Bridge pier anti-collision device of metal hollow ball potting resin matrix composite material

A technology of metal hollow balls and composite materials, applied in road safety devices, buildings, roads, etc., can solve the problems of poor energy absorption and protection effect of anti-collision devices, damage and damage of bridge piers, etc. The effect of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

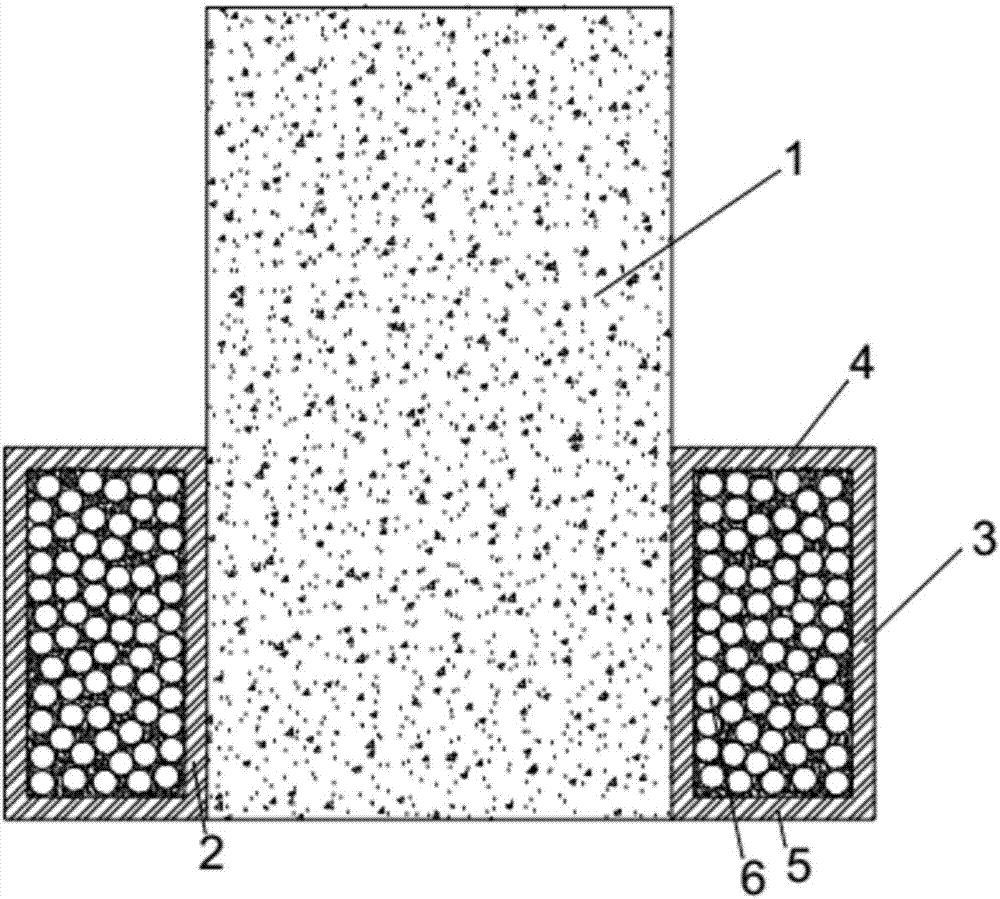

[0021] Specific implementation mode one: combine figure 1 Describe this embodiment in detail. In this embodiment, a bridge pier anti-collision device with metal hollow spheres filled with resin matrix composite materials includes an inner stressed steel plate layer 2, an outer stressed steel plate layer 3, an upper steel plate 4, a lower steel plate 5 and metal Hollow sphere filled resin matrix composite structure layer 6;

[0022] Along the outer circumference of the pier 1, the inner layer of stressed steel plate layer 2, the metal hollow ball filled resin matrix composite material structure layer 6 and the outer layer of stressed steel plate layer 3 are fixed in sequence from the inside to the outside;

[0023] The inner stressed steel plate layer 2, the metal hollow ball filled resin matrix composite material structure layer 6 and the upper end of the outer stressed steel plate layer 3 are fixed with an upper steel plate 4; the inner stressed steel plate layer 2, metal Th...

specific Embodiment approach 2

[0035] Embodiment 2: This embodiment differs from Embodiment 1 in that: the metal hollow ball is made of aluminum. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0036] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the metal hollow sphere has a diameter of 1 cm to 2 cm and a wall thickness of 30 cm to 50 cm. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com