Piezoelectric friction electric hybrid wearable nano generator and preparation method thereof

A nanogenerator and triboelectric technology, applied in the field of nanomaterials, can solve problems such as difficult operation, complex process, and difficulty in large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

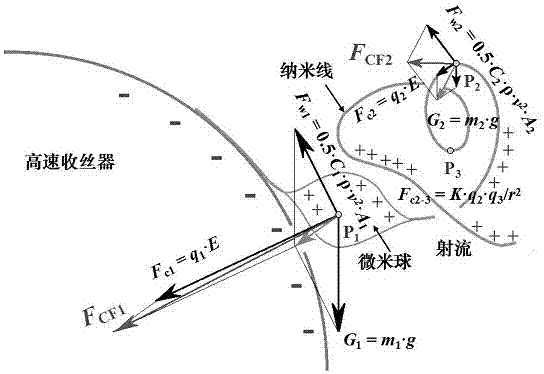

[0052] (1) Measure 9 mL of N,N-dimethylformamide and 6 mL of acetone into a beaker, add 1.4013 g of polymer powder into it, stir magnetically for 60 min, and let stand for 60 min to obtain uniform and foam-free spinning liquid;

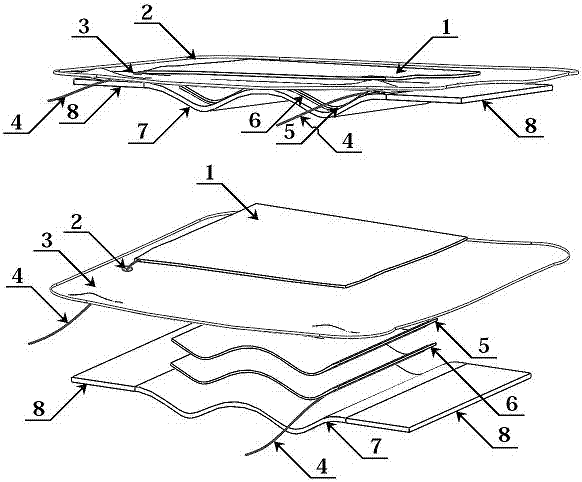

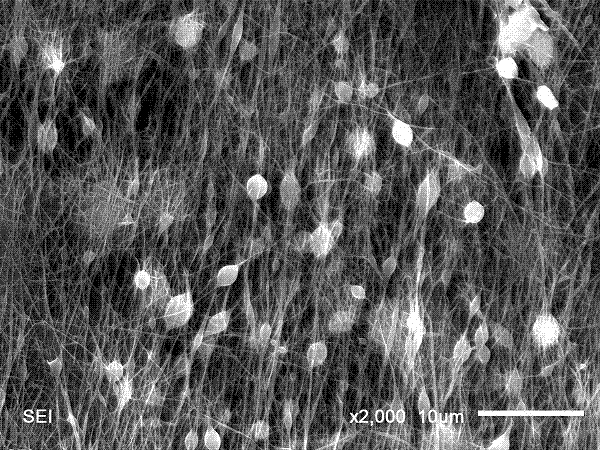

[0053] (2) The above-mentioned spinning dope was subjected to a positive voltage of 15 kV, a negative voltage of -2.5 kV, a spinning speed of 1 mL / h, a distance of 8 cm from the needle to the receiver, and a rotational speed of the receiver of 2800 rpm. Electrospinning was carried out under the condition of spinning time of 300 min to obtain a non-woven fabric with a thickness of 30 μm, piezoelectricity and nanowire-coated microsphere structure. The non-woven fabric was cut into length and width of 42 Small pieces of mm;

[0054] (3) A piece of conductive fiber cloth with a thickness of 143 μm and a length and width of 40 mm is used as the first electrode 1; a nitrile rubber with a thickness of 85 μm and a length and width of 50 mm is used as the ela...

Embodiment 2

[0059] (1) Measure 10 mL of N,N-dimethylformamide and 5 mL of acetone into a beaker, add 1.3547 g of polymer powder into it, stir magnetically for 30 min, and let stand for 30 min to obtain uniform and foam-free spinning liquid;

[0060] (2) The above-mentioned spinning solution was subjected to a positive voltage of 15 kV, a negative voltage of -2.5 kV, a spinning rate of 1 mL / h, a distance from the needle to a receiver of 10 cm, and a rotational speed of the receiver of 2800 rpm. Electrospinning was carried out under the condition of spinning time of 230 min to obtain a non-woven fabric with a thickness of 20 μm, piezoelectricity and nanowire-coated microsphere structure. The non-woven fabric was cut into length and width of 42 Small pieces of mm;

[0061] (3) A piece of conductive fiber cloth with a thickness of 143 μm and a length and width of 40 mm was used as the first electrode 1; a nitrile rubber with a thickness of 85 μm and a length and width of 50 mm was used as th...

Embodiment 3

[0066] (1) Take 9 mL of N,N-dimethylformamide and 5 mL of acetone in a beaker, add 1.4567 g of polymer powder into it, stir magnetically for 60 minutes, and let it stand for 30 minutes to obtain uniform and foam-free spinning liquid;

[0067] (2) The above-mentioned spinning dope was subjected to a positive voltage of 20 kV, a negative voltage of -2.5 kV, a spinning speed of 1 mL / h, a distance of 8 cm from the needle to the receiver, and a rotational speed of the receiver of 2800 rpm. Electrospinning was carried out under the condition of spinning time of 260 min to obtain a non-woven fabric with a thickness of 24 μm and a piezoelectricity and nanowire-coated microsphere structure. The non-woven fabric was cut into a length and width of 42 Small pieces of mm;

[0068] (3) A piece of conductive fiber cloth with a thickness of 143 μm and a length and width of 40 mm was used as the first electrode 1; a nitrile rubber with a thickness of 85 μm and a length and width of 50 mm was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com