] Such as Figure 2~8 As shown, in this embodiment, on the basis of Example 1, the further optimization scheme is: the microalgae biofilm culture device 1 is obliquely connected to the upper end of the circulating water tank 3 through the supporting column 2, and the connection between the supporting column 2 and the circulating water tank 3 is elastic. Block 4, the circulating water tank 3 is connected to the microalgae biofilm culture device 1 through the water pump 5, and the microalgae biofilm culture device 1 is connected with a culture plate 8 inside. The microalgae biofilm culture device 1 provides microalgae cultivation, and the connection between the microalgae biofilm culture device 1 and the circulating water tank 3 realizes the recycling of the water body inside the circulating water tank 3, which can realize the recycling and purification of waste water or the full utilization of the culture solution , in order to save the cost of microalgae cultivation, wast...

Embodiment 3

[0044]to combine figure 1 The schematic diagram of the system flow and Figure 9 The system flow diagram of the system is a further detailed description of the workflow of this system: the culture medium is evenly distributed on the surface of the microalgae biofilm through the culture medium into the water b, and the microalgae is cultivated c, and the culture after the absorption of the microalgae biofilm The liquid outlet water d flows back into the circulating water tank 3 through the water inlet e of the water tank, and the cultivator extracts the culture solution in the circulating water tank 3 for water quality inspection. The circulating water outlet a is sent back to the culture solution inlet b to re-cultivate the microalgae biofilm. When the water quality monitoring reaches the standard, replace it with a new culture solution until the microalgae biofilm cultivation is completed.

[0045] The conventional technology in this embodiment is the prior art known to thos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com