A conductive metal-organic framework for resistive gas sensors

A gas sensor and organic framework technology, applied in the fields of materials, electronics, and chemistry, can solve problems such as slow response speed, non-room temperature operation, and long recovery time, and achieve good stability, good repeatability, and simple preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

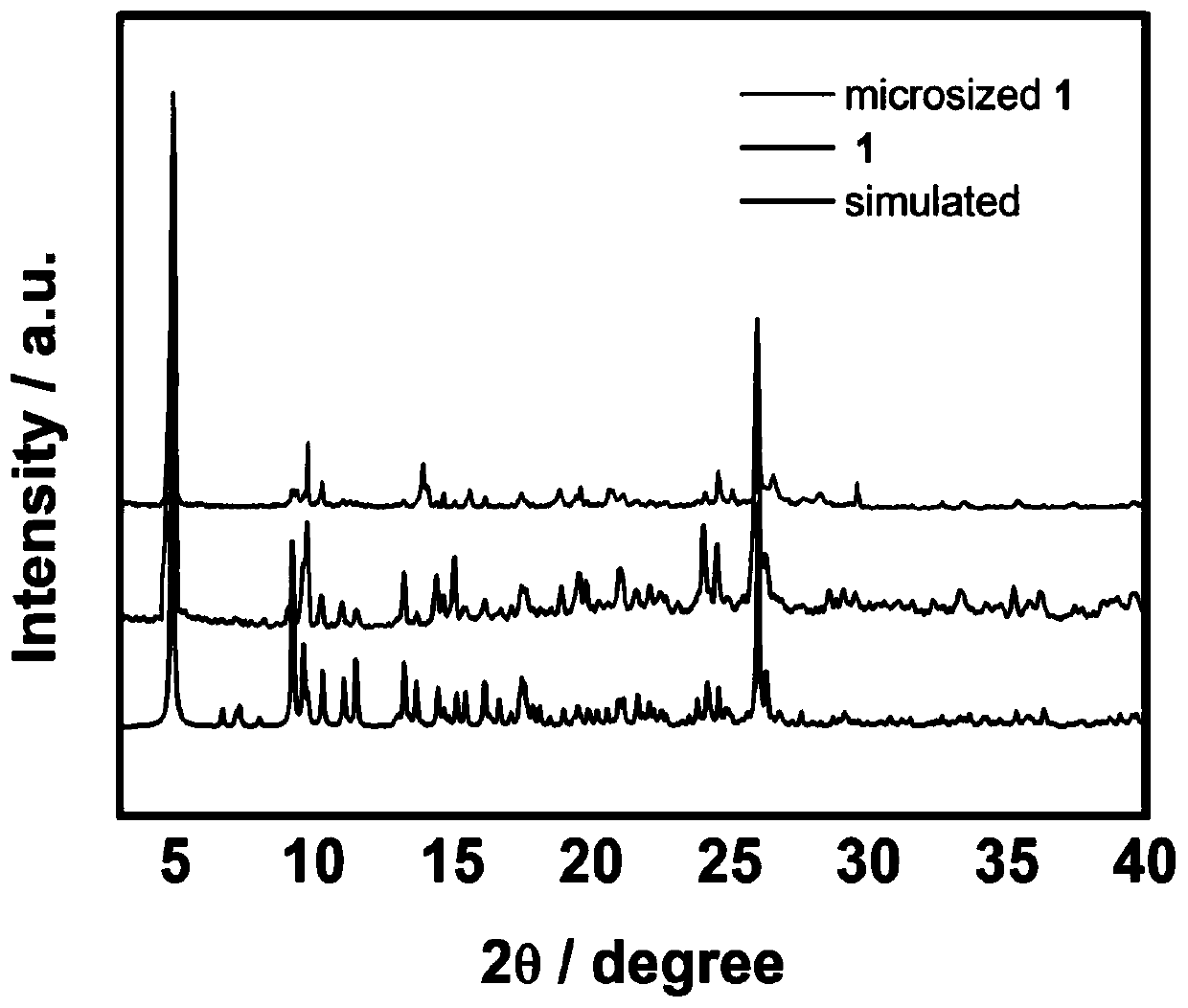

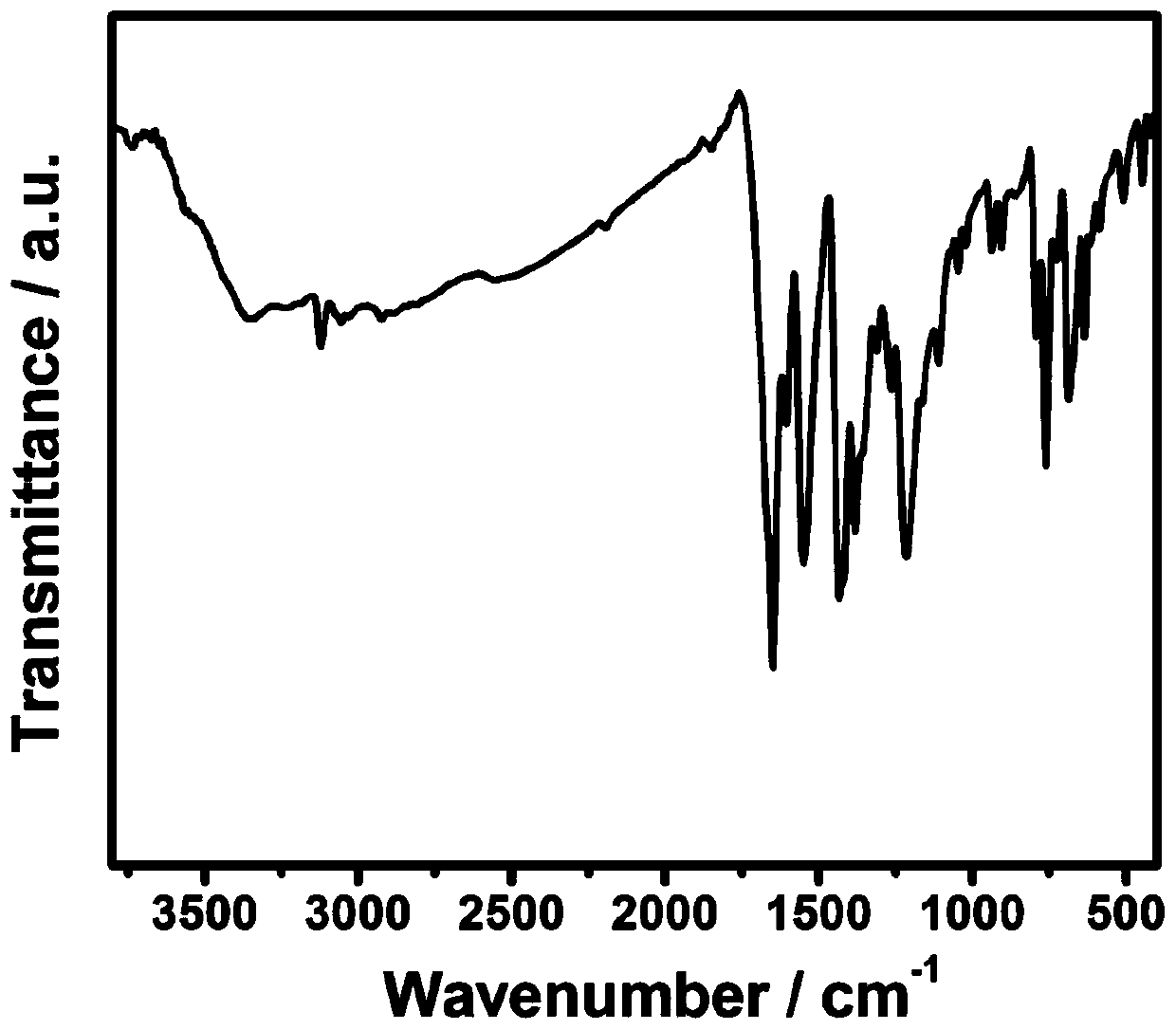

[0028] Preparation of new conductive metal-organic framework materials: Take 0.08mmol In(NO 3 ) 2 4H 2 O, 0.016mmol 9,10-bis(ethynylpyridine)anthracene was added to the reaction vessel, and 2.4×10 -3 mol N,N'-dimethylformamide (DMF) and 1.6×10 -3 mol HNO 3 , and then put the bottle into an oven at 100°C to react for 120 hours to obtain a crude indium metal organic framework; wash the crude indium metal organic framework with DMF and dry at 100°C to obtain an orange flake crystalline metal organic framework, The yield was 70% (calculated based on the amount of organic ligand).

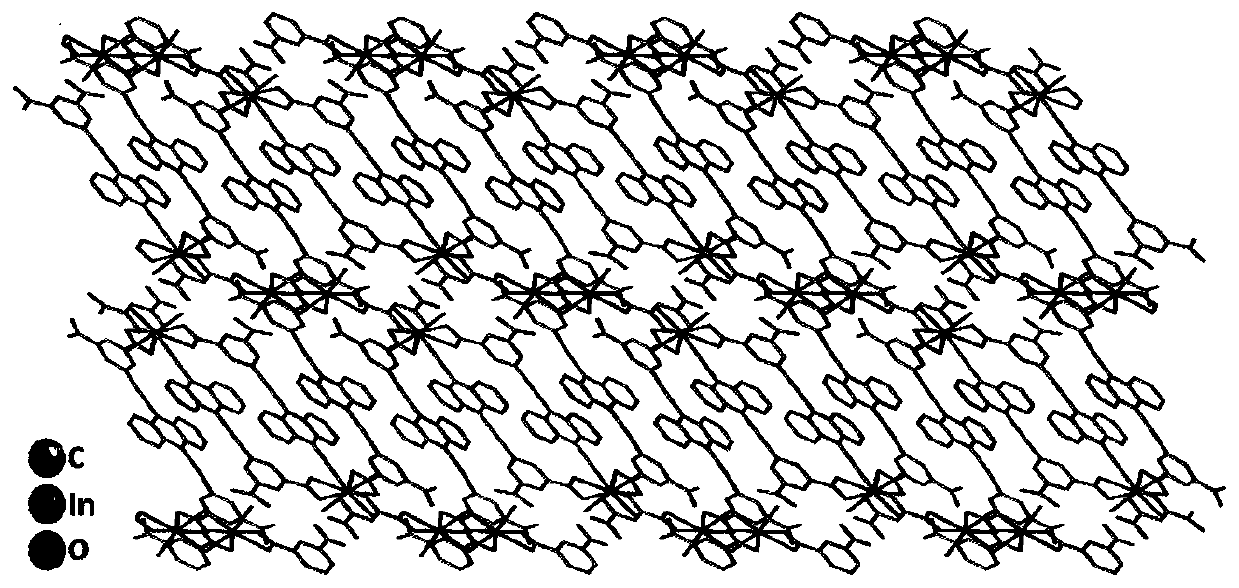

[0029] The unit cell parameters of the novel indium metal organic framework material are 12.954(2), 14.453(5), 18.956(4), 102.510(12), 94.165(8), and 109.364(7). The novel indium metal organic framework material belongs to the triclinic crystal system and the P-1 space group.

[0030] The structural schematic diagram of the novel indium metal organic framework material is shown in figure 1 , whic...

Embodiment 2

[0035] Take 0.018mmol In(NO 3 ) 2 4H 2 O, 0.009mmol 9,10-bis(ethynylisophthalic acid)anthracene was added to the vial, and 2.4×10 -3 mol N,N'-dimethylformamide (DMF) and 1.6×10 - 3 molHNO 3 , and then put the reaction container in an oven at 100°C for 120h to obtain the crude indium metal organic framework; wash the crude indium metal organic framework with DMF and dry at 60°C to obtain orange-yellow strip crystals—purified The indium metal organic framework material has a yield of 25% (calculated based on the amount of organic ligands).

Embodiment 3

[0037] Take 0.018mmol In(NO 3 ) 2 4H 2 O, 0.036mmol 9,10-di(ethynyl isophthalic acid)anthracene was added to the reaction vessel, and 2.4×10 -3 mol N,N'-dimethylformamide (DMF), and 1.6×10 - 3molHNO 3 , and then put the reaction container into an oven at 100°C for 120 hours to react to obtain the crude indium metal organic framework; wash the crude indium metal organic framework with DMF and dry at 60°C to obtain orange-yellow strip crystals—purified The indium metal organic framework material has a yield of 35% (calculated based on the amount of organic ligands).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com