Building construction method of interior wall

A technology for building construction and interior walls, applied in buildings, building components, building structures, etc., can solve the problems of ecological environment damage, large water consumption, waste of water resources, etc., to achieve low equipment failure rate, avoid waste, and avoid pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

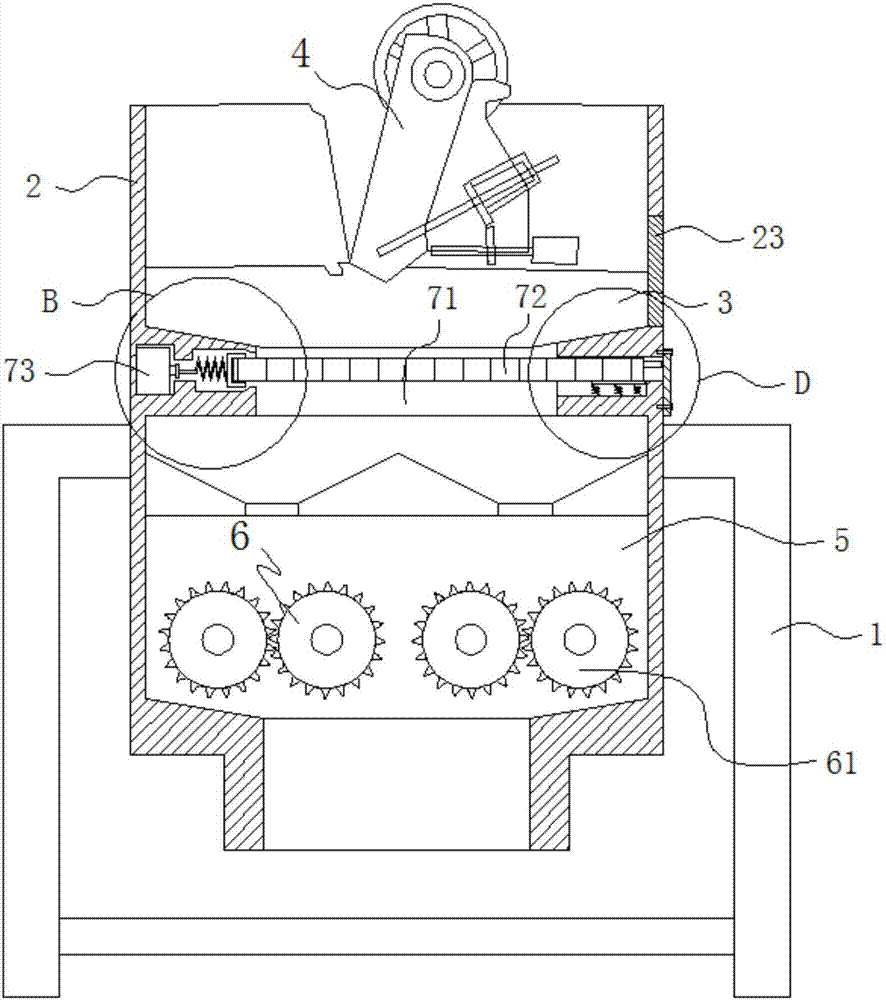

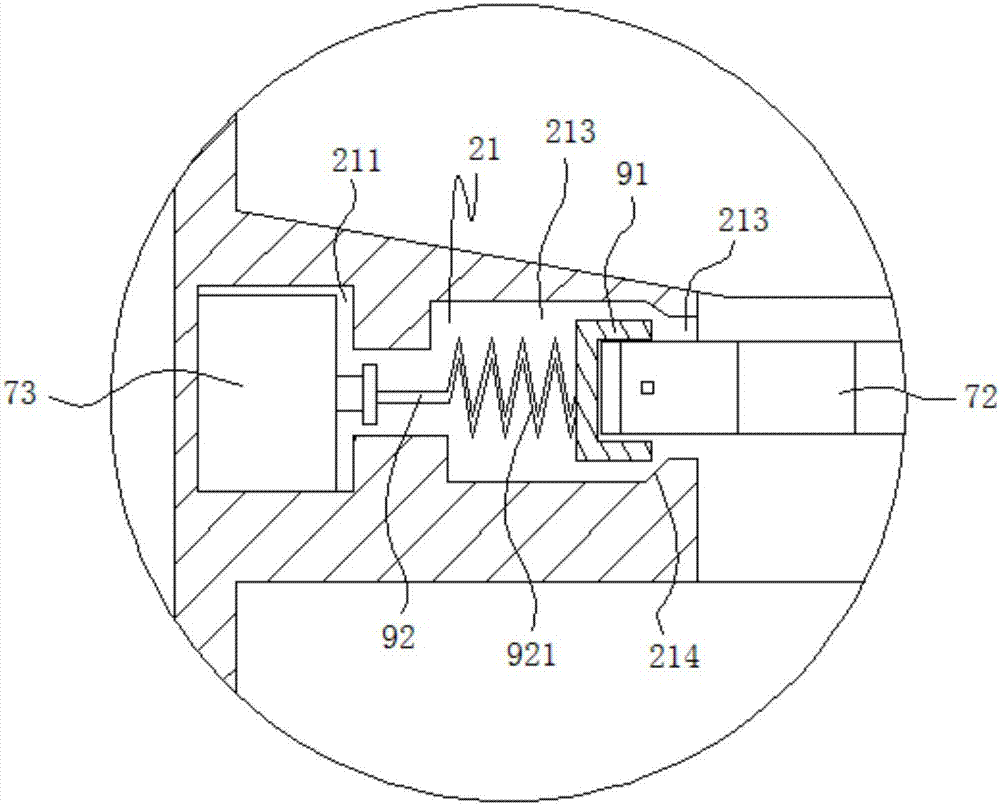

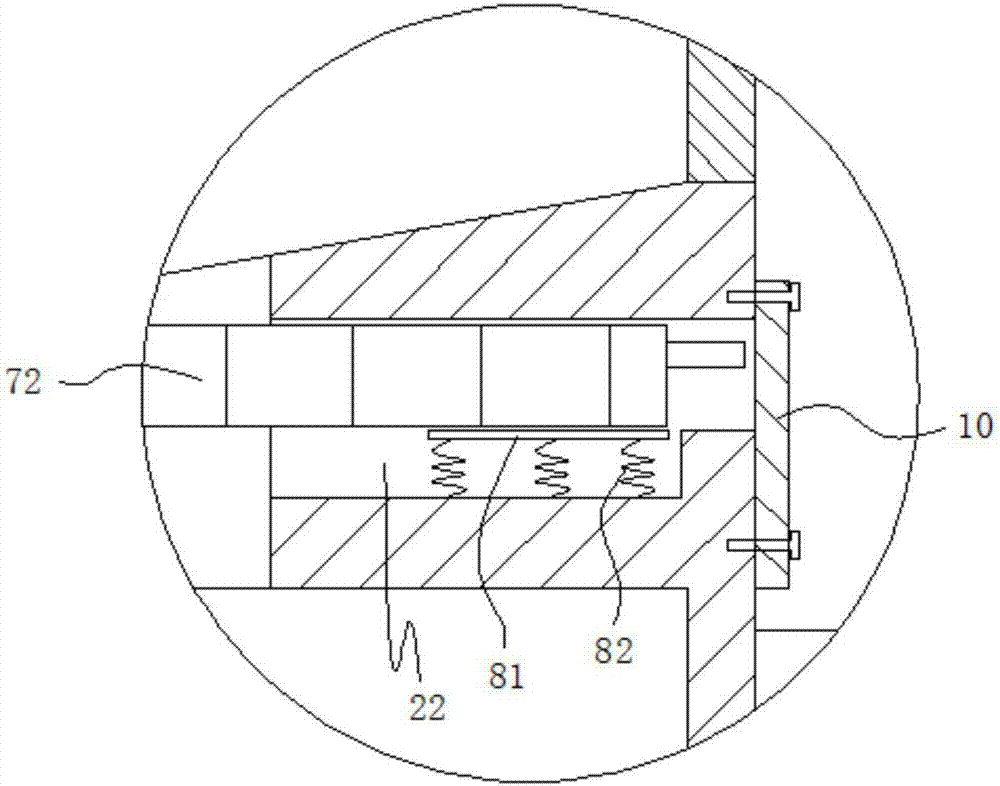

[0030] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

[0031]A building construction method for an interior wall, comprising the following steps: (1) Preparing concrete: crushing construction waste through a crushing device to obtain gravel, wherein the construction waste is discarded concrete blocks and bricks; Stone, sludge, coal ash, cement, water, and water reducing agent are put into the mixer, and the raw material A is obtained after uniform mixing by the mixer; specifically, the sludge, coal ash, crushed stone, cement, water, water reducing agent The weight ratio of the water agent is 0.3:0.2:3.5:2.5:2:0.1, the specific weight can be adjusted according to the actual production, and there is no specific limit here; then add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com